Optical imaging lens unit

An optical imaging lens and imaging technology, applied in optics, optical components, instruments, etc., can solve the problems of heavy optical imaging lens, long distance, unfavorable thinning of portable electronic products, etc., to maintain imaging quality, reduce lens length, expand The effect of field of view and aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

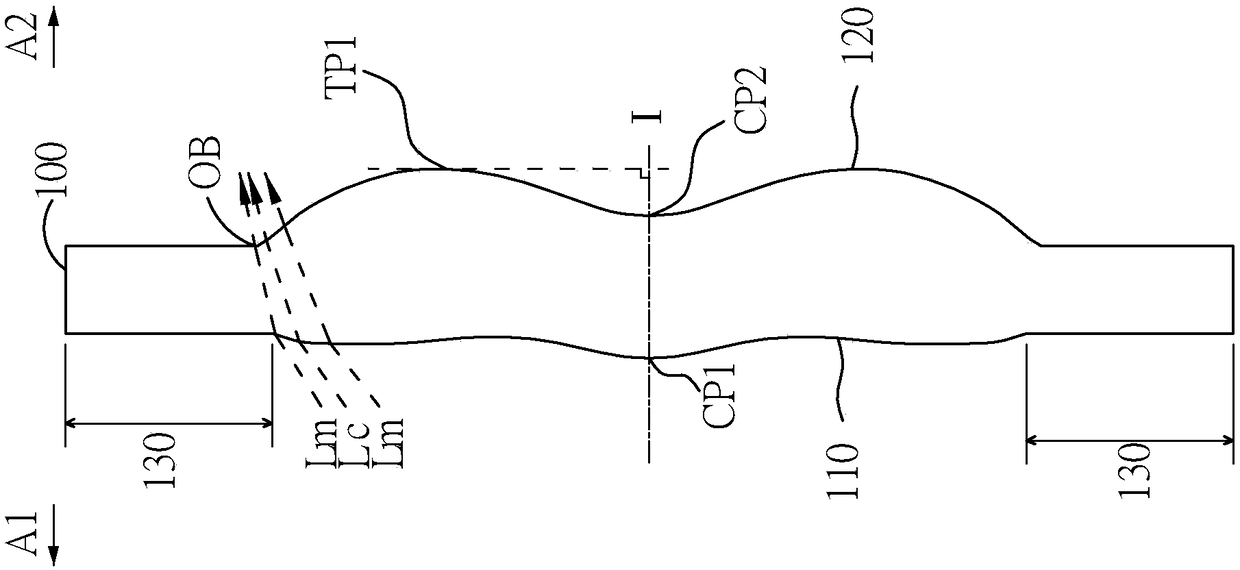

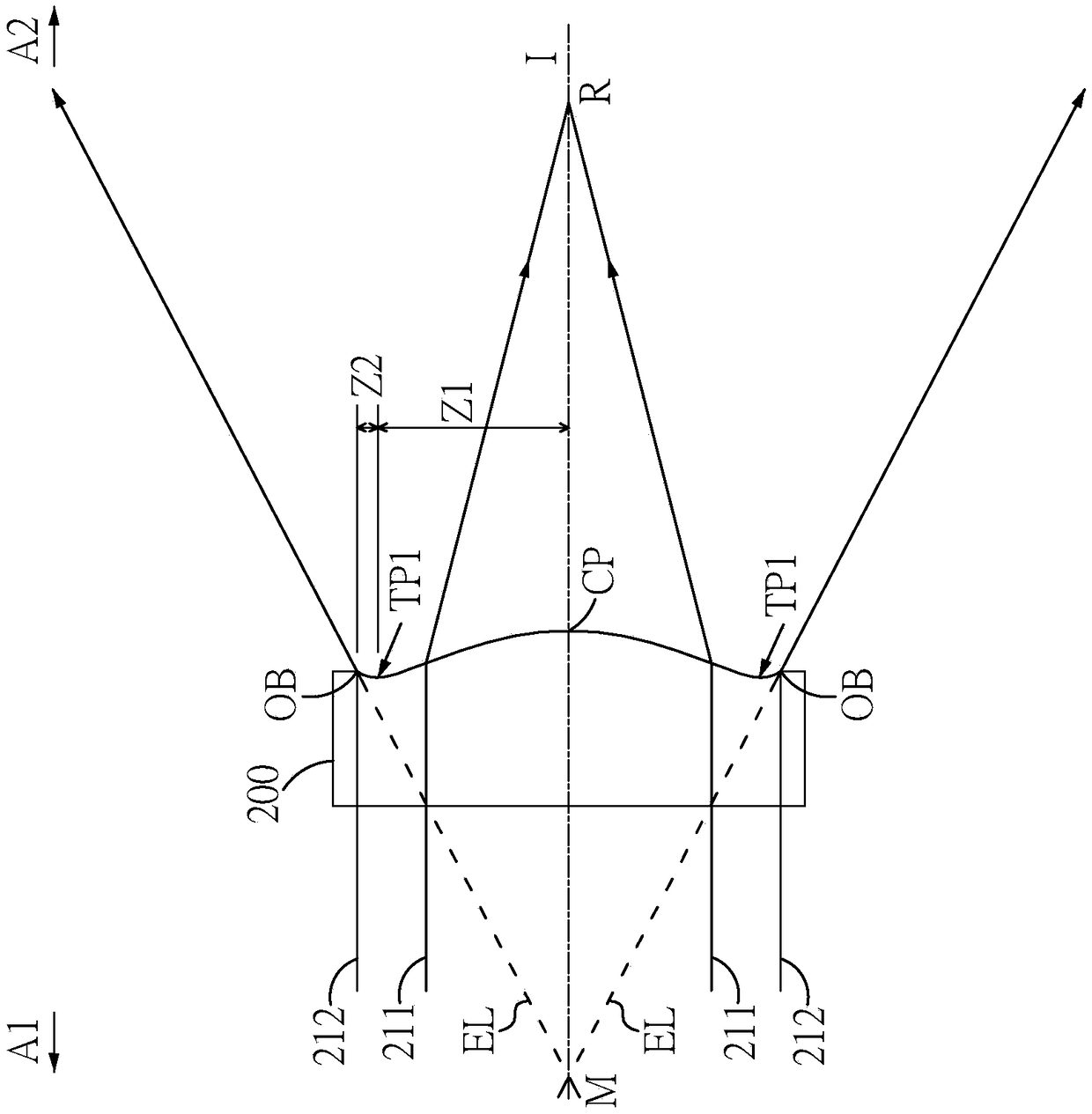

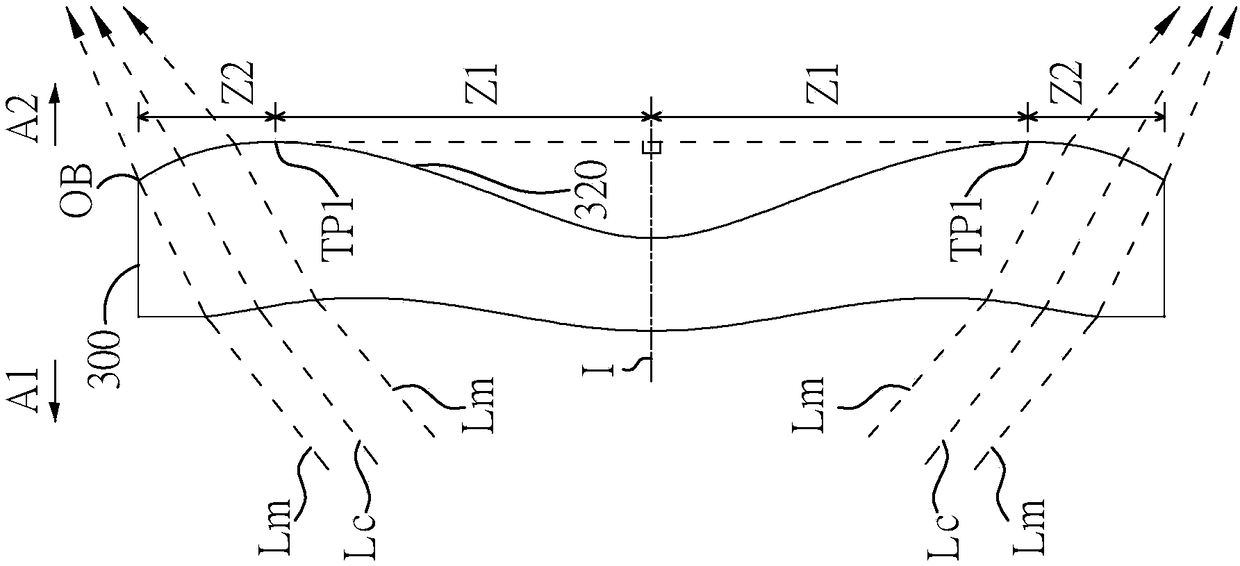

[0086] Before starting to describe the present invention in detail, first clearly represent the symbolic explanation in the accompanying drawings:

[0087]1,2,3,4,5,6,7,8,9,10,11,12 optical imaging lens; 100,200,300,400,500 lens; 100',200',300',400',500',600,700,800,900,1000,11 '00,12'00光圈;110',210,310,410',510',610,710,810,910,1010,11'10,12'10第一透镜;110,111,121,131,141,151,161,171,181,191,211',221,231,241,251,261,271,281,291,311,321,331,341,351,361,371,381,391,410,411,421,431,441,451,461,471,481,491,510,511,521,531,541,551,561,571,581,591,611,621,631,641,651,661,671,681,691,711,721,731,741,751,761,771,781,791,811,821,831,841,851,861,871,881,891,911,921,931,941,951,961,971,981,991,1011,1021,1031,1041,1051,1061,1071 ,1081,1091,11'11,11'21,11'31,11'41,11'51,11'61,11'71,11'81,11'91,12'11,12'21,12 '31,12'41,12'51,12'61,12'71,12'81,12'91物侧面;120,112,122,132,142,152,162,172,182,192,212',222,232,242,252,262,272,282,292,312,320,322,332,342,352,362,372,382,392,412,422,432,442,452,462,472,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com