Face structure light scanning apparatus

A scanning device and surface structured light technology, applied in the field of measuring instruments, can solve the problems of slow measurement speed, inability to measure black objects and reflective objects, cumbersome operation, etc., and achieve convenient installation and unloading, stable and compact structure, and large measurement area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below according to the accompanying drawings and examples.

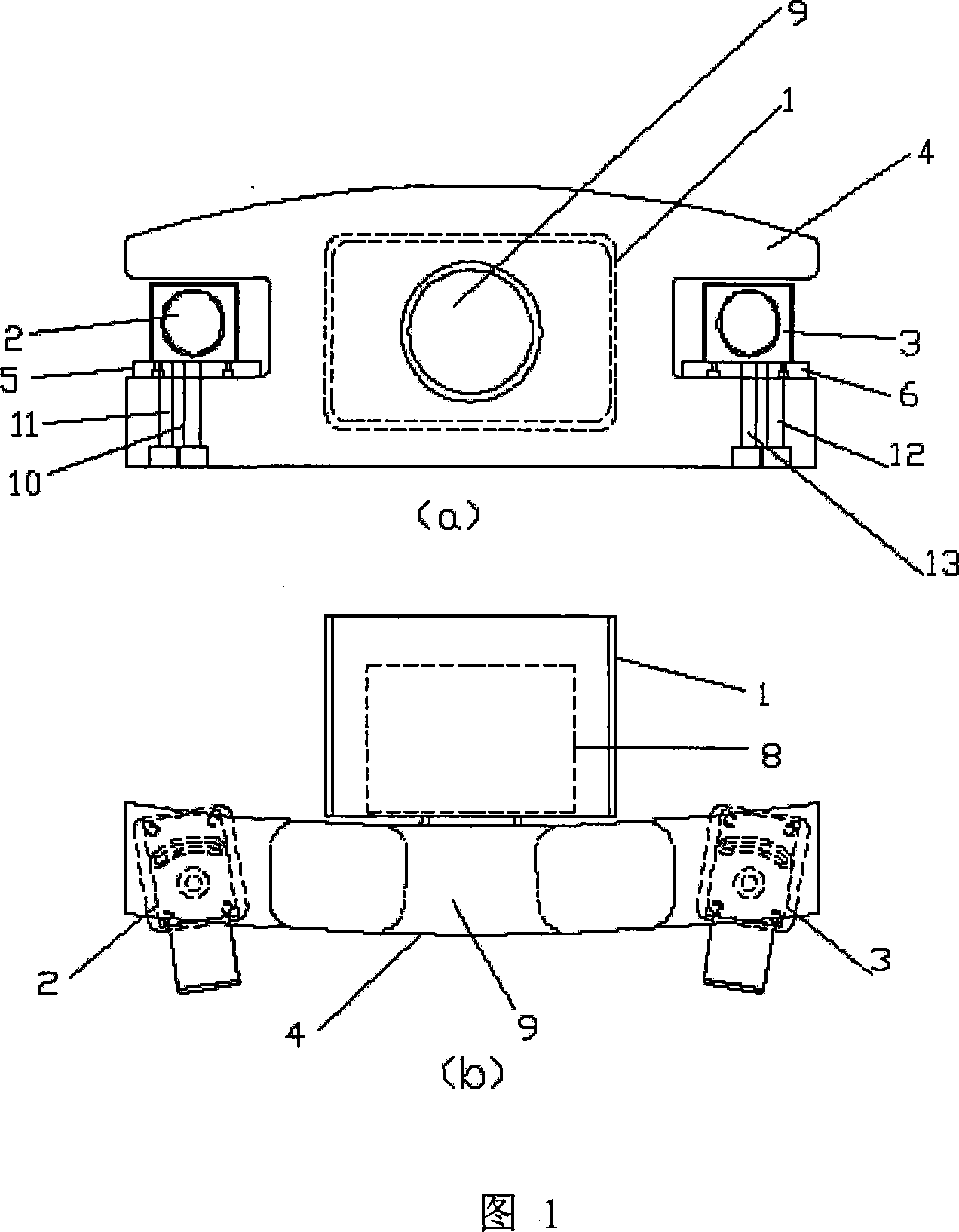

[0014] As shown in FIG. 1 , the surface structured light scanning device of the present invention includes a left CCD camera 2 , a right CCD camera 3 and a projector 8 .

