A self-lubricating gear with micro-texture

A micro-textured, self-lubricating technology, applied to components with teeth, belts/chains/gears, gear lubrication/cooling, etc., can solve problems such as difficult lubrication film, gear damage, and reduced service life of gears. Friction, reduce friction and wear of tooth surface, and reduce consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

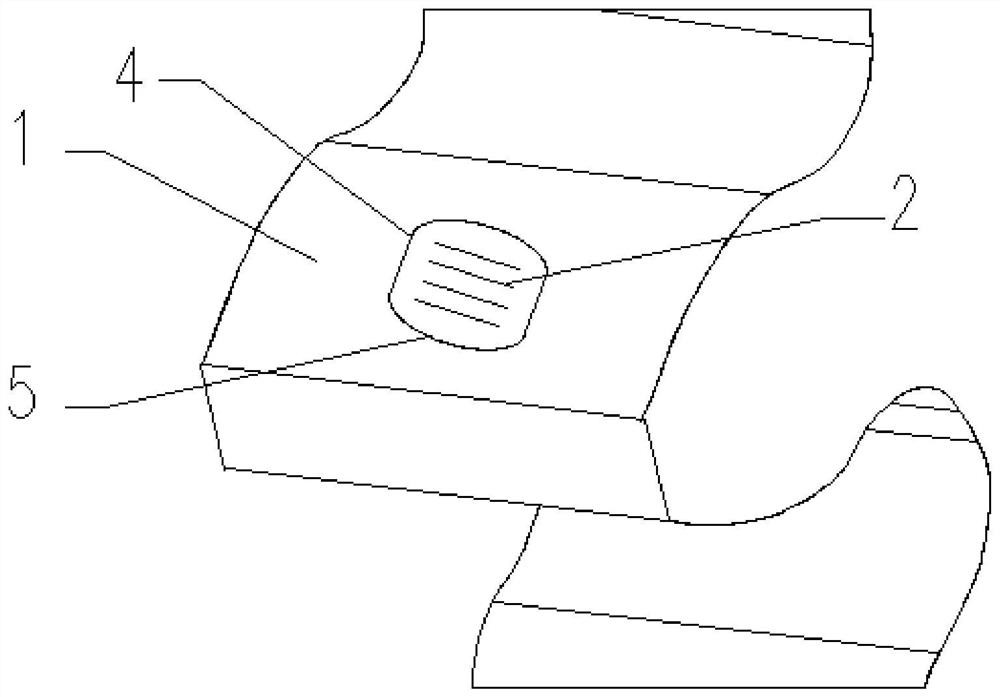

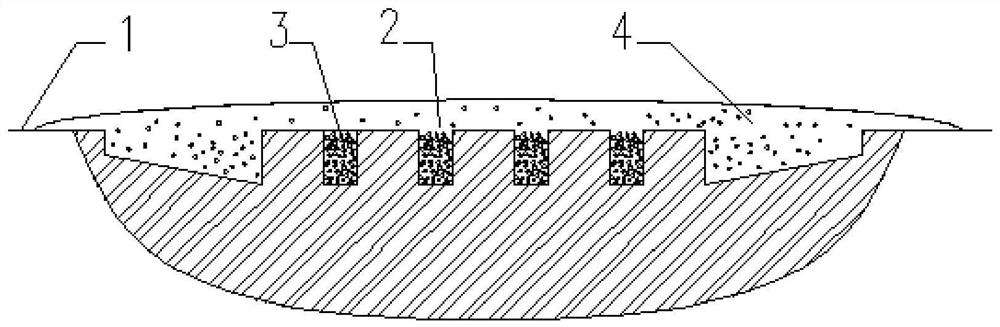

[0023] Such as figure 1 and figure 2 A self-lubricating gear with a micro-texture is shown, the micro-texture includes an array of transverse grooves arranged on the gear meshing tooth surface 1, and the array of transverse grooves includes transverse grooves 2 arranged in parallel, And the depth direction of the transverse groove 2 is perpendicular to the meshing tooth surface 1, the transverse groove 2 is also filled with lubricating medium 3, and the micro-texture also includes the meshing tooth surface 1 provided on the periphery of the transverse groove array. An outer groove 4 with a closed edge, and the edge 5 of the outer groove 4 perpendicular to the friction direction of the meshing tooth surface 1 is an arc edge, and the bottom surface of the outer groove 4 is a slope inclined to the transverse groove 2 Surface; the width of the outer groove 4 is between 15-30 μm, and the width of the lateral groove 2 is between 10-15 μm.

