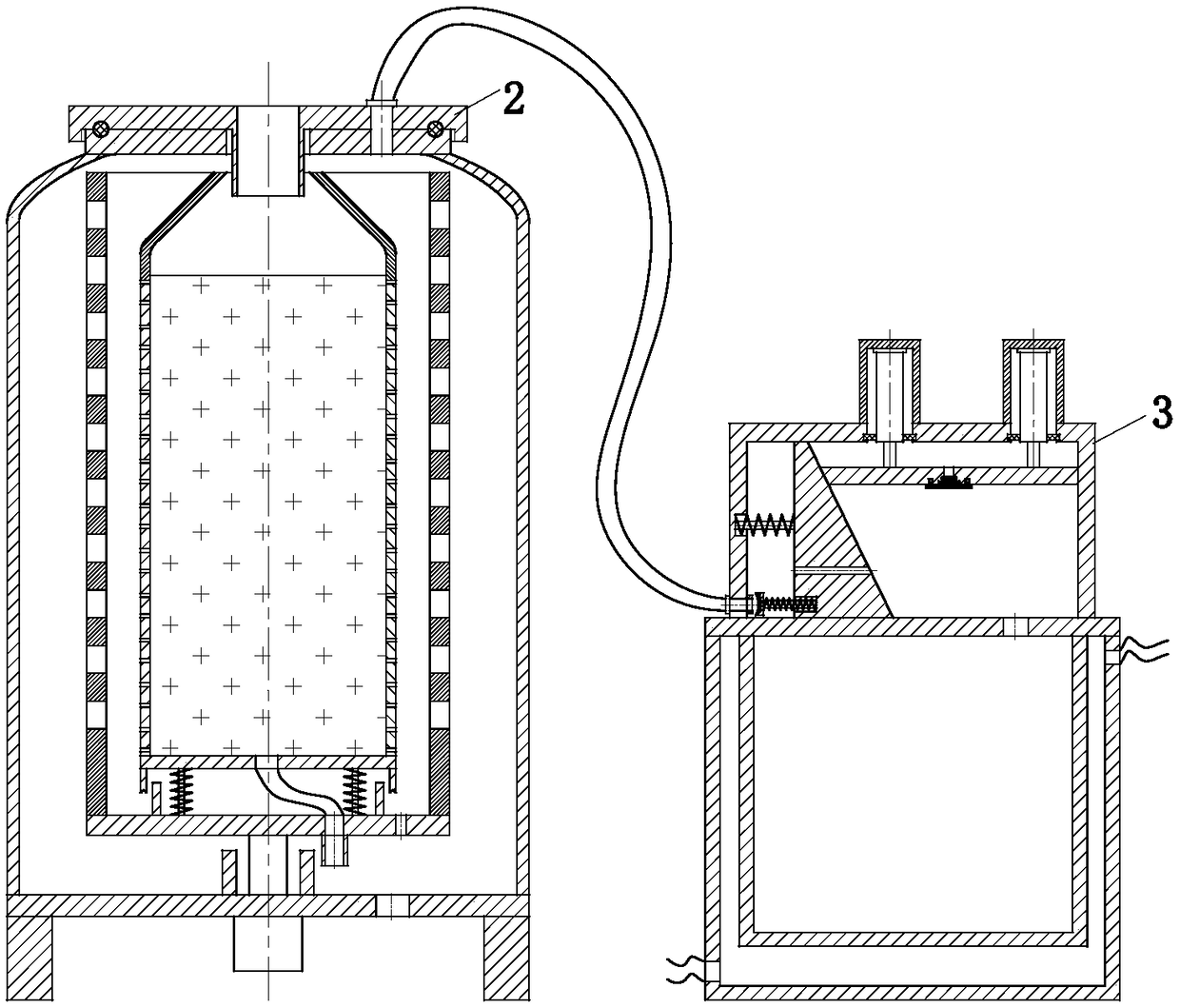

Liquid alcohol extracting and collecting system

A collection system and liquid ethanol technology, applied in the field of winemaking, can solve problems such as low alcohol collection efficiency and alcohol flavor damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

