Dendrobium officinale humic acid water-soluble fertilizer, and raw materials and preparation method thereof

A technology for raw materials and humification, which is applied in the field of Dendrobium officinale humic acid water-soluble fertilizer and its raw materials and preparation fields, can solve the problems of inability to effectively increase the yield and polysaccharide content of Dendrobium officinale, incomplete nutrient elements, and great harm to Cordyceps sinensis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

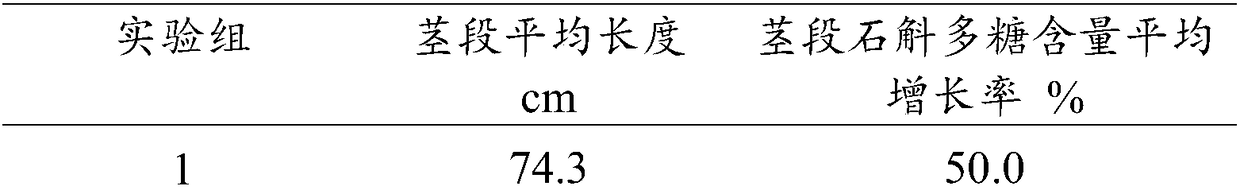

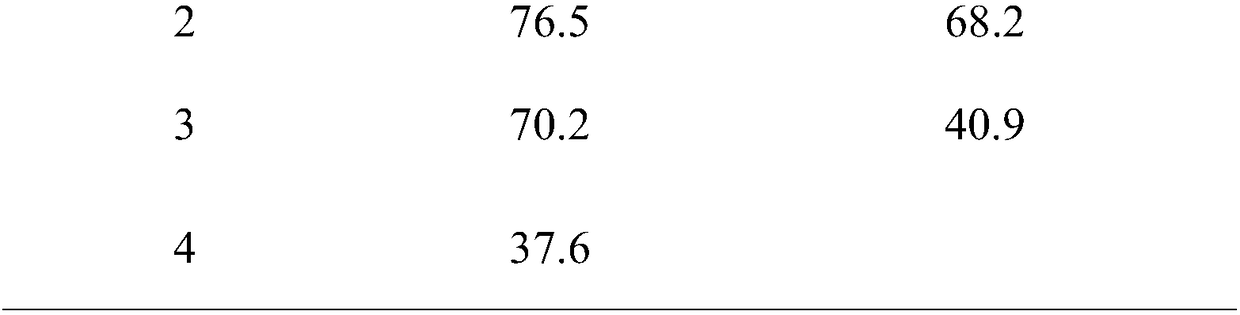

Examples

Embodiment 1

[0024] Weigh 22g of calcium dihydrogen phosphate, 9g of potassium nitrate, 32g of urea and 7g of magnesium sulfate, pulverize them, pass through a 60-mesh sieve, and mix to obtain the first product 1.

[0025] Weigh 1 g of sodium iron EDTA, 1 g of sodium manganese EDTA, 0.04 g of sodium copper EDTA, 0.3 g of sodium zinc EDTA, 0.007 g of sodium molybdate dihydrate, and 0.04 g of boric acid. g, 0.007 g of cobalt chloride and 0.01 g of polyglutamic acid were pulverized and passed through an 80-mesh sieve, and mixed to obtain the second product 1.

[0026] 70g of the first product 1, 2.404g of the second product 1 and 22g of humic acid were mixed, dried, and passed through a 60-mesh sieve to obtain the product 1. Wherein, the moisture content of product 1 is less than 5%.

Embodiment 2

[0028] Weigh 20 g of calcium dihydrogen phosphate, 8.8 g of potassium nitrate, 30.4 g of urea and 6 g of magnesium sulfate, pulverize them, pass through a 60-mesh sieve, and mix to obtain the first product 2.

[0029] Weigh 0.9g sodium iron EDTA, 0.9g sodium manganese EDTA, 0.02g sodium copper EDTA, 0.11g sodium zinc EDTA, 0.005g sodium molybdate dihydrate, 0.03 g of boric acid, 0.005 g of cobalt chloride and 0.01 g of polyglutamic acid were pulverized, passed through a 60-mesh sieve, and mixed to obtain the second product 2.

[0030] 65.2g of the first product 2, 1.98g of the second product 2 and 32.5g of fulvic acid were mixed, dried, and passed through a 60-mesh sieve to obtain the product 2. Wherein, the moisture content of product 2 is less than 5%.

Embodiment 3

[0032] Weigh 18g of calcium dihydrogen phosphate, 7g of potassium nitrate, 28g of urea and 5g of magnesium sulfate, pulverize them, pass through a 60-mesh sieve, and mix to obtain the first product 3.

[0033] Weigh 0.8g sodium iron EDTA, 0.8g sodium manganese EDTA, 0.01g sodium copper EDTA, 0.1g sodium zinc EDTA, 0.003g sodium molybdate dihydrate, 0.02 g of boric acid, 0.003 g of cobalt chloride and 0.005 g of polyglutamic acid were pulverized and passed through an 80-mesh sieve, and mixed to obtain the second product 3.

[0034] 58g of the first product 3, 1.741g of the second product 3 and 42g of sodium humate were mixed, dried, and passed through a 60-mesh sieve to obtain the product 3. Wherein, the moisture content of product 3 is less than 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com