Steam generating device for avoiding dripping during flat ironing and ironer

A technology for a steam generating device and an ironing machine, which is applied to washing devices, laundry room devices, and wrinkle-removing and flattening equipment, etc., can solve the problems of low temperature of ironing panels, reduced steam release, dripping water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings of the description.

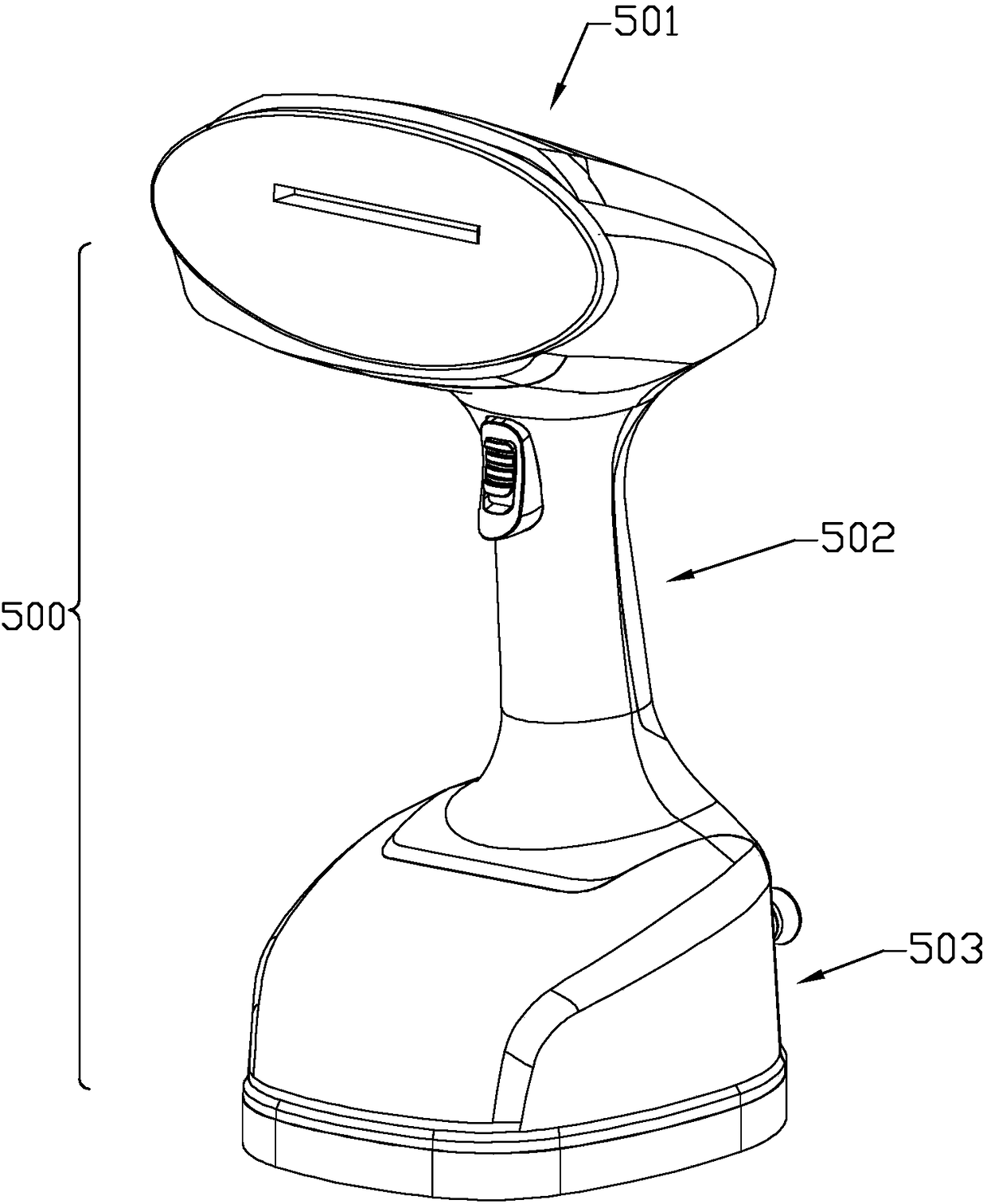

