Sterilization machine

A sterilizer and machine trough technology, applied in food preservation, food preparation, food science and other directions, can solve the problems of increased energy consumption and equipment investment, difficult control of final moisture content of materials, low heating uniformity of materials, etc., to improve the temperature Uniform distribution, improved sterilization effect, stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

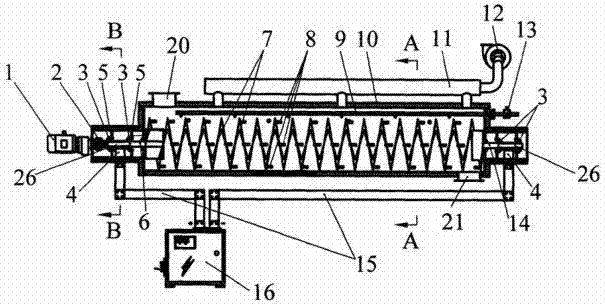

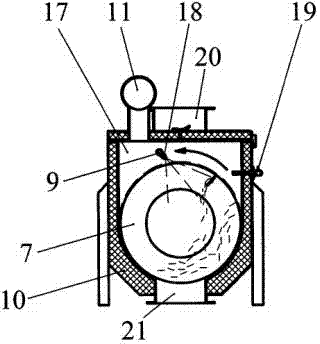

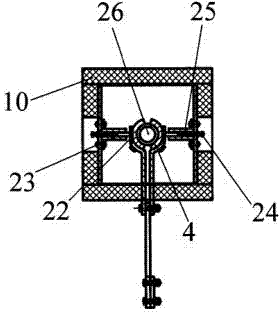

[0030] Such as Figure 1 to Figure 3 As shown, a sterilizer includes a machine tank 17 and a spiral blade 7 located in the machine tank 17, and the machine tank 17 is provided with an inlet 20 and an outlet 21 . A reduction motor 1 is arranged outside the machine slot, and the reduction motor 1 is connected with the left shaft head 6 of the helical blade through a shaft coupling 2 . The left spindle head 6 of spiral blade is arranged on machine groove 17 wallboards by bearing 3, and the right spindle head 14 of spiral blade is also arranged on machine groove 17 wallboards by bearing 3.

[0031] It is also provided with a power supply 16, a conductive plate 15, a contact piece 4 and an insulating plate 5, and the power supply 16 forms an electric circuit with the left and right shaft heads of the spiral blade through the conductive plate 15, the contact piece 4; Connect with machine slot 17 through insulating plate 5.

[0032] The above-mentioned power supply 16 can adopt a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com