A kind of drawing and forging method of titanium alloy billet

A technology for titanium alloys and billets, applied in metal processing equipment and other directions, can solve the problems of difficult to maintain consistent deformation, insufficient guarantee of deformation, insufficient process stability, etc., to ensure consistency, achieve refined control, and improve billets. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

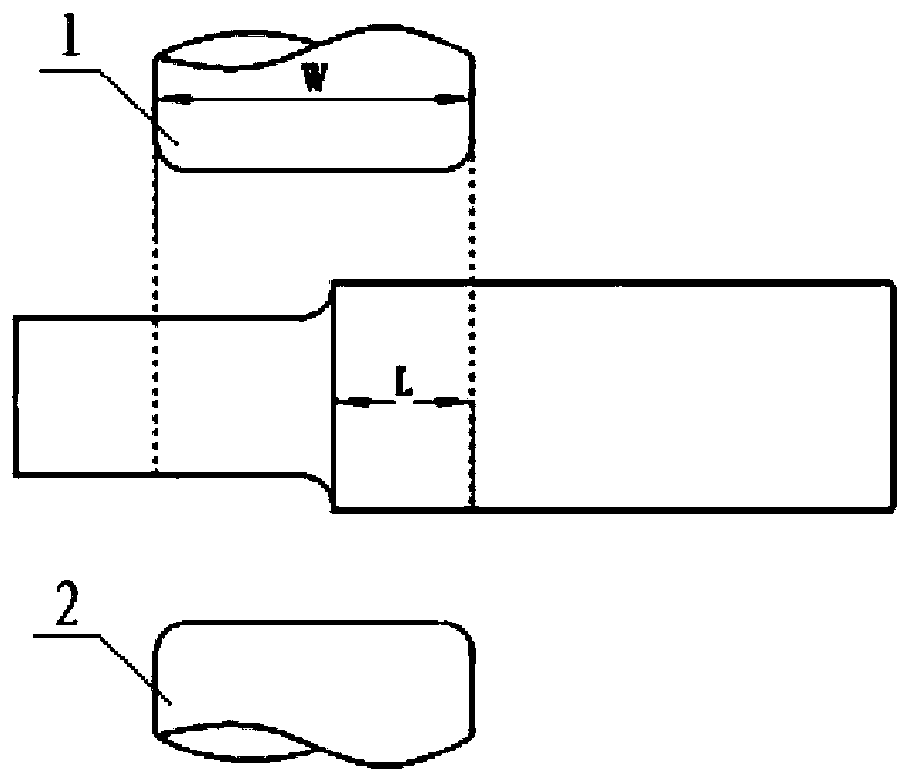

[0032] 1. The coincidence degree coefficient K is selected as 0.2, the width of the upper and lower flat anvils is W=400mm, the determined feed rate is L=192mm, and the side length of the square bar blank after drawing is 155mm;

[0033] 2. Starting from the length of 192mm at one end of the billet, first press down along one side to 155mm, then rotate 90° around the axis of the billet to the other opposite side, and press down again to 155mm, and repeat the above operations until the cross-sectional shape becomes side The square with a length of 155mm completes the final elongation forging of this part of the billet;

[0034] 3. Feed the titanium alloy billet to a length of 192mm;

[0035] 4. Carry out rotary forging according to the forging method described in step 2, until the elongation forging of the titanium alloy bar blank with a length of 192 mm is completed;

[0036] 5. Repeat steps 3 to 4 until the entire titanium alloy billet becomes a square billet with a side len...

Embodiment 2

[0038] The specific implementation method of forging a square edge with a deformation amount A of 35% by using a square titanium alloy bar blank with a side length of 400mm as a blank:

[0039] 1. The coincidence coefficient K is selected as 0.15, the width of the upper and lower flat anvils is W=400mm, the determined feed rate is L=221mm, and the side length of the square bar blank after drawing is 322mm;

[0040] 2. Starting from the length of 221mm at one end of the billet, first press down to 322mm along the diagonal line, then rotate 90° around the billet axis to the other diagonal line, press down again to 322mm, and repeat the above operations until the section The shape becomes a square with a side length of 322mm, and the final elongation forging of this part of the billet is completed;

[0041] 3. Feed the titanium alloy billet to a length of 221mm;

[0042] 4. Carry out rotary forging according to the forging method described in step 2, until the elongation forging...

Embodiment 3

[0045] The specific implementation method of hexagonal elongated forging with a deformation amount A of 45% using a titanium alloy billet with a diameter of 300 mm as a blank:

[0046] 1. The coincidence coefficient K is selected as 0.2, the width of the upper and lower flat anvils is W = 300mm, the determined feed rate is L = 132mm, and the distance between the opposite sides of the hexagonal billet after drawing is 212mm;

[0047] 2. Starting from the length of 132mm at one end of the billet, press down to 212mm, then rotate 60° around the billet axis, press down again to 212mm, and repeat the above operations until the cross-sectional shape becomes a regular hexagonal with a distance of 212mm across, and the completion Final elongation forging of this part of the billet;

[0048] 3. Feed the titanium alloy billet to a length of 132mm;

[0049] 4. Carry out rotary forging according to the forging method described in step 2, until the elongation forging of the titanium alloy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com