Multi-hole tool anchor and prestress tensioning system of steel strands

A technology of tool anchors and steel strands, which is applied in the direction of lifting devices, erecting/assembling bridges, bridge materials, etc., which can solve the problems of broken or slipped wires, excessive loss of effective prestress, and influence on the relaxation performance of prestress beams And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

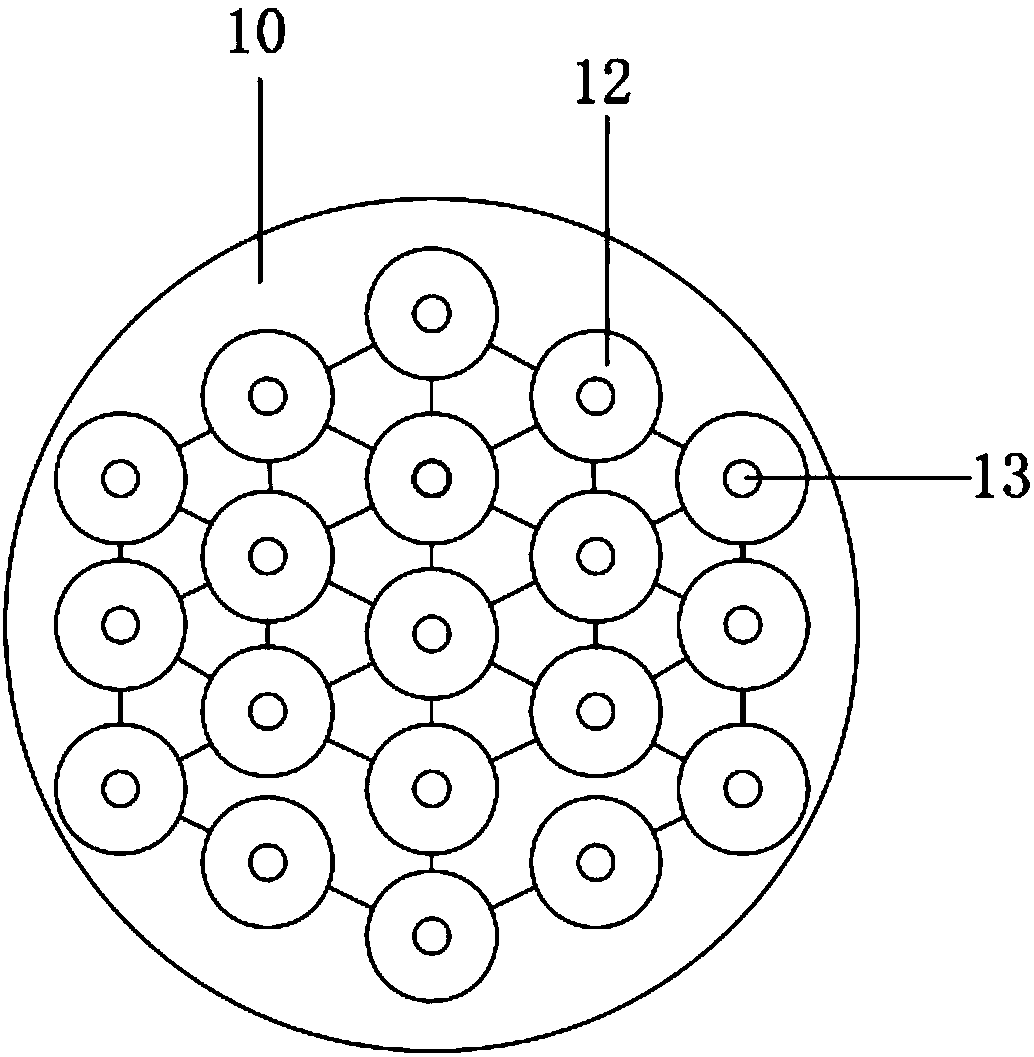