[0024] In this example, there are four ...

Embodiment 2

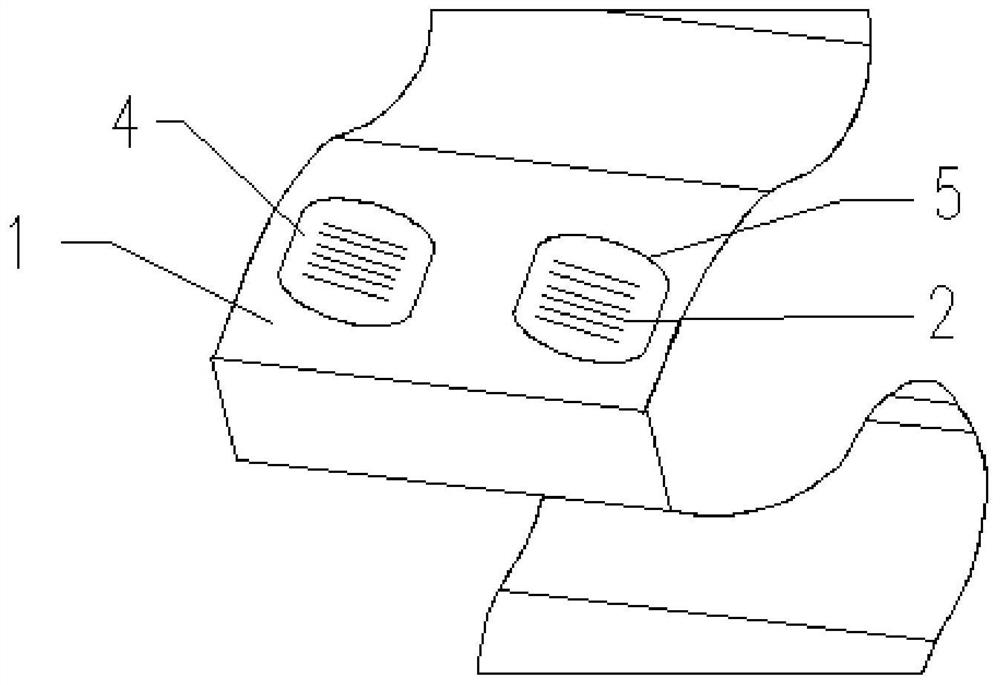

[0027] Such as image 3 A self-lubricating gear with a micro-texture is shown, the micro-texture includes an array of transverse grooves arranged on the tooth surface 1 of the gear, and the array of transverse grooves includes two pairs of transverse grooves arranged in parallel 2, and the depth direction of the transverse groove 2 is perpendicular to the meshing tooth surface 1, and the interior of the transverse groove 2 is also filled with a lubricating medium 3, and the micro-texture also includes that the meshing tooth surface 1 is arranged on the periphery of the transverse groove array Some have an outer groove 4 with a closed edge, and the edge 5 of the outer groove 4 perpendicular to the friction direction of the meshing tooth surface 1 is an arc edge, and the bottom surface of the outer groove 4 is inclined to the transverse groove 2 slope.

[0028] In this example, the outer groove 4 has a width of 15 μm, and the lateral groove 2 has a width of 10 μm.

[0029] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com