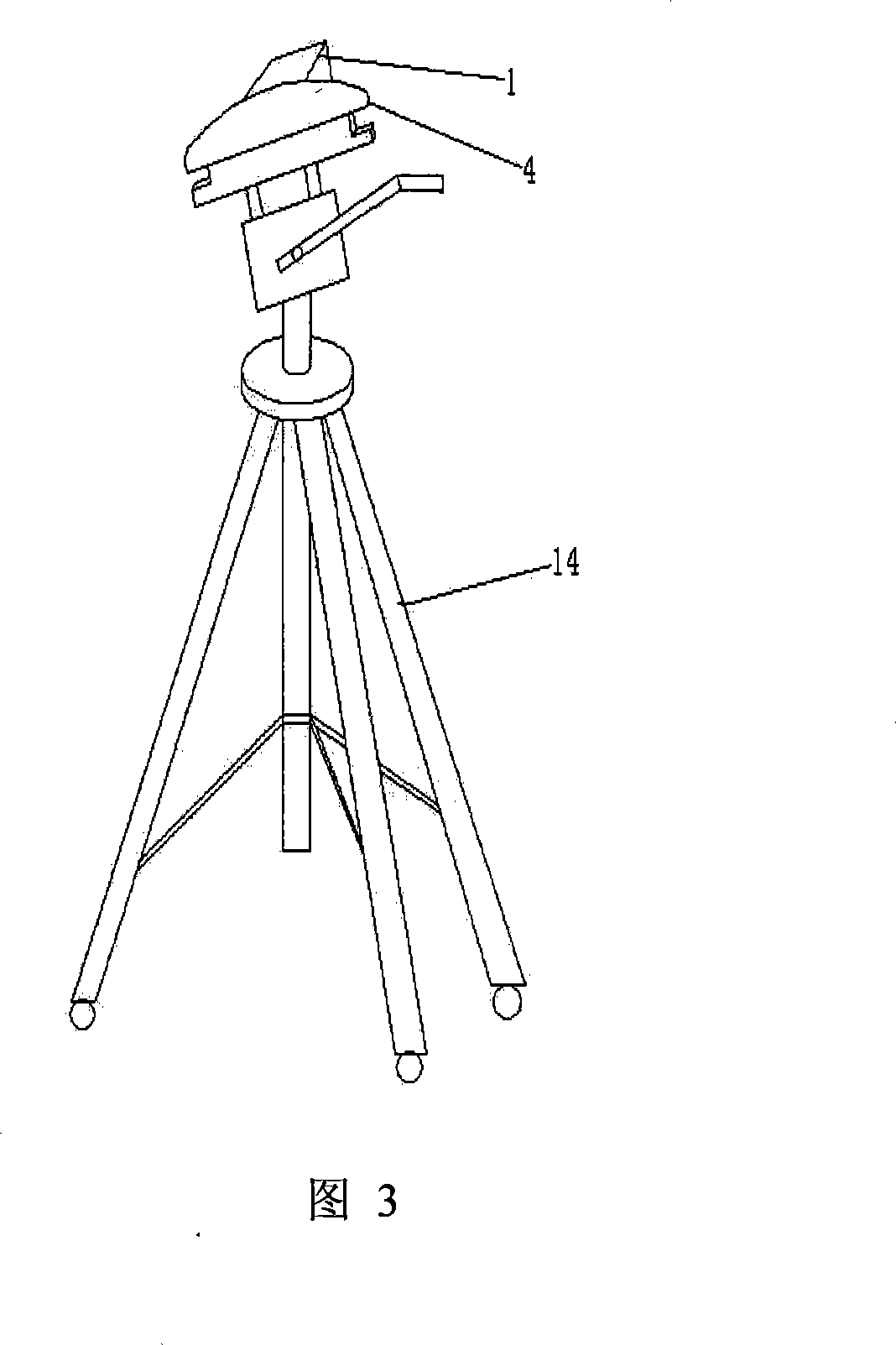

[0015] The frame 1 adopts a hollow structure, the projector 14 is located in the frame 1 , and the bottom of the frame 1 is connected with the tripod 14 .

[0016] The two ends of the mounting frame 4 are provided with through grooves, the left and right sides through grooves are of symmetrical structure, and the middle part is provided with a through hole 9 .

