Infrared thermal wave non-destructive detection method

A non-destructive testing and infrared thermal wave technology, which is applied in the direction of material defect testing, etc., can solve problems such as being easily affected by subjective and objective conditions, difficult to save flaw detection results, and difficult flaw detection technology, so that the equipment is harmless to the human body and the equipment is simple. Lightweight and fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

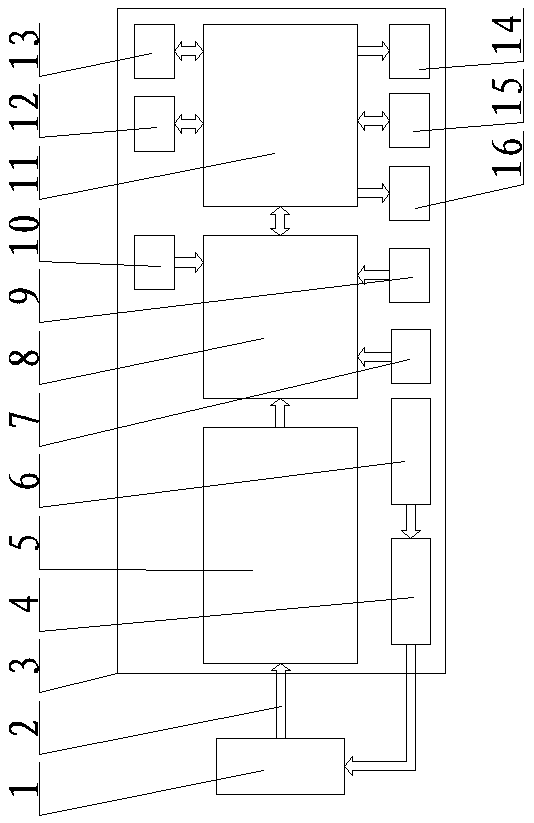

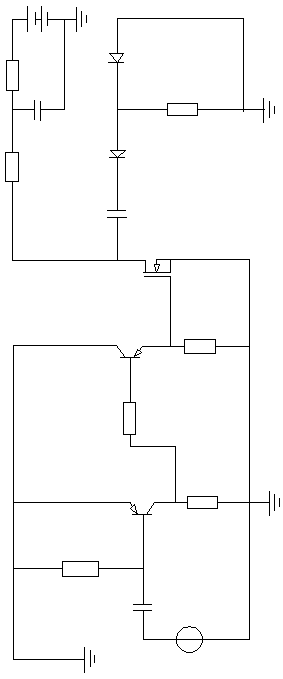

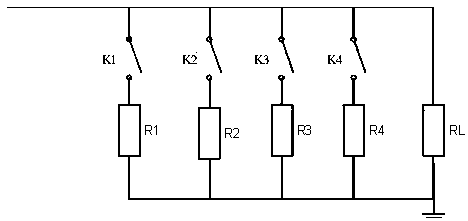

[0024] Infrared thermal wave non-destructive testing method, non-destructive detection of the size, shape and distribution of material surface and internal defects (such as cracks, bubbles, slag inclusions, etc.) The hardware design of the system's ultrasonic flaw detection system provides a wealth of peripheral equipment interfaces, and proposes and realizes the FPGA design of modules such as non-coherent digital envelope detection, positive and negative delay control, and hardware real-time alarm. A three-stage cascaded analog front-end design of controllable gain op amps is proposed and implemented, which meets the requirements of broadband, high gain, high dynamic range and high sampling frequency. A DC / DC converter and The power solution combined with the low dropout (LDO) voltage regulator improves the conversion efficiency of the power supply and enhances the stability of the whole system.

Embodiment 2

[0026] In the infrared thermal wave non-destructive testing method described in Embodiment 1, the housing 3 has a high-speed data acquisition circuit 5, an FPGA preprocessing circuit 8 and an ARM post-processing circuit 11, and the housing 3 also has a power supply 6 and a high voltage generator. 4. The high-speed data acquisition circuit is electrically connected to the FPGA pre-processing circuit, the FPGA pre-processing circuit is electrically connected to the ARM post-processing circuit, and the power supply provides electric energy for all electrical systems in the housing. The described The high-speed data acquisition circuit and the high-voltage generator are respectively connected to the probe 1 located outside the housing through wires 2 .

[0027] Example 2:

[0028] In the infrared heat wave nondestructive testing method described in embodiment 1, the described FPGA preprocessing circuit is also connected with a clock management system 7, a system reset device 9 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com