Film disc coupler with overload protection function

An overload protection and coupling technology, which is applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problem of not being able to provide large axis offset compensation at the same time, so as to avoid overload damage of the diaphragm and high torque Effects of transmission, high power and torque transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

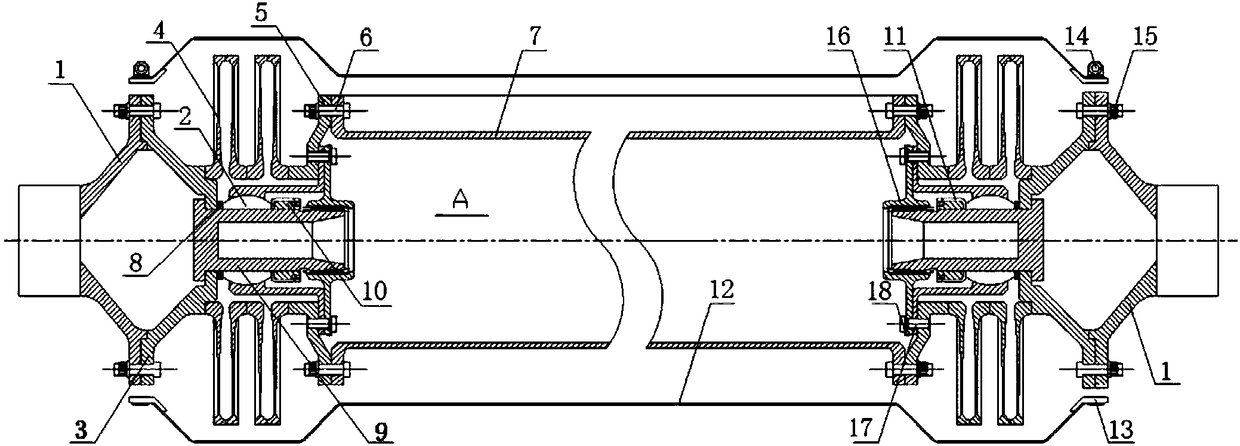

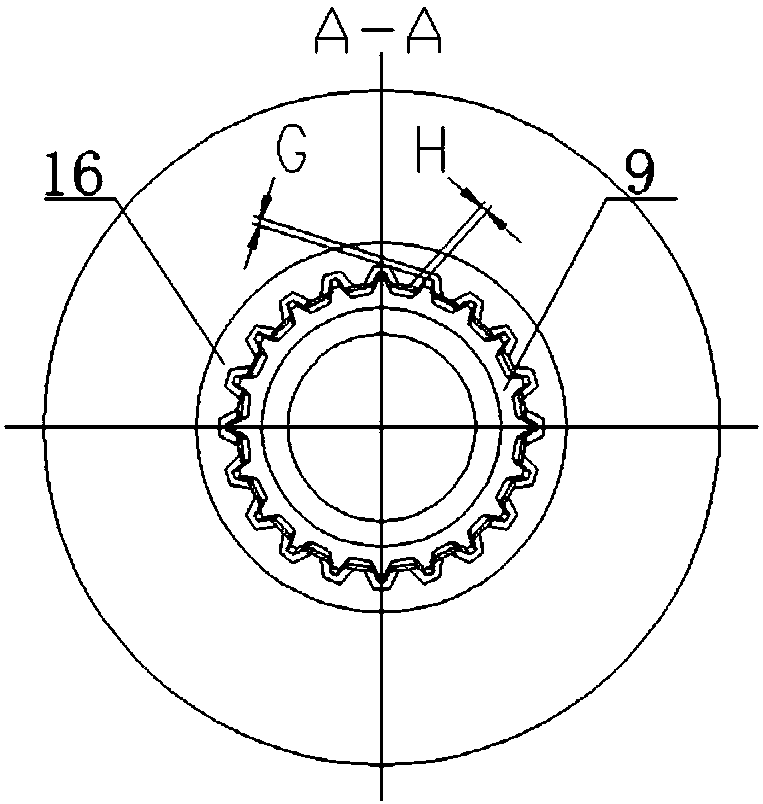

[0021] Please refer to the attached figure 1 , the present invention includes a symmetrically distributed coupling shaft 1, an integrated joint bearing (2), a flange (3), a diaphragm group (4), an adapter section (5), a coupling bolt (6), and a spacer shaft (7 ), adjusting pad (8), inner shaft (9), compression nut (10), lock plate (11), protective cover (12), support ring (13), clamp group (14), self-locking nut ( 15), outer mounting shaft (16), connecting screw (17) and locking plate (18).

