A kind of electroplating grade pc/abs alloy material and preparation method thereof

An alloy material, electroplating grade technology, applied in electroplating grade PC/ABS alloy material and its preparation, electroplating grade PC/ABS alloy product and its preparation field, can solve the problem of damage to material strength, low yield rate, and defects on the surface after plating and other problems, to achieve the effect of improving chemical resistance, high electroplating adhesion, and good electroplating adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

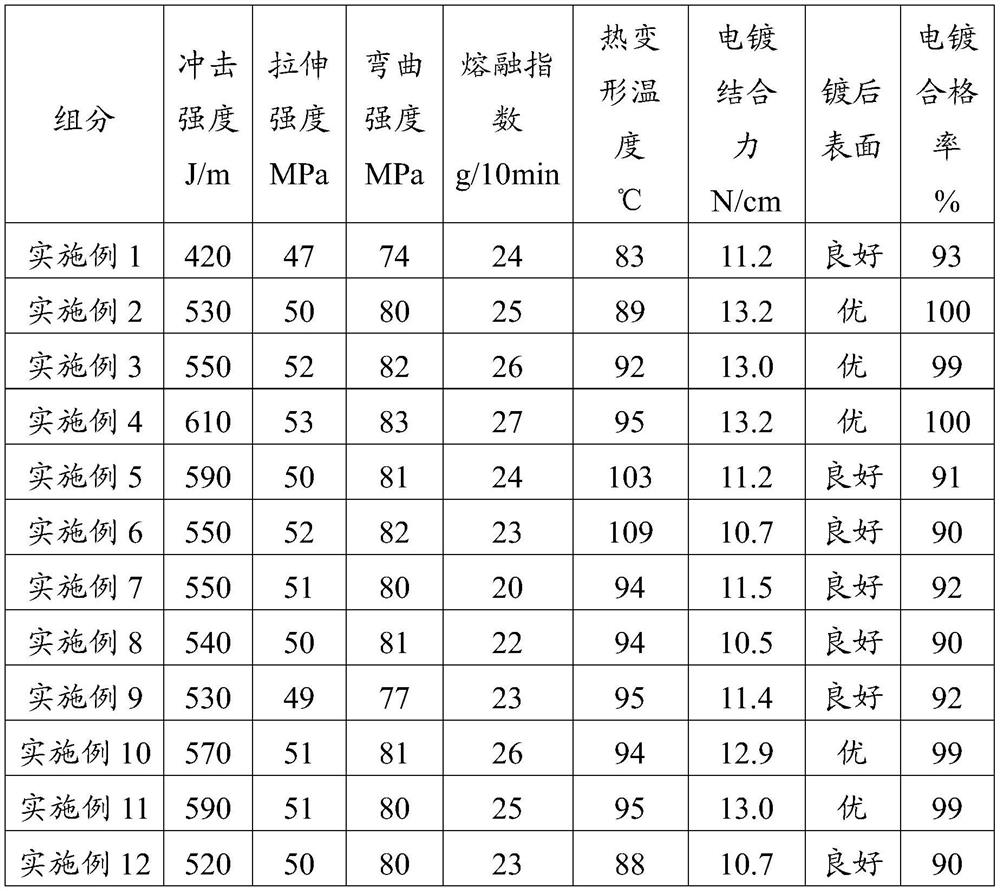

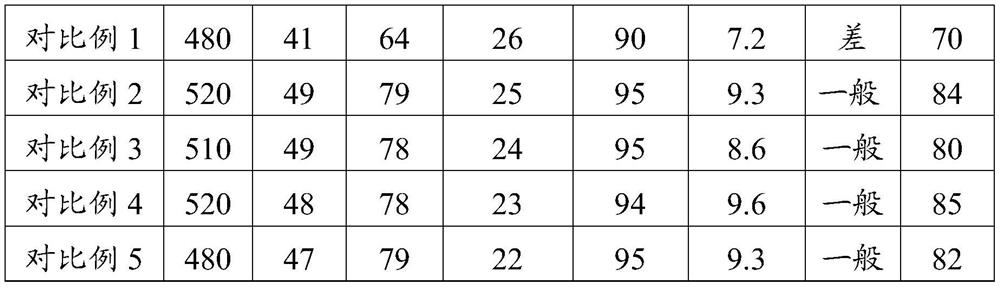

Examples

Embodiment 1

[0048] It includes the following raw materials by weight: PC-1: 10 parts, ABS-1: 70 parts, carboxyl-terminated nitrile rubber 20 parts, antioxidant 0.3 part, lubricant 0.4 part. The material composition is added into a high-speed mixer for mixing, then added into a twin-screw extruder, extruded and granulated, and the temperature in the processing temperature zone is controlled at 200-240°C. After the granulation is completed, dry at 70-90°C for 3-4 hours to fully remove moisture, control the injection mold temperature at 60-90°C, barrel temperature at 220-250°C, injection speed at 30-70mm / s, and injection pressure at 30-70bar. An electroplating grade PC / ABS alloy injection molded product of 140×90×3 mm was obtained.

Embodiment 2

[0050] It includes the following raw materials by weight: PC-1: 30 parts, ABS-1: 45 parts, carboxyl-terminated nitrile rubber 25 parts, antioxidant 0.3 part, lubricant 0.4 part. The material composition is added into a high-speed mixer for mixing, then added into a twin-screw extruder, extruded and granulated, and the temperature in the processing temperature zone is controlled at 200-240°C. After the granulation is completed, dry at 70-90°C for 3-4 hours to fully remove moisture, control the injection mold temperature at 60-90°C, barrel temperature at 220-250°C, injection speed at 30-70mm / s, and injection pressure at 30-70bar. An electroplating grade PC / ABS alloy injection molded product of 140×90×3 mm was obtained.

Embodiment 3

[0052] It includes the following raw materials by weight: PC-1: 40 parts, ABS-1: 35 parts, carboxy-terminated nitrile rubber 25 parts, antioxidant 0.3 part, lubricant 0.4 part. The material composition is added into a high-speed mixer for mixing, then added into a twin-screw extruder, extruded and granulated, and the temperature in the processing temperature zone is controlled at 200-240°C. After the granulation is completed, dry at 70-90°C for 3-4 hours to fully remove moisture, control the injection mold temperature at 60-90°C, barrel temperature at 220-250°C, injection speed at 30-70mm / s, and injection pressure at 30-70bar. An electroplating grade PC / ABS alloy injection molded product of 140×90×3 mm was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com