Automatic Welding System

A technology of automatic welding and welding station, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as leak repair, achieve good welding effect, reduce manual analysis, and save labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

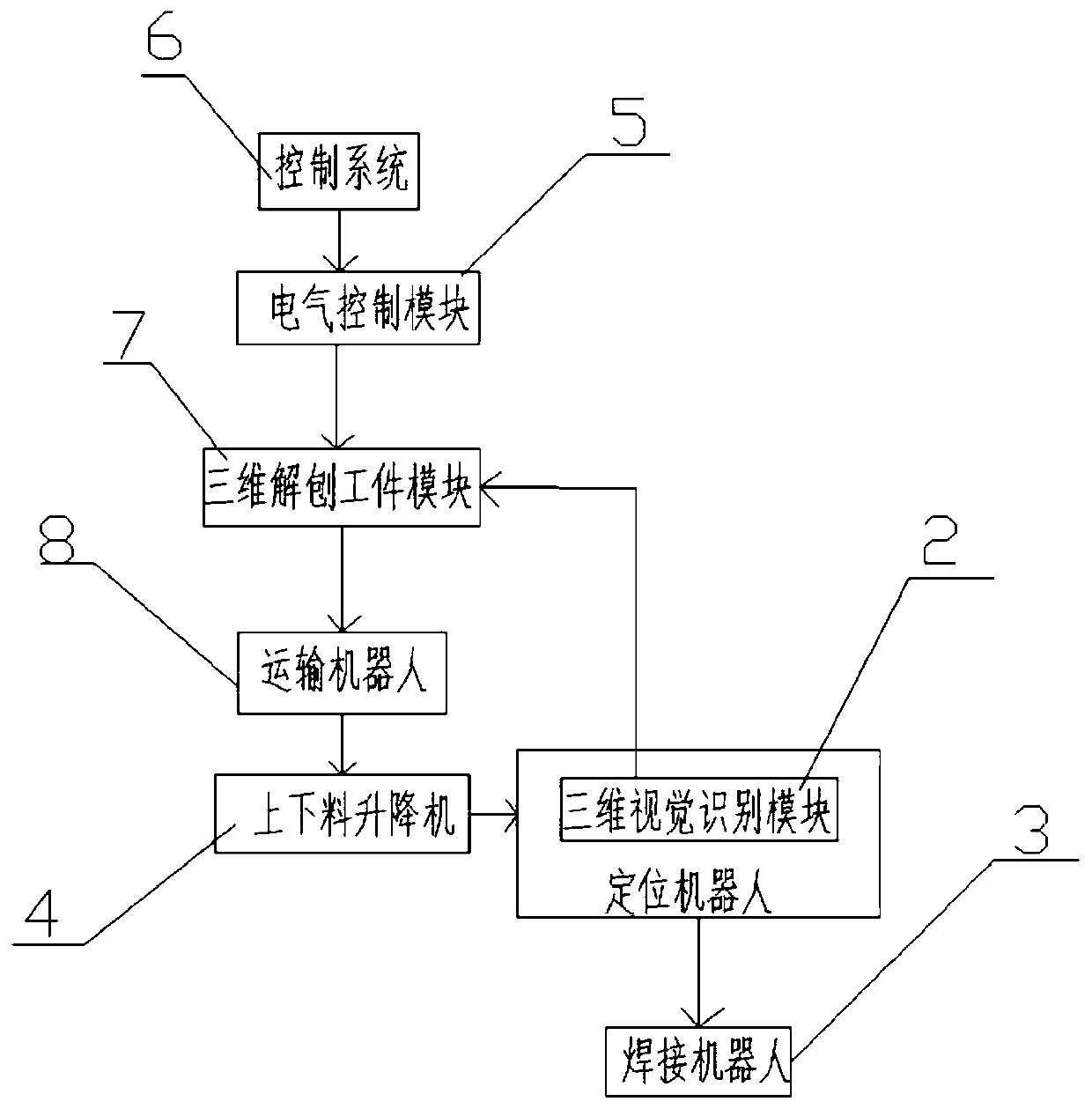

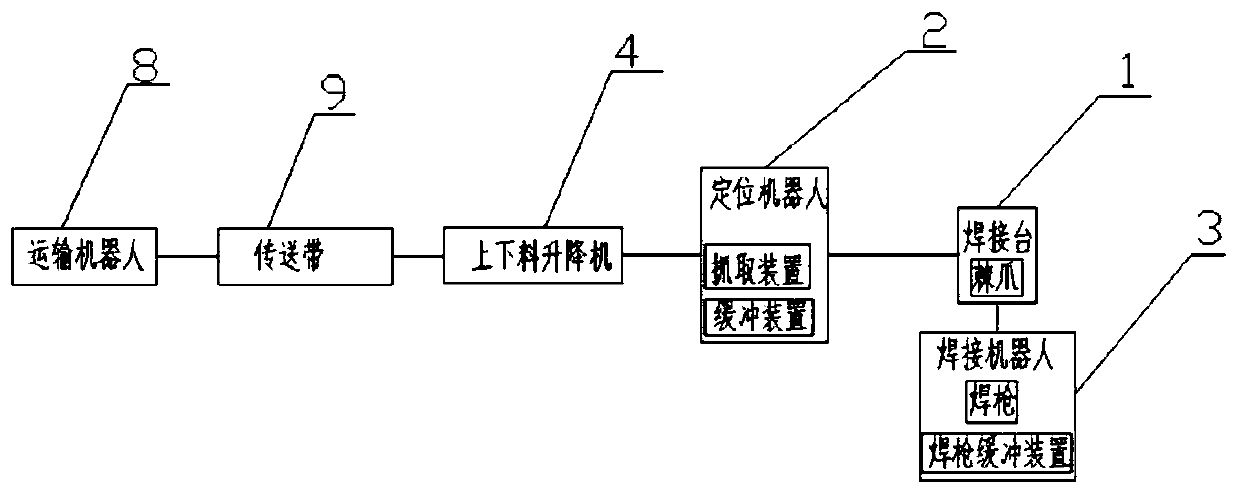

[0011] The automatic welding system of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0012] Such as figure 1 , 2 As shown, the automatic welding system includes a welding table 1 for fixing the welding workpiece, a positioning robot 2 for clamping and grabbing the welding workpiece, a welding robot 3, a loading or unloading elevator 4, an electrical control module 5, a control system 6, and a three-dimensional solution The planing workpiece module 7 and the transport robot 8, the positioning robot 2 for clamping and grabbing the welding workpiece is provided with a three-dimensional visual recognition module, which is connected with the three-dimensional planing workpiece module 7, and grabs and places the buffer device, automatically from Identify and select workpieces to be welded in the loading or unloading elevator 4. The welding robot 3 is provided with a welding torch, a welding torch buff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com