A high-life composite grid suitable for lead-acid batteries and its preparation method

A technology of lead-acid batteries and composite boards, applied to battery electrodes, circuits, electrolytic coatings, etc., can solve problems such as short life and corrosion resistance, and achieve the effects of improving battery life, prolonging service life, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Electrochemical pretreatment: use the grid as the anode, and the stainless steel sheet as the cathode, immerse in a mixed solution of 0.1mol / L sodium hydroxide and 0.05mol / L sodium phosphate, use constant current mode, and the current density is 3.5Adm -2 , the processing time is 100s.

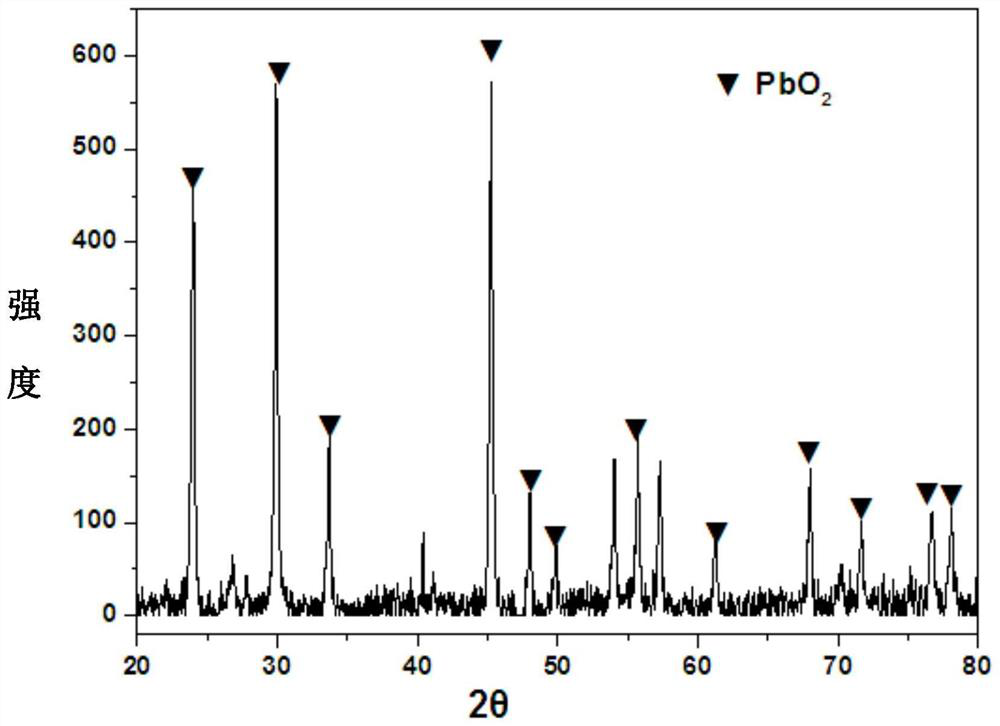

[0030] (2) Micro-arc oxidation: use the grid obtained in the previous step as the anode, and the lead plate as the cathode, and immerse it in a mixed solution of 1.6mol / L sulfuric acid and 0.9mol / L phosphoric acid, and use the composite pulse control method to carry out micro-arc oxidation. Its control parameters are: the positive oxidation termination voltage is 50V, the negative termination voltage is 45V, the oxidation time is 10min, and the current density is 2.5A / dm 2 , the frequency is 300Hz, the positive duty cycle is 30%, and the negative duty cycle is 15%.

[0031] (3) Post-treatment: the grid after the oxidation in the previous step is washed with alkali, washed with wate...

Embodiment 2

[0038] (1) Electrochemical pretreatment: use the grid as the anode and the stainless steel sheet as the cathode, immerse in a mixed solution of 0.2mol / L sodium hydroxide and 0.05mol / L sodium phosphate, use constant current mode, and the current density is 4Adm -2 , the processing time is 80s.

[0039] (2) Micro-arc oxidation: the grid obtained in the previous step is used as the anode, and the lead plate is used as the cathode. In a mixed solution of 1.8mol / L sulfuric acid and 1.1mol / L phosphoric acid, the compound pulse control method is used to carry out micro-arc oxidation. The control parameters are: the positive oxidation termination voltage is 80V, the negative termination voltage is 60V, the oxidation time is 20min, and the current density is 3.7A / dm 2, the frequency is 500Hz, the positive duty cycle is 40%, and the negative duty cycle is 30%.

[0040] (3) Post-treatment: the grid after the oxidation in the previous step is washed with alkali, washed with water to neut...

Embodiment 3

[0044] (1) Electrochemical pretreatment: use the grid as the anode, and the stainless steel sheet as the cathode, immerse in a mixed solution of 0.5mol / L sodium hydroxide and 0.01mol / L sodium phosphate, use constant current mode, and the current density is 5.5Adm -2 , the processing time is 30s.

[0045] (2) Micro-arc oxidation: the grid obtained in the previous step is used as an anode, and the lead plate is used as a cathode. In a mixed solution of 2.0mol / L sulfuric acid and 1.3mol / L phosphoric acid, the composite pulse control method is used to carry out micro-arc oxidation. The control parameters are: the positive oxidation termination voltage is 95V, the negative termination voltage is 75V, the oxidation time is 30min, and the current density is 4.2A / dm 2 , the frequency is 700Hz, the positive duty cycle is 50%, and the negative duty cycle is 30%.

[0046] (3) Post-treatment: the grid after the oxidation in the previous step is washed with alkali, washed with water to ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com