Linear electromagnetic wave plasma source and plasma processing apparatus employing same

A plasma source and plasma technology, applied in the direction of plasma, circuit, discharge tube, etc., can solve the problems of the reduction of electromagnetic wave intensity and efficiency, and the inability to uniformly maintain the electromagnetic wave intensity of electromagnetic waves, so as to reduce attenuation, realize cooling effect, increase The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

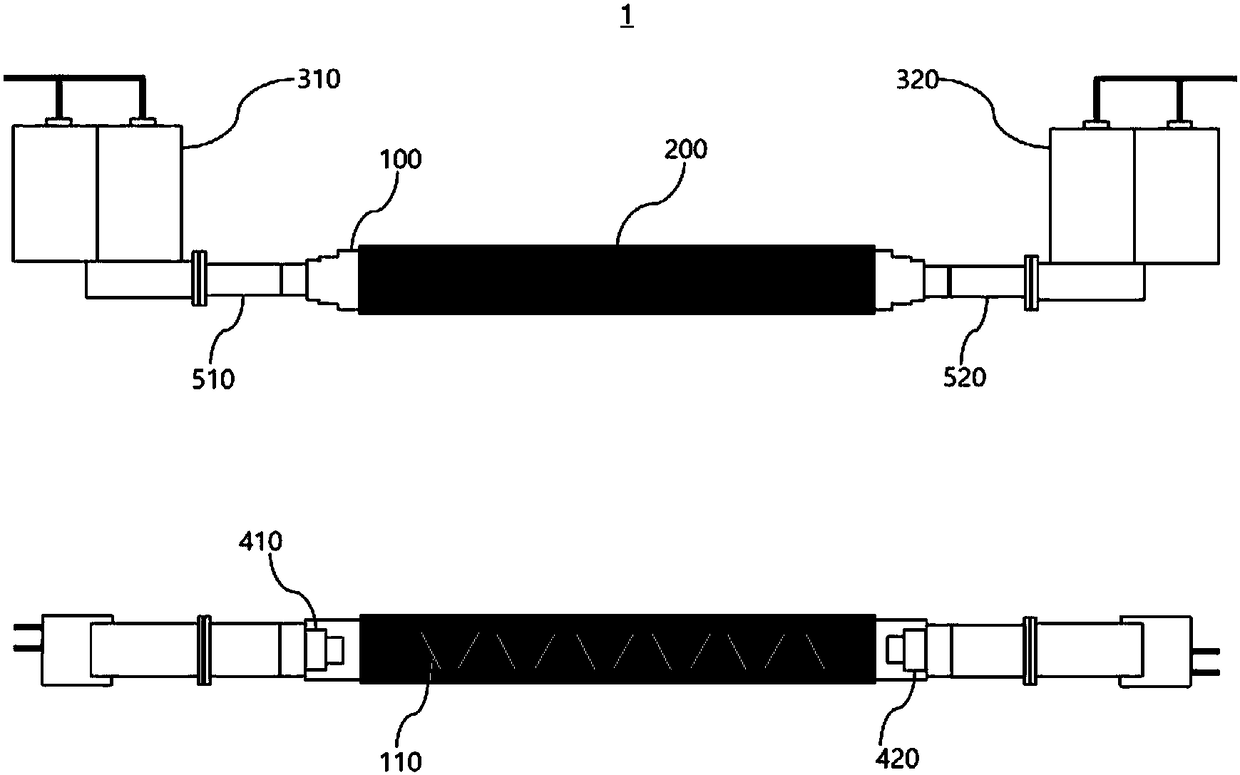

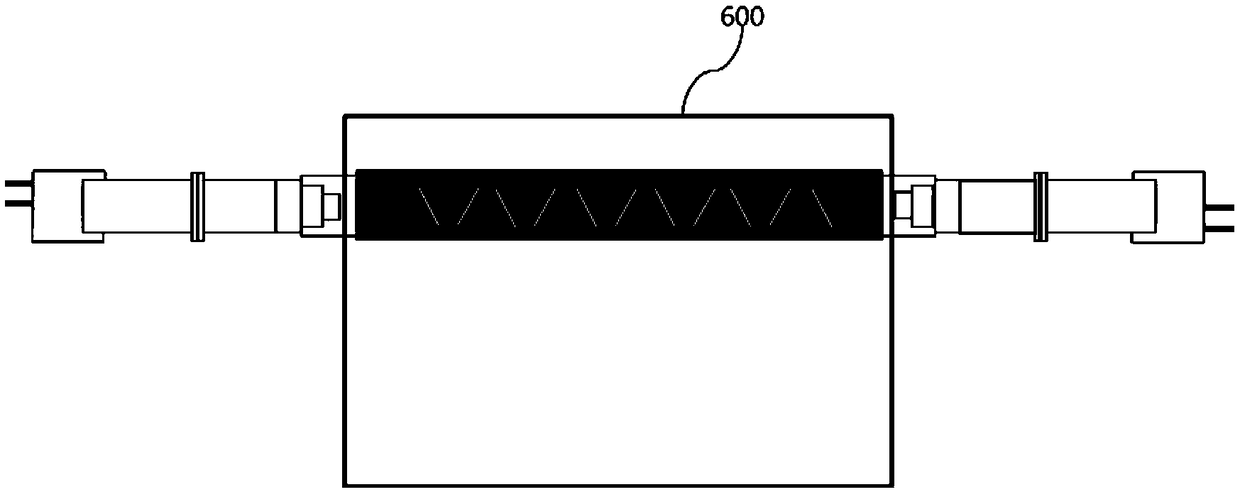

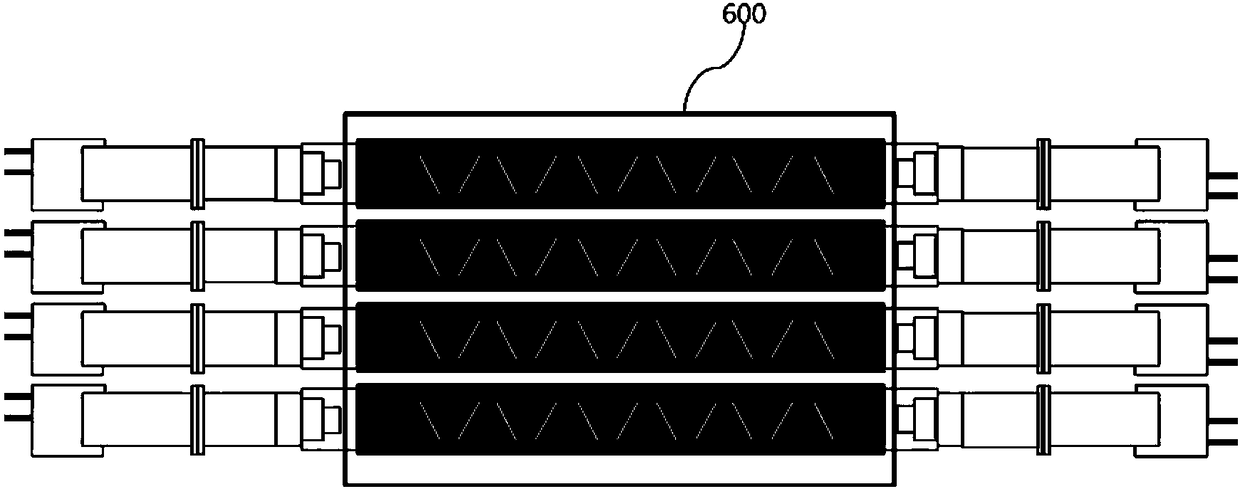

[0030] Detailed matters related to the above-mentioned purpose and technical configuration of the present invention and their accompanying effects can be more clearly understood from the following detailed description based on the accompanying drawings of the specification of the present invention. However, this does not limit the present invention to a specific disclosed form, and it should be understood that all changes, equivalent technical solutions, and replacement technical solutions are included in the idea and technical scope of the present invention. In describing the respective drawings, similar reference numerals are assigned to similar structural elements.

[0031] The terms used in this specification are for describing specific embodiments only, and do not limit the present invention. Expressions in the singular include subordinate expressions unless the context clearly indicates otherwise. It should be understood that throughout the specification, terms such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com