A beam-column joint reinforcement avoidance structure and construction method thereof

A beam-column node and node technology, which is applied to building structures, buildings, etc., can solve the problems of increasing the spacing of steel bars, increasing the installation of prefabricated parts, and difficult to unify the bending shape of steel bars, so as to simplify the installation process and simplify the complexity. , the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

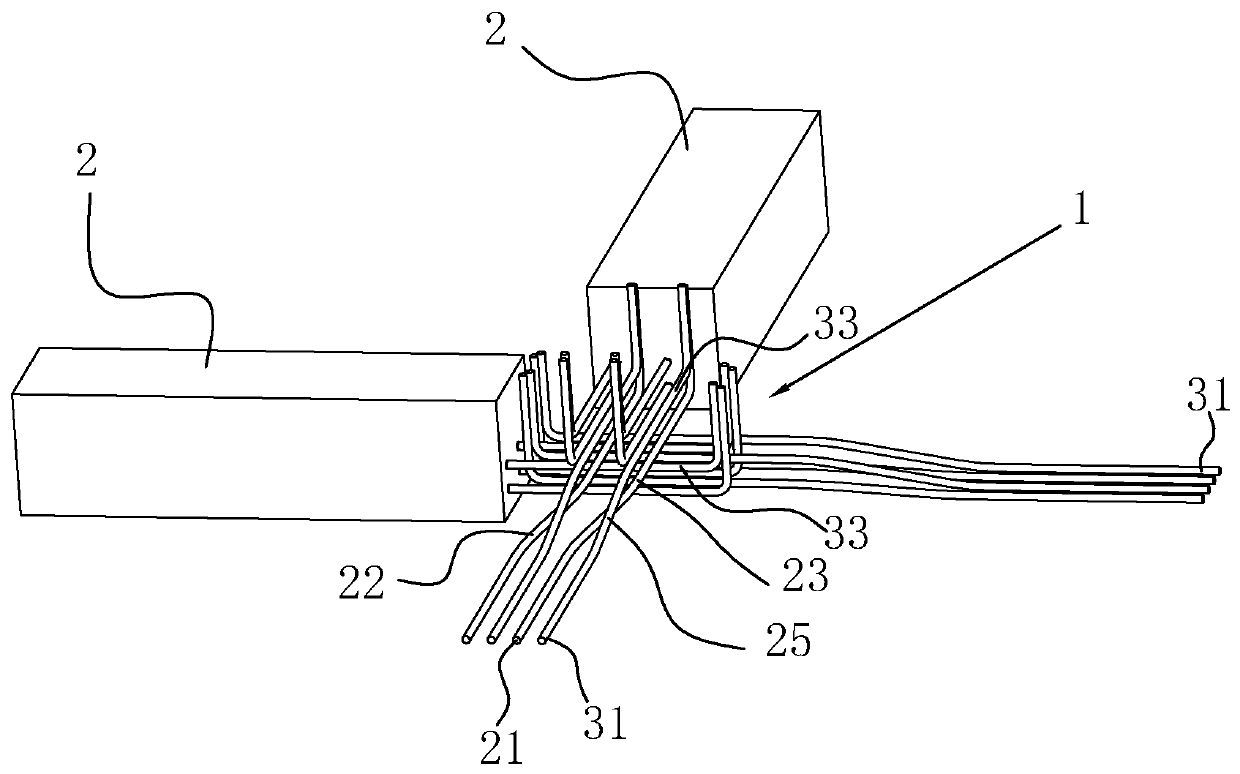

[0055] A beam-column node steel bar avoidance structure, according to the requirements of the concrete specification, the minimum clear distance of the longitudinal bars at the bottom of the prefabricated beam 2 is max (25, d), where d is the diameter of the longitudinal bars, because the commonly used longitudinal bars of beam bars They are all below 25mm. In this embodiment, in order to consider the standardization requirements, the longitudinal reinforcement at the bottom of the beam only considers the situation below 25mm, and the spacing of the steel bars is taken as 50mm to meet the requirements of the standard steel bar spacing.

