Full-automatic cleaning system and cleaning method of photovoltaic module

A photovoltaic module and cleaning system technology, applied in the field of cleaning systems, can solve the problems of large number of photovoltaic factory areas, shading, and wasteful use of cleaning robots, and achieve the effects of real-time unmanned cleaning, reduced pressure unevenness, and strong ability to overcome obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

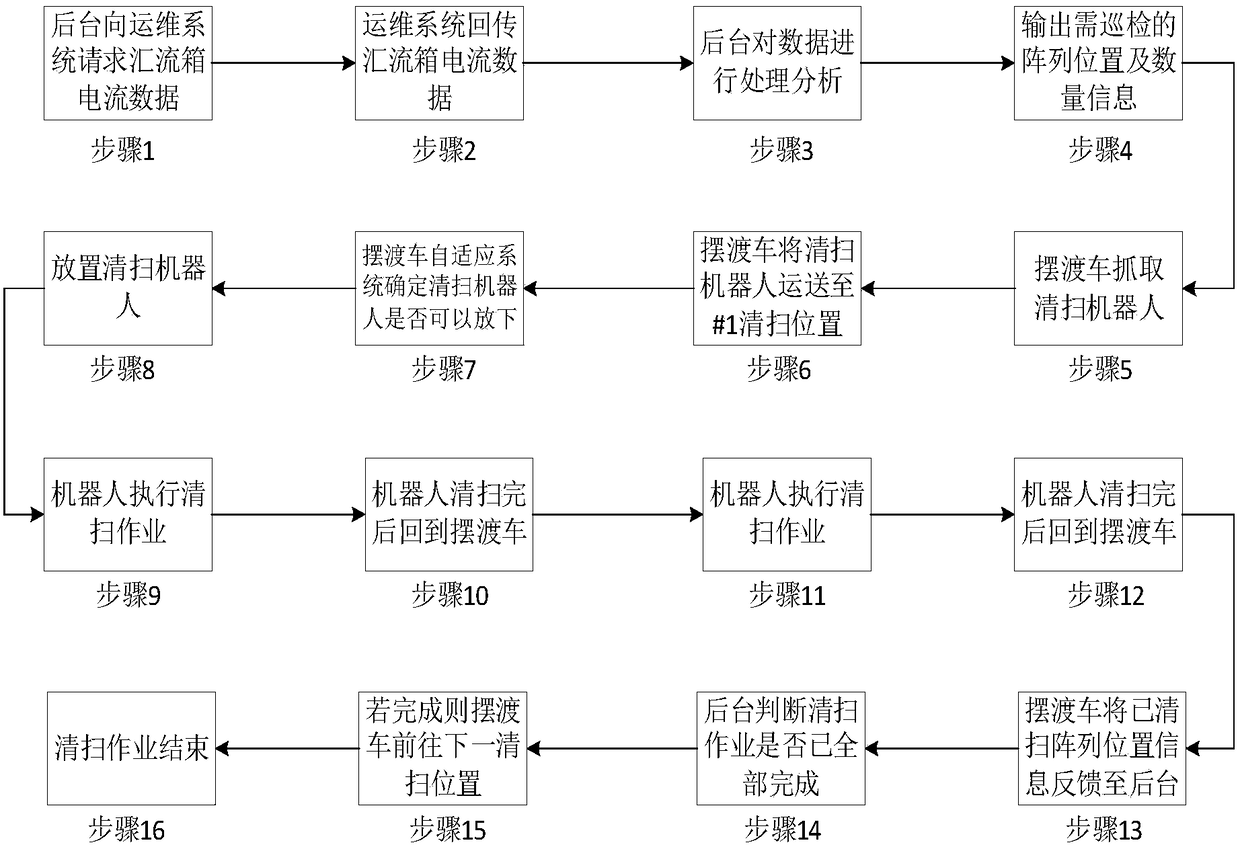

[0034] The present invention will be further described below in conjunction with specific embodiments. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0035] Below in conjunction with accompanying drawing and embodiment the patent of the present invention is further described.

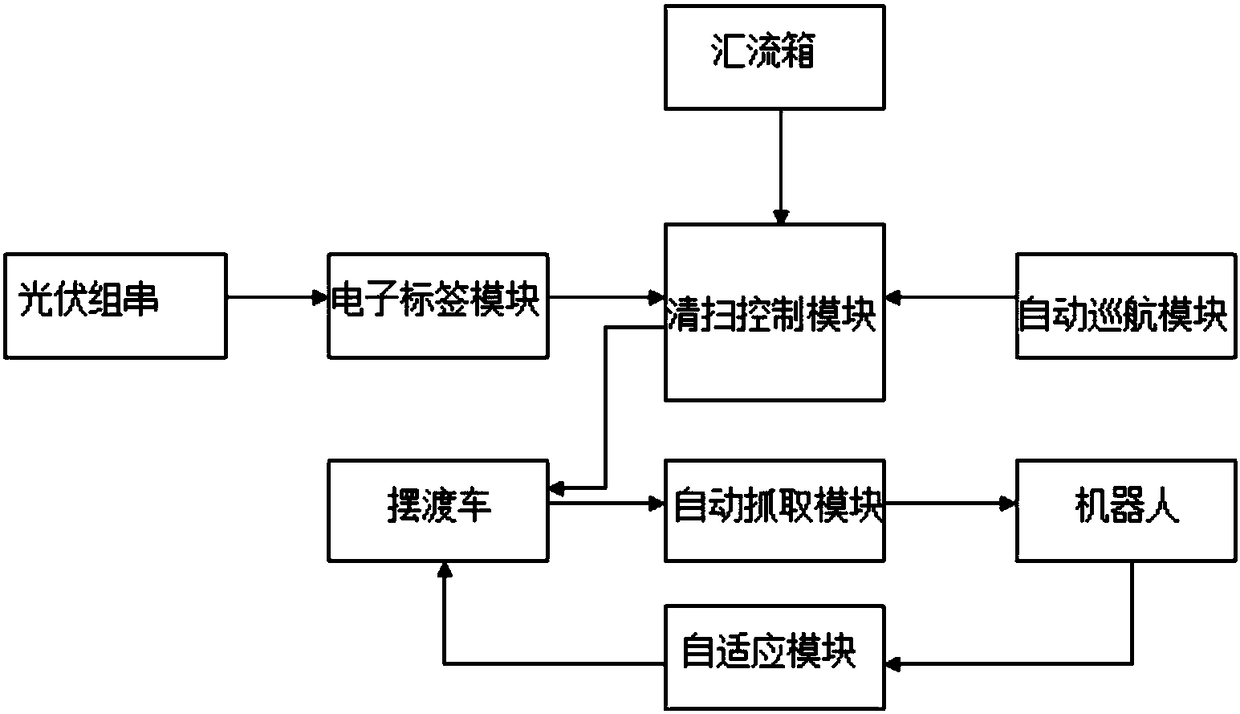

[0036] Such as figure 1 As shown, the present invention provides a fully automatic cleaning system for photovoltaic modules, including a shuttle bus, a robot, an adaptive module, an electronic label module, a cleaning control module and an automatic grabbing module;

[0037] The electronic label module is used to collect the position coordinates of each row and row of photovoltaic strings in the photovoltaic power station, and upload them to the cleaning control module;

[0038] The cleaning control module judges whether the photovoltaic string needs to be cleaned by coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com