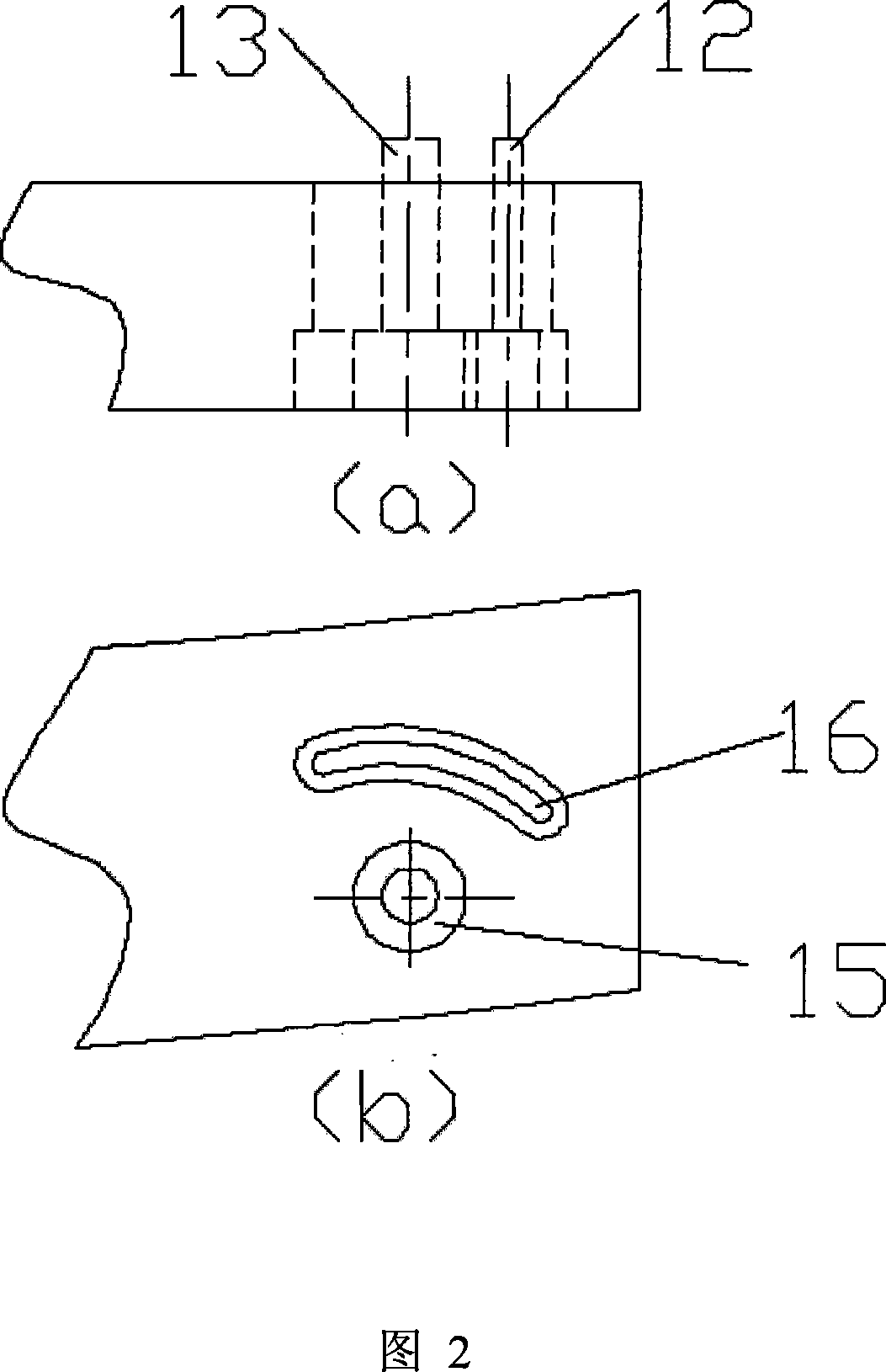

[0017] The left CCD camera head 2 is fixedly connected with the left fixed block 5, and is installed in the left through groove of the mounting frame 4 by first and second screws 10,11. The right CCD camera head 3 is fixedly connected with the right fixed block 6, and is installed in the right through groove of the installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com