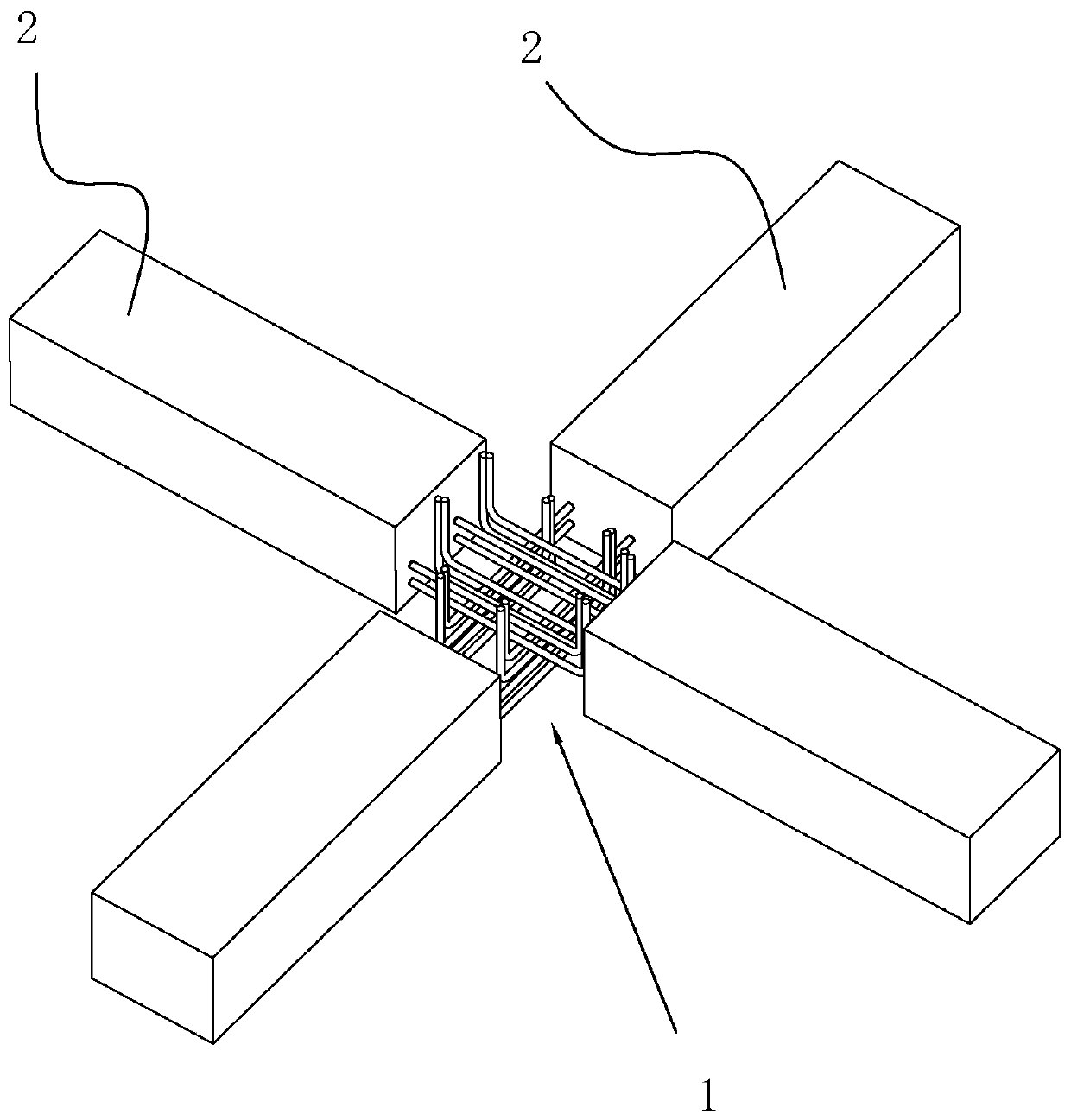

[0056] refer to figure 1 and figure 2 , including the node 1 and the prefabricated beam 2 where the node 1 intersects. The two sides of the node 1 are overlapped with the prefabricated beam 2 respectively, and the four prefabricated beams 2 are arranged in the shape of a "cross". A row of longitudinal ribs arranged along the length direction...

