Deep foundation pit deformation distribution type monitoring system based on OFDR technology

A distributed monitoring and deep foundation pit technology, applied in the field of foundation soil survey, foundation structure test, foundation structure engineering, etc., can solve the problems of low survival rate of measurement points, inability to achieve real-time monitoring, limited data collection, etc. , to achieve high sensitivity and spatial resolution, lower engineering monitoring costs, and low R&D and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

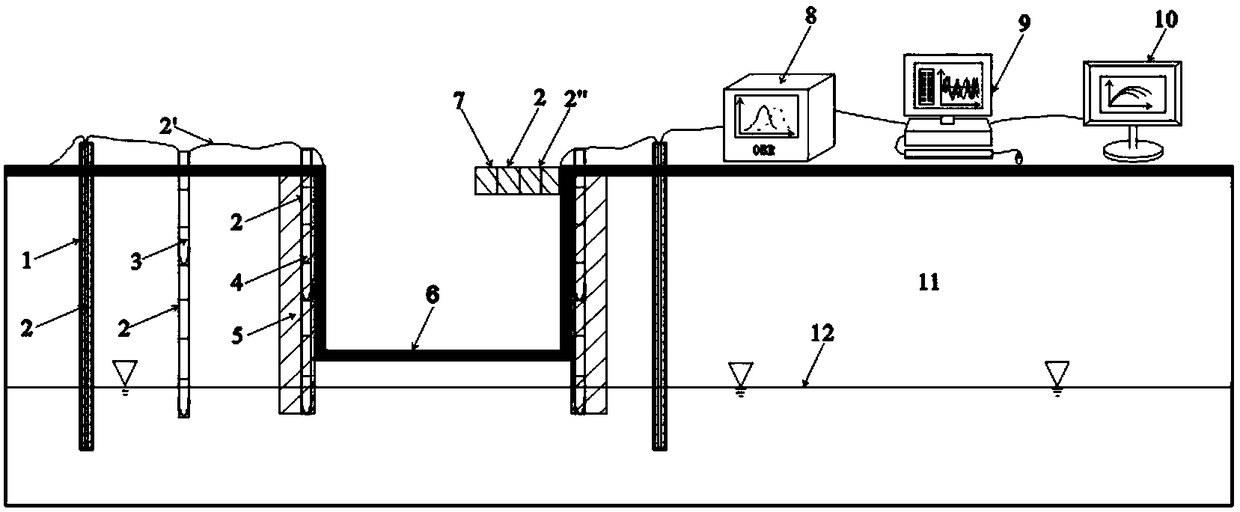

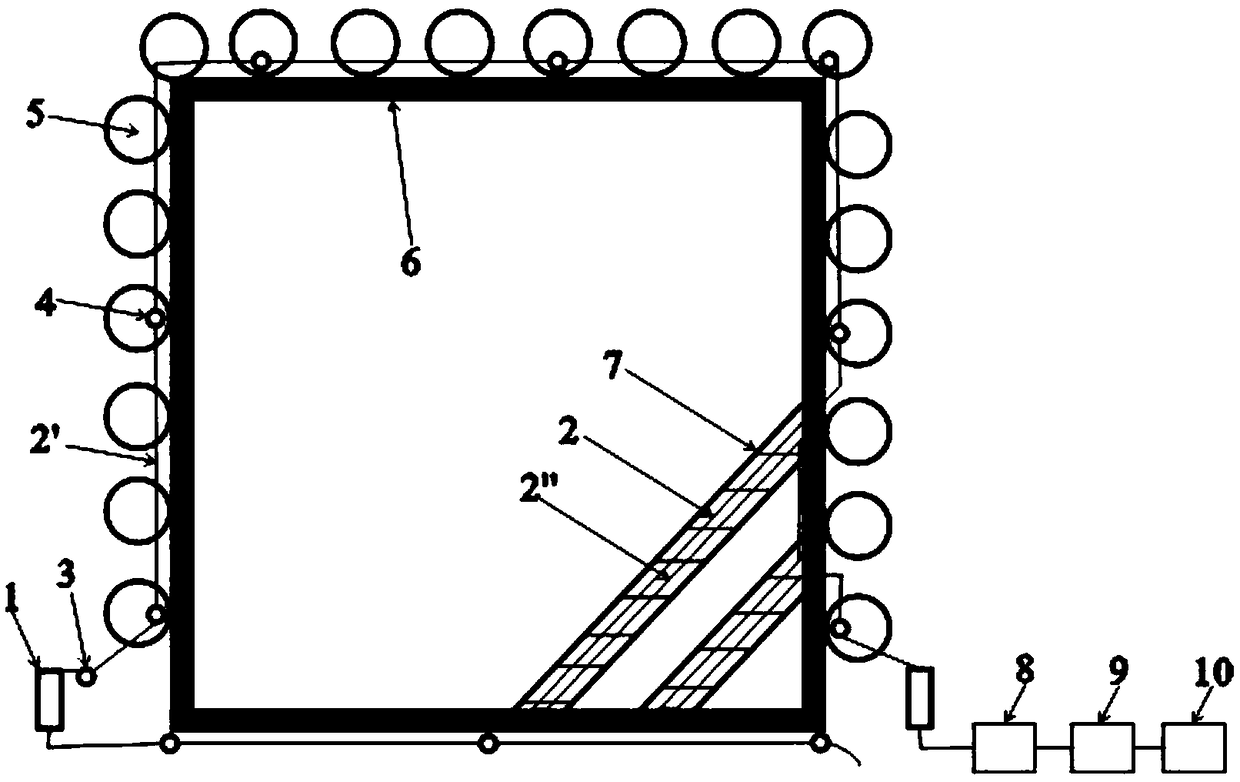

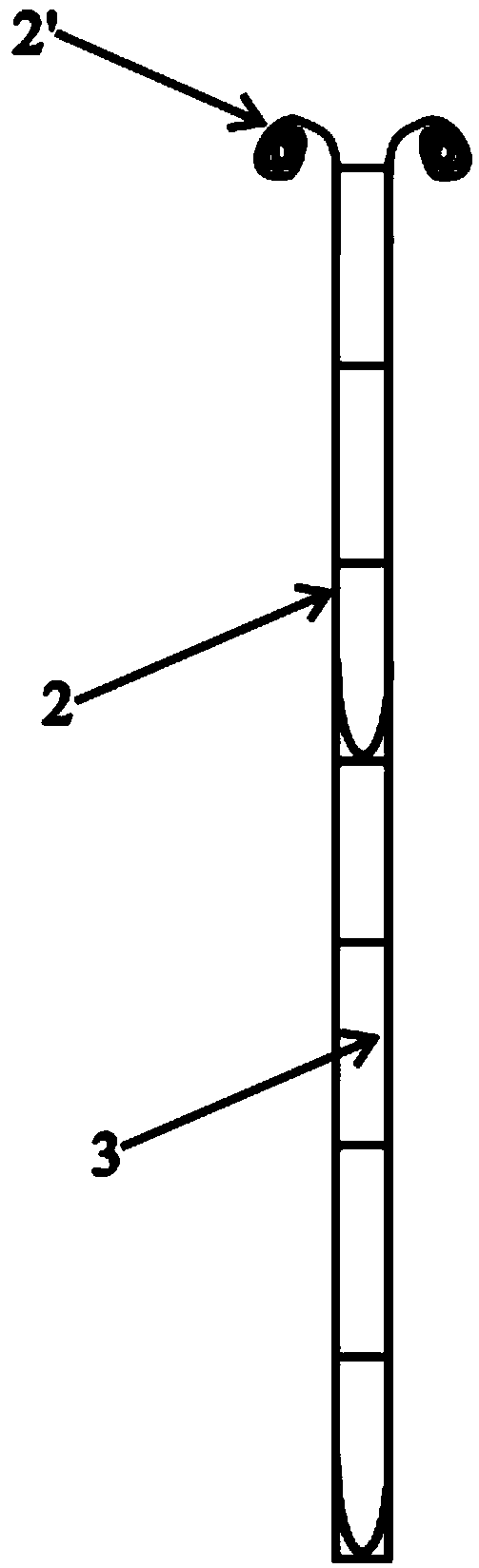

[0031] The overall cross-sectional schematic diagram of this embodiment is as figure 1 as shown, figure 1 Among them, 1 is a distributed optical fiber water level gauge, and the details are as follows Figure 4 As shown, the optical fiber is placed in the groove in the middle of the tape in a small U shape. The depth of the groove is 1.5mm. There are scales on both ends of the tape. Meet different engineering needs. The end of the optical fiber is aligned with the bottom of the scale, and the optical fiber is arranged in a U shape. On the one hand, the monitoring data on the left and right sides can be obtained in one measurement, and the average value of the two can reduce the measurement error. On the other hand, the U-shaped arrangement enables the water level gauge to Connect with adjacent optical fibers to facilitate the formation of a monitoring network. 2 is PE optical fiber, which is directly sealed into the groove of the soft ruler with adhesive during laying, with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com