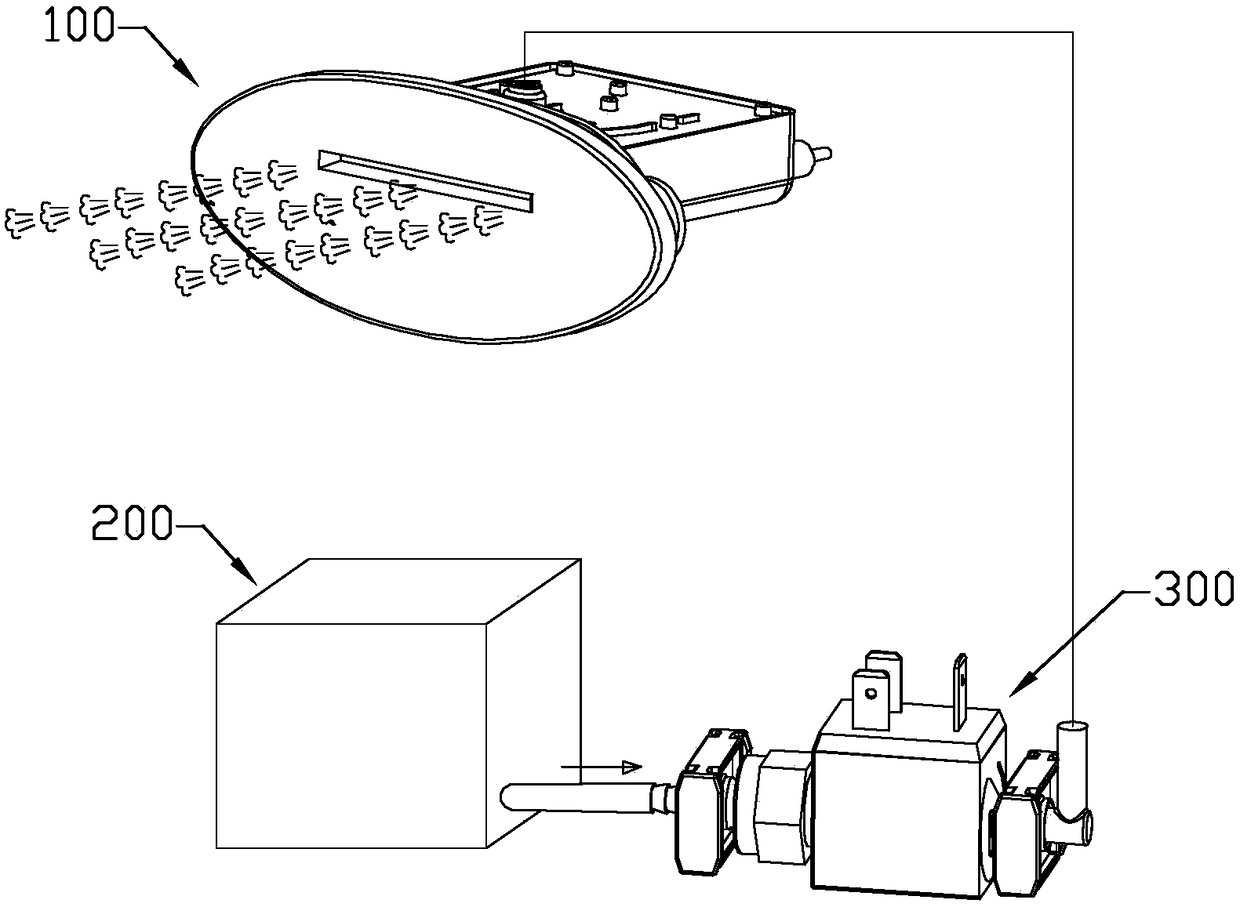

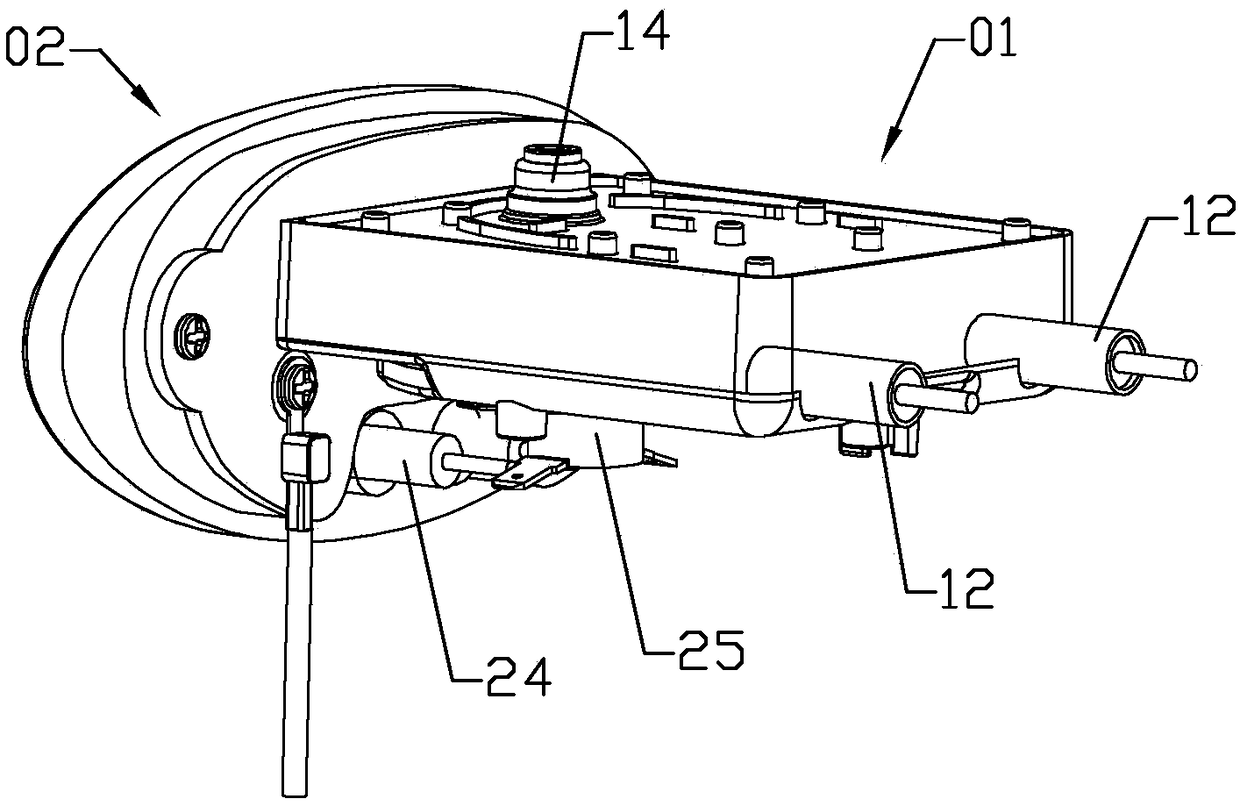

[0041] Such as Figure 3-6 , Figure 9 As shown, the steam generating device for avoiding water dripping during flat ironing includes a gas furnace 01 and an ironing panel 02. The gas furnace 01 includes a furnace body 11 and a first electric heating device 12 buried in the furnace body. The interior of the furnace body 11 is equipped with There is a first vaporization flow channel 13 (see Figure 8 , where the line marked with the arrow indicates the flow direction), the furnace body 11 is provided with a water inlet 14 and a steam outlet 15, the water inlet 14 is connected to the initial end of the first vaporization flow channel 13, and the steam outlet 15 is connected to the first vaporization At the end of the flow channel 13, the ironing panel 02 has a steam exhaust port 21, the ironing panel 02 is assembled on the vaporization furnace 01, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com