Water transfer film with concave and convex effects and preparation method thereof

A technology of water transfer printing film and concave pattern, which is applied in the field of concave-convex effect water transfer printing film and its preparation, can solve the problems of no three-dimensional effect on the pattern plane, environmental pollution, etc., and achieve the goal of reducing soluble PVA, reducing costs, and low production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

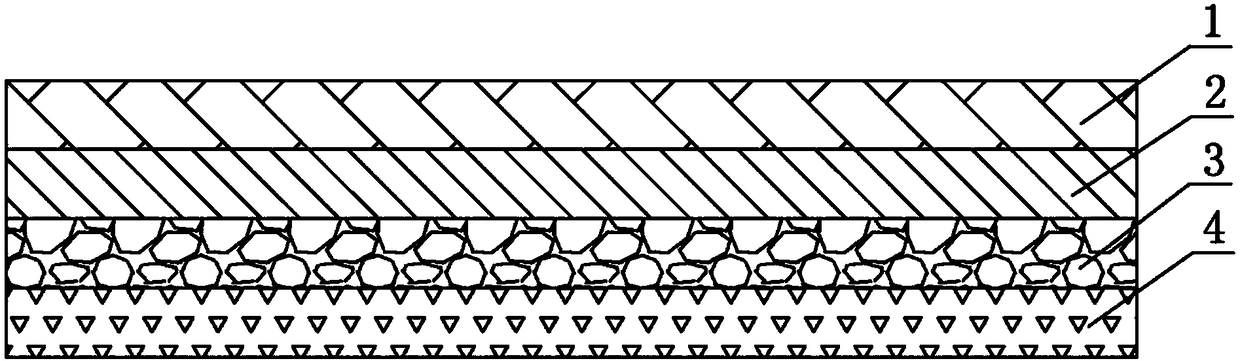

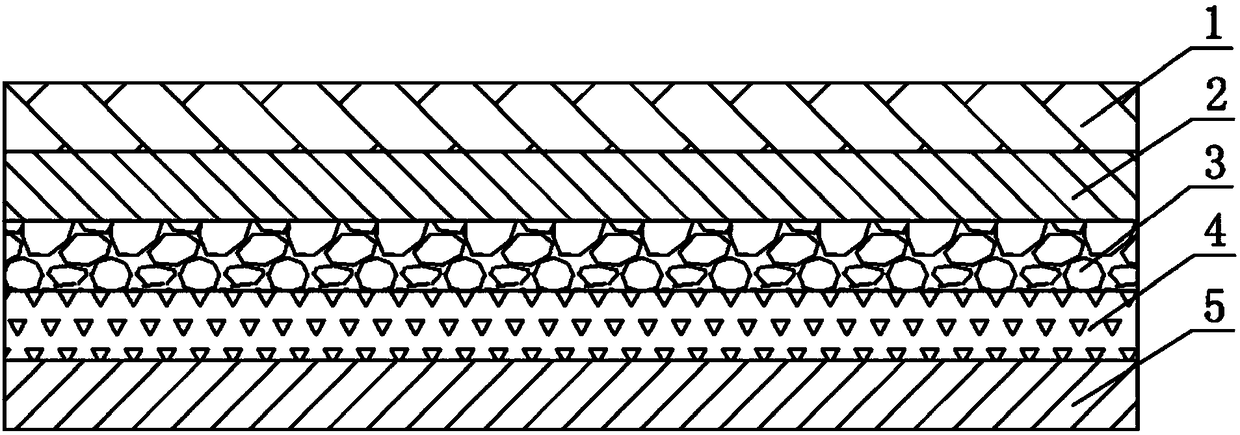

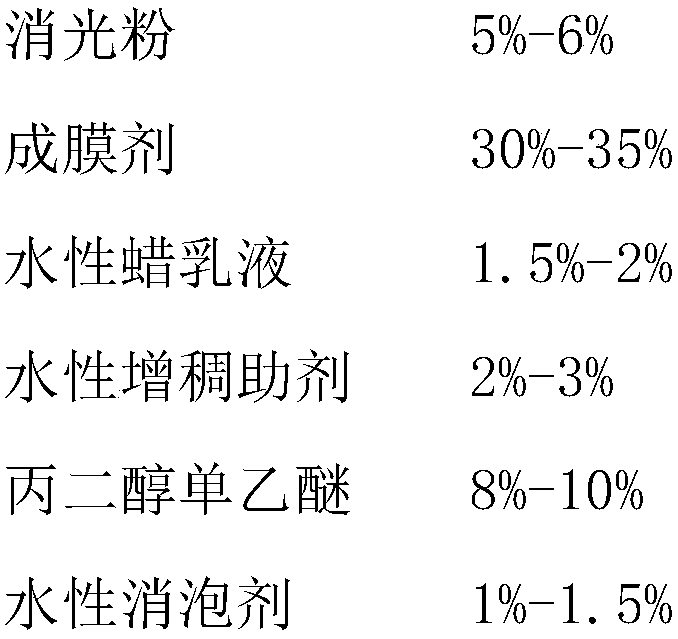

[0041] See figure 1 , a concave-convex effect water transfer film, comprising a water-soluble base film layer 1, a concave layer 2, a release protective layer 3 and an ink pattern layer 4, which are laminated sequentially from top to bottom, and the concave layer 2 is made of water-based paint Formed by coating, the water-based coating is composed of the following raw materials in weight percentage:

[0042]

[0043] The matting powder is fumed silica produced by Degussa, Germany, whose model is OK412.

[0044] Described film-forming agent is the polyvinyl alcohol of model PVA205 that Japanese Kuraray produces.

[0045] The aqueous wax emulsion is a BYK-AQUACER498 aqueous wax emulsion produced by BYK in Germany.

[0046] The water-based thickening aid is the water-based thickening aid of the model K-STAY720 produced by King's in the United States.

[0047] The water-based defoamer is a BYK-024 water-based defoamer produced by BYK, Germany.

[0048] A method for preparin...

Embodiment 2

[0054] The difference between this embodiment and above-mentioned embodiment 1 is: described water-based coating is made up of the raw material of following percentage by weight:

[0055]

Embodiment 3

[0057] The difference between this embodiment and above-mentioned embodiment 1 is: described water-based coating is made up of the raw material of following percentage by weight:

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com