A kind of modified asphalt pavement material and preparation method thereof

A modified asphalt, road technology, applied in building insulation materials, climate sustainability, sustainable waste treatment, etc., to achieve the effects of enhanced adhesion, increased toughness, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

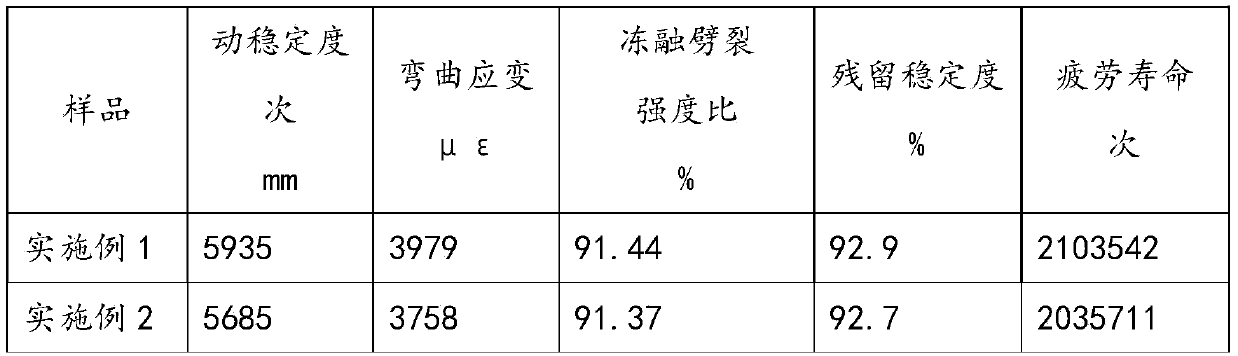

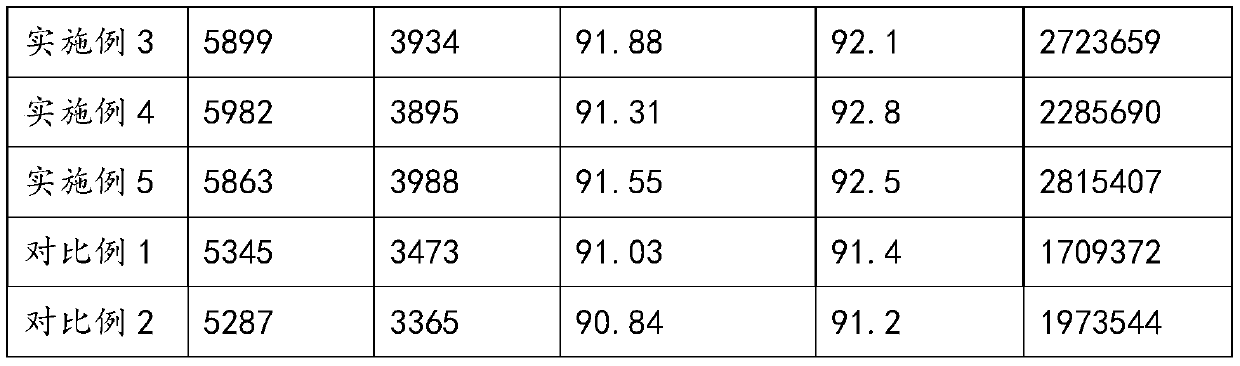

Examples

Embodiment 1

[0026] The raw materials are proportioned according to the following parts by mass:

[0027] 80 parts of aggregate, 8 parts of petroleum asphalt, 1-3 parts of bauxite, 1.0 part of urethane resin, 5 parts of rubber powder particles, 1 part of ethylene-vinyl acetate copolymer, and 1 part of polyvinyl alcohol fiber.

[0028] Prepare modified asphalt pavement materials according to the following steps:

[0029] 1) Preheat and soften the petroleum asphalt at 70°C, add aggregates and bauxite in proportion to the base asphalt, keep the temperature at 80°C, stir in a high-speed shear for 5 minutes at a speed of 360r / min, and obtain a mixture;

[0030] 2) According to the proportion, add urethane resin, rubber powder particles, and ethylene-vinyl acetate copolymer to the above mixture, stir and mix evenly, raise the temperature to 180°C, and set aside; then add polyvinyl alcohol fiber according to the proportion, stir for 1min, The modified asphalt pavement material is obtained.

Embodiment 2

[0032] 75 parts of aggregate, 10 parts of petroleum asphalt, 3 parts of bauxite, 1.0 part of urethane resin, 7 parts of rubber powder particles, 1 part of ethylene-vinyl acetate copolymer, and 0.5 part of polyvinyl alcohol fiber.

[0033] Prepare modified asphalt pavement materials according to the following steps:

[0034] 1) Preheat and soften the petroleum asphalt at 80°C, add aggregates and bauxite in proportion to the base asphalt, keep the temperature at 80°C, stir in a high-speed shearer for 10 minutes at a speed of 240r / min, and obtain a mixture ;

[0035] 2) According to the proportion, add urethane resin, rubber powder particles, and ethylene-vinyl acetate copolymer to the above mixture, stir and mix evenly, raise the temperature to 190°C, and set aside; then add polyvinyl alcohol fiber according to the proportion, and stir for 2 minutes. The modified asphalt pavement material is obtained.

Embodiment 3

[0037] 75 parts of aggregate, 10 parts of petroleum asphalt, 3 parts of bauxite, 1.0 part of urethane resin, 5 parts of rubber powder particles, 1 part of ethylene-vinyl acetate copolymer, and 0.5 part of polyvinyl alcohol fiber.

[0038] Prepare modified asphalt pavement materials according to the following steps:

[0039] 1) Preheat and soften the petroleum asphalt at 100°C, add aggregates and bauxite in proportion to the base asphalt, keep the temperature at 80°C, and stir in a high-speed shear for 5 minutes at a speed of 360r / min to obtain a mixture;

[0040] 2) According to the proportion, add urethane resin, rubber powder particles, and ethylene-vinyl acetate copolymer to the above mixture, stir and mix evenly, raise the temperature to 195°C, and set aside; then add polyvinyl alcohol fiber according to the proportion, and stir for 5 minutes. The modified asphalt pavement material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com