[0022] Please refer to the attached figure 1 , the diaphragm group (4) formed by welding 4 single diaphragm discs, one end face is connected with the flange plate (3) through welding, and the other end face is connected with the transfer section (5) through welding, and the inner shaft (9 ) into the inner hole of the flange (3), install the adjusting pad (8) and the integrated joint bearing (2) on the inner shaft 11 in sequence, and compress the axial direction with the compression nut ...

Embodiment approach 2

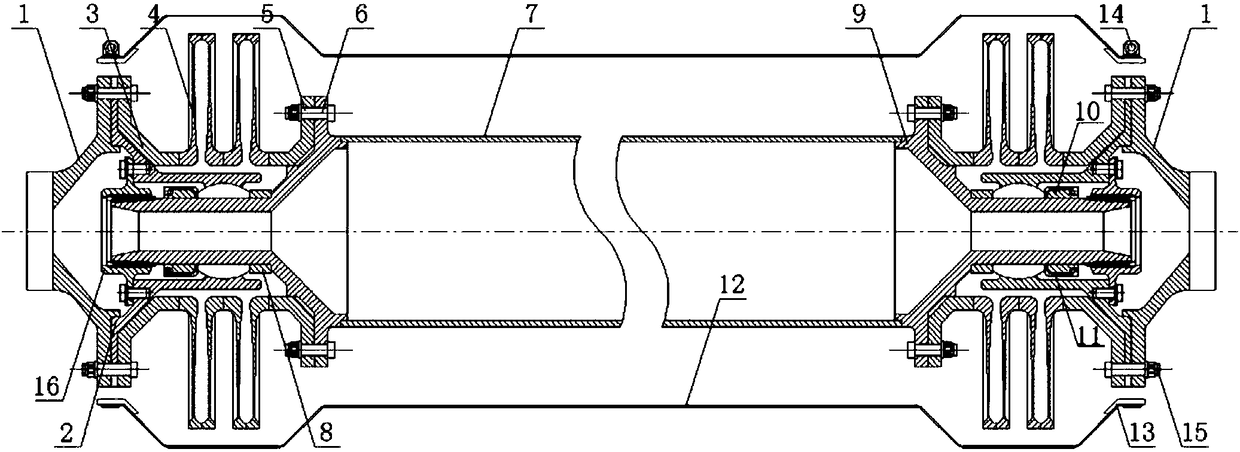

[0026] Please refer to the attached image 3 , in the present invention, the integrated joint bearing (2) can adopt a self-lubricating joint bearing, the outer installation shaft (16) is fitted with the integrated joint bearing (2), and the inner shaft (9) and the spacer shaft (7 ) Welded as one structure, can realize the same function. The spacer shaft (7) is made of carbon fiber composite material, and then bonded to the inner shaft (9), and other components are made of light titanium alloy (except for joint bearings), which can further reduce the critical speed of the rotor and can take into account the long distance power transfer requirements.

Embodiment approach 3

[0028] Please refer to the attached Figure 4, in the present invention, the integrated spherical plain bearing (2) is changed to a split structure of spherical plain bearing plus mounting seat, and the axial positioning is carried out through the spacer sleeve (17) and the collar 18, while realizing the same function, Reduce the manufacturing cost of spherical plain bearings.

[0029] The above-mentioned embodiments disclose three preferred embodiments of a diaphragm coupling with overload protection of the present invention, but the present invention is not limited to the above-mentioned embodiments, and further improvements can be made on the basis of the disclosures in the above-mentioned embodiments and optimization. Attached if possible figure 1 The flange (3) and the inner shaft (9) in the middle are made into an integrated structure, which makes the structure simpler. will attach image 3 , attached Figure 4 The connection mode of the composite spacer shaft and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com