OBR-based prefabricated pile body stress-strain monitoring system and using method

A stress-strain monitoring system technology, applied in the direction of force measurement, measurement force, measurement device, etc. by measuring the change of optical properties of materials when they are stressed, can solve the problem of complex fabrication process, high price, spatial resolution and poor quality of FBG sensors. The problem of low monitoring accuracy is to achieve the effect of reducing engineering monitoring costs, low R&D and manufacturing costs, and realizing automatic processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

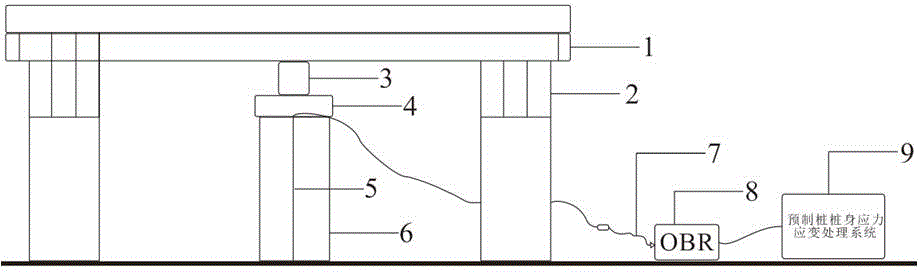

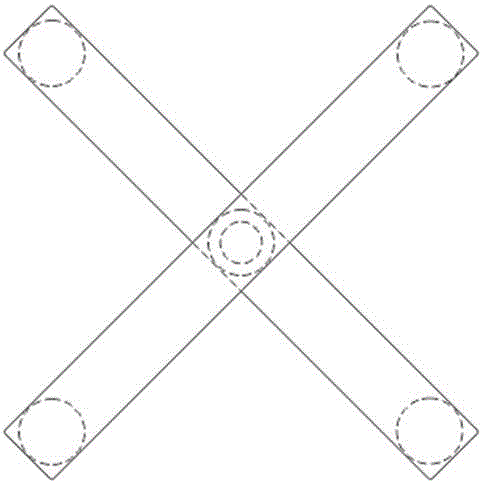

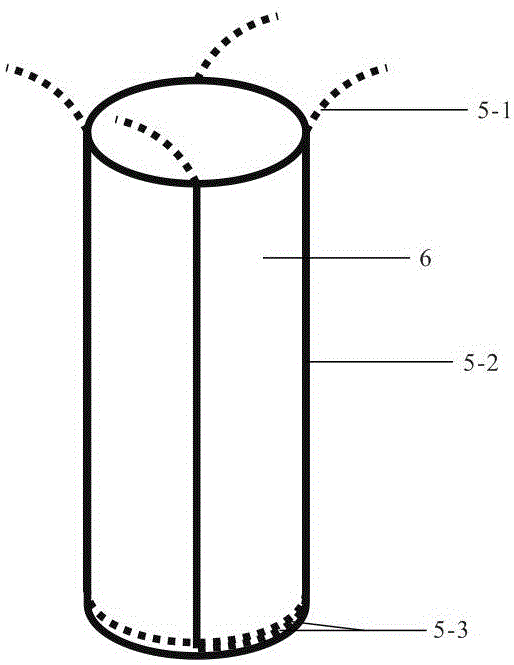

[0035] The overall structure schematic diagram of this embodiment is as follows figure 1 As shown, the entire monitoring system is divided into three modules, the loading and applying module, the optical fiber laying module, and the acquisition and processing module. 1 is an I-shaped rigid beam, 2 is a steel bar connecting the steel plate and the surrounding pile, and the connection method is welding, and 3 is a jack. 4 is rigid backing plate, and size is suitable with pile diameter. 5 is an optical fiber, using PE optical fiber, 6 is a test pile, and 7 is an optical fiber jumper, which is used to connect the optical fiber to be tested with the OBR data acquisition instrument, and the optical fiber to be tested is fused with an optical fiber fusion splicer. 8 is an OBR data acquisition instrument, including an optical fiber data acquisition system and an optical fiber signal data acquisition system, and 9 is a prefabricated pile body stress and strain processing system.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com