Liquefied gas desulphurization alcoholic lye regeneration tail gas deodorizing method

An alcohol-lye and liquefied gas technology, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation to achieve the effect of reducing operating costs and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

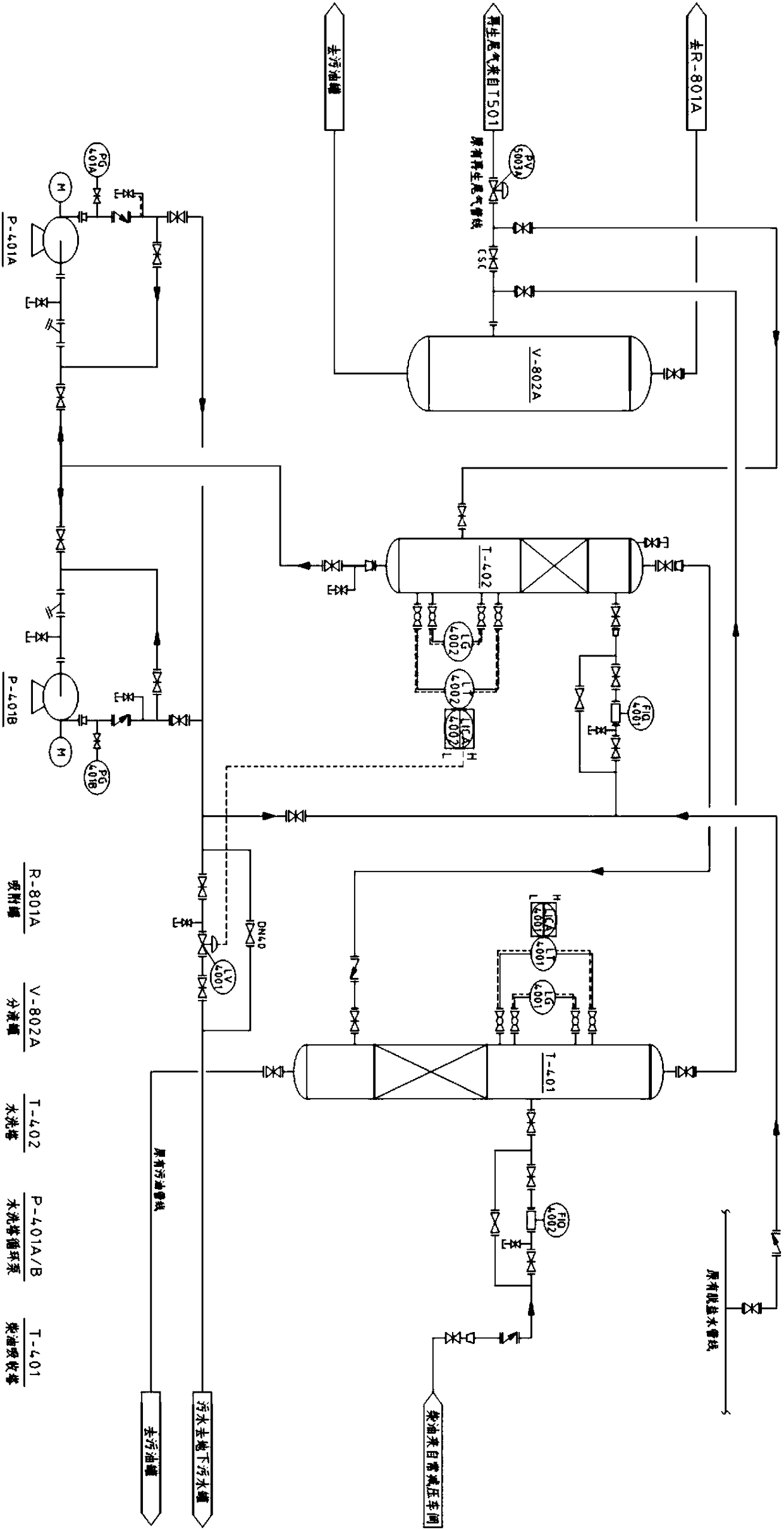

[0017] This embodiment proposes a method for deodorizing tail gas from regeneration of liquefied gas sweetening alkali liquor, and the deodorizing method adopts such as figure 1 Shown technological process, comprises the steps:

[0018] S1. The tail gas regenerated from liquefied gas demercaptan alkali solution enters the bottom of the water washing tower T-402, and countercurrently contacts with the desalted water entering from the top to wash off the residual alkali solution in the tail gas. Two water washing circulation pumps P-401A are installed at the bottom of the water washing tower / B, carry out circulating water washing on the tail gas, regularly supplement and replace the desalted water according to the analys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com