Laser pipe cutting chuck signal control device

A signal control and laser cutting technology, which is applied to laser welding equipment, manufacturing tools, tubular objects, etc., can solve the problems of low production tempo, low degree of automation, and low efficiency, so as to reduce labor intensity, improve automation, and improve intelligence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

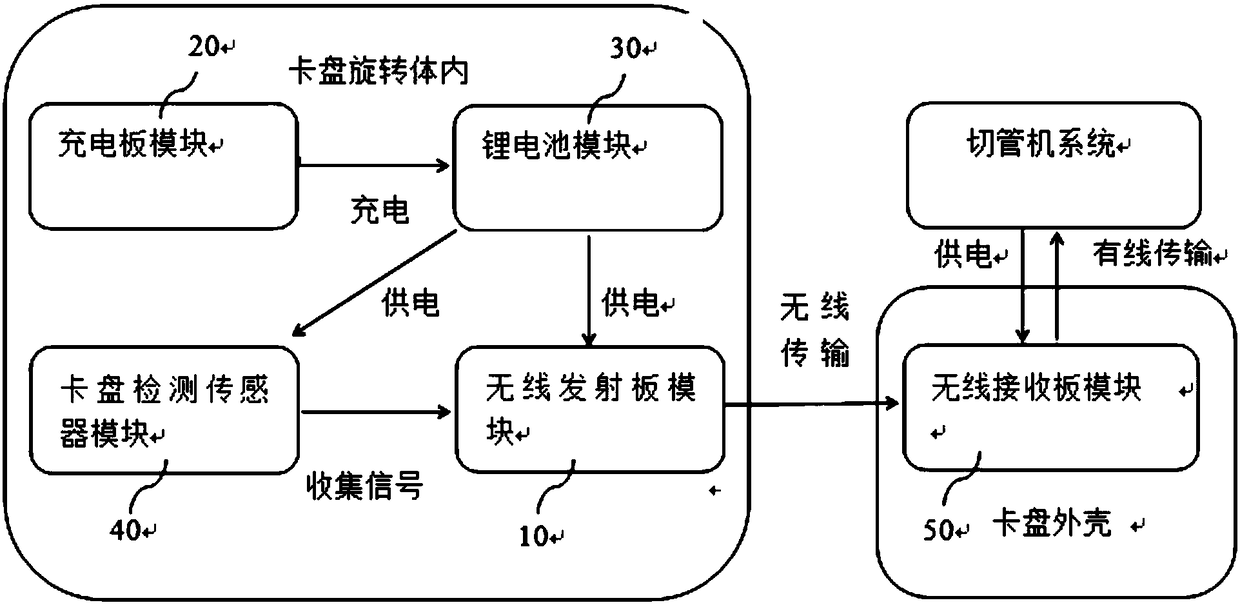

[0022] Such as figure 1 As shown, a kind of cutting pipe chuck signal control device includes: including a wireless launch board module (the main control chip is a 32-bit ARM Cortex-M0 microprocessor bit as the core integrated wireless transmitter and ADC, etc.) 10, a charging board Module 20, battery module 30, chuck detection sensor module 40 and wireless receiving board module (32-bit ARM Cortex-M0 microprocessor is the core integrated hard decoding wireless receiver) 50, preferably, battery module 30 is a lithium battery module . Wherein, the charging board module 20, the lithium battery module 30, the wireless transmitting board 01 module and the chuck detection sensor module 40 are arranged in the rotating body of the chuck, the wireless receiving board module 50 is arranged on the chuck shell, and the lithium battery module 3 is a wireless The launch board module 1 and the chuck detection sensor module 40 provide power; the charging board module 20 provides a charging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com