Embodiment 2

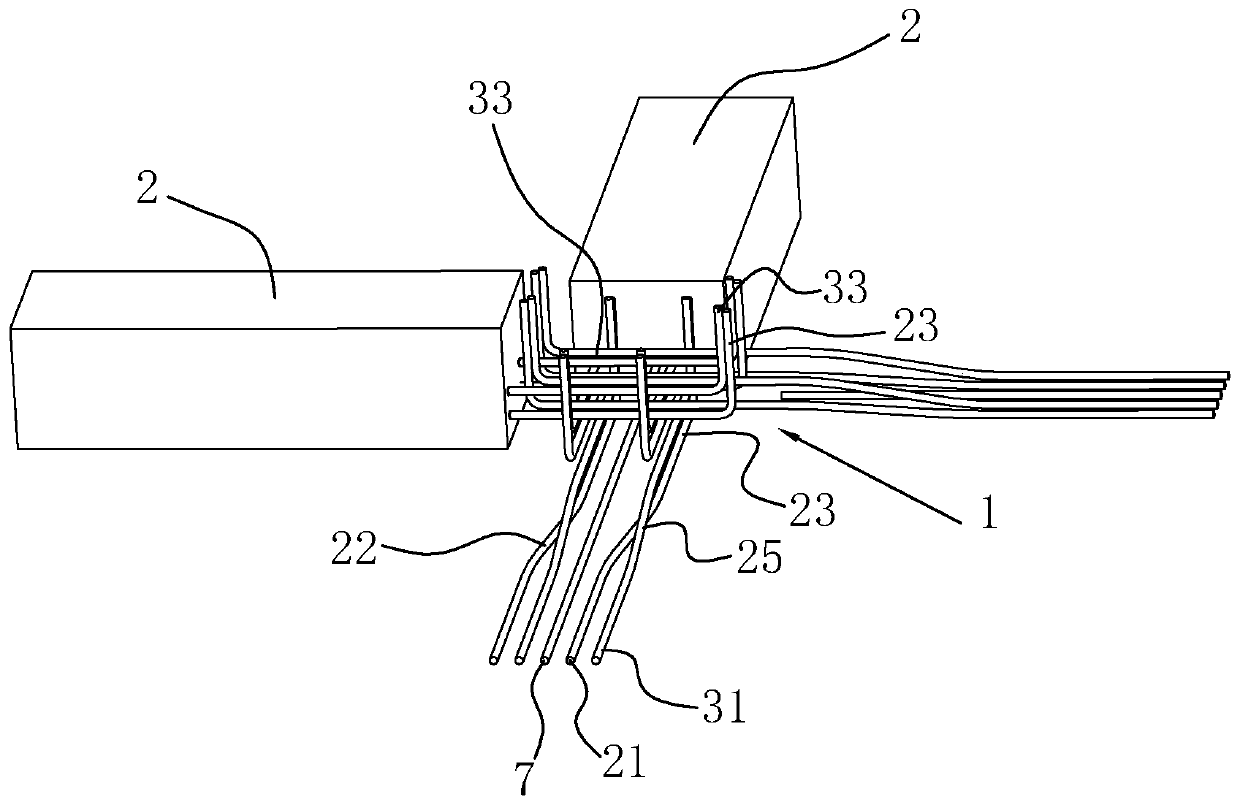

[0058] This embodiment is used to illustrate the situation when the number of longitudinal ribs in the prefabricated beam 2 is an odd number, that is, the first longitudinal ribs 21 and the second longitudinal ribs 31 cannot match each other.

[0059] A beam-column node steel bar avoidance structure, according to the requirements of the concrete specification, the minimum clear distance of the longitudinal bars at the bottom of the prefabricated beam 2 is max (25, d), where d is the diameter of the longitudinal bars, because the commonly used longitudinal bars of beam bars They are all below 25mm. In this embodiment, in order to consider the standardization requirements, the longitudinal reinforcement at the bottom of the beam only considers the situation below 25mm, and the spacing of the steel bars is taken as 50mm to meet the requirements of the standard steel bar spacing.

[0060] refer to figure 1 and image 3 , including the node 1, including the prefabricated beam 2 th...

Embodiment 3

[0062] A construction method for a beam-column node reinforcement avoidance structure, comprising the following steps:

[0063] Fabrication of steel molds for prefabricated components: According to the design drawings, the steel formwork of the components to be prefabricated is produced. In this embodiment, the formwork of the prefabricated components is made of steel formwork. The steel formwork has high strength, high manufacturing precision and can be recycled for many times. , during the processing of the steel formwork, the steel formwork is processed according to the processing technology of the steel formwork and the material type specifications of the construction drawings;

[0064] Reinforcement layout of prefabricated components: set up the prefabricated steel formwork in the prefabrication factory, arrange the longitudinal reinforcement according to the specification, then set the stirrup outside the longitudinal reinforcement, and carry out the first longitudinal re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com