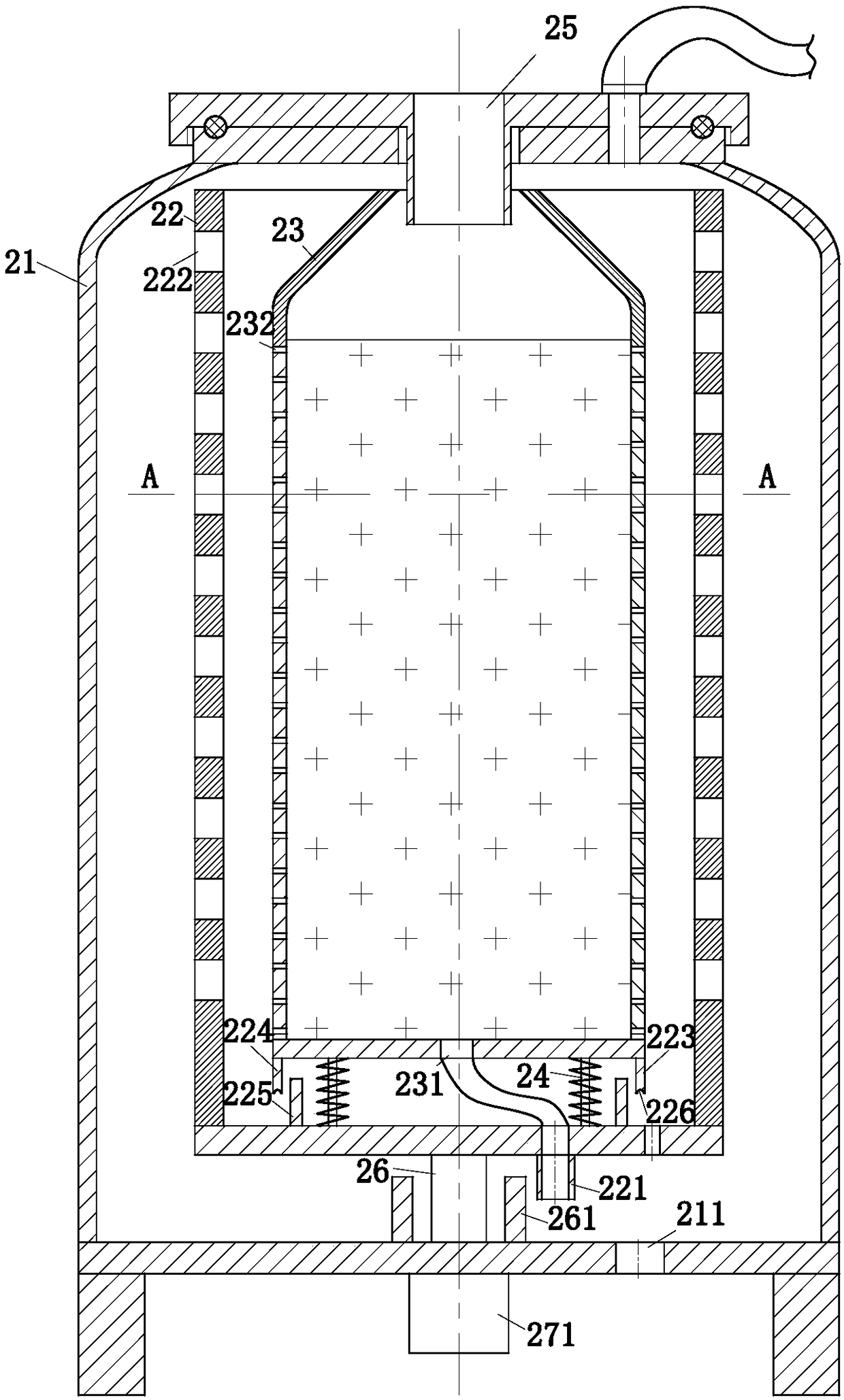

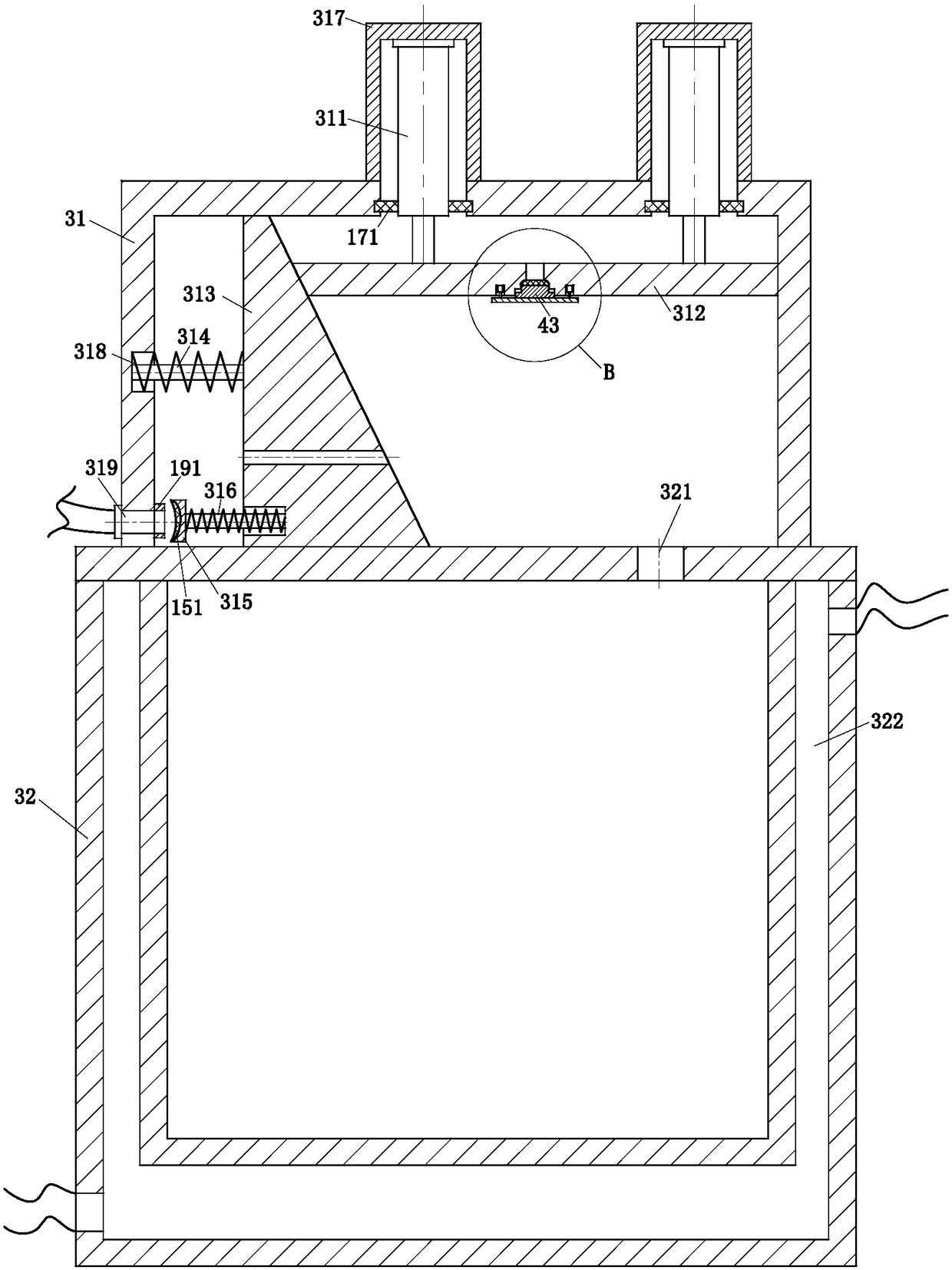

[0023] As an embodiment of the present invention, the drainage unit 223 includes a No. 1 drainage tube 224 and a No. 2 drainage tube 225. The No. 1 drainage tube 224 is installed on the lower surface of the No. 2 horn tube 23, and the No. 1 drainage tube 224 The bottom is coaxially provided with No. 2 drainage tube 225; the No. 2 drainage tube 225 is fixedly installed above the bottom surface of the horn 22, and the diameter of the No. 2 drainage tube 225 is smaller than the diameter of the No. 1 drainage tube 224; The lower surface of the drainage tube 224 is provided with a No. 3 annular groove 226 with a semicircular cross-section. The No. 3 annular groove 226 is used to prevent liquid from flowing along the side wall of the No. 1 drainage tube 224 .

[0024] As an embodiment of the present invention, the cross-sectional shape of the No. 2 air vent 222 is a parallelogram structure, the inclination direction of the No. 2 air vent 222 is consistent with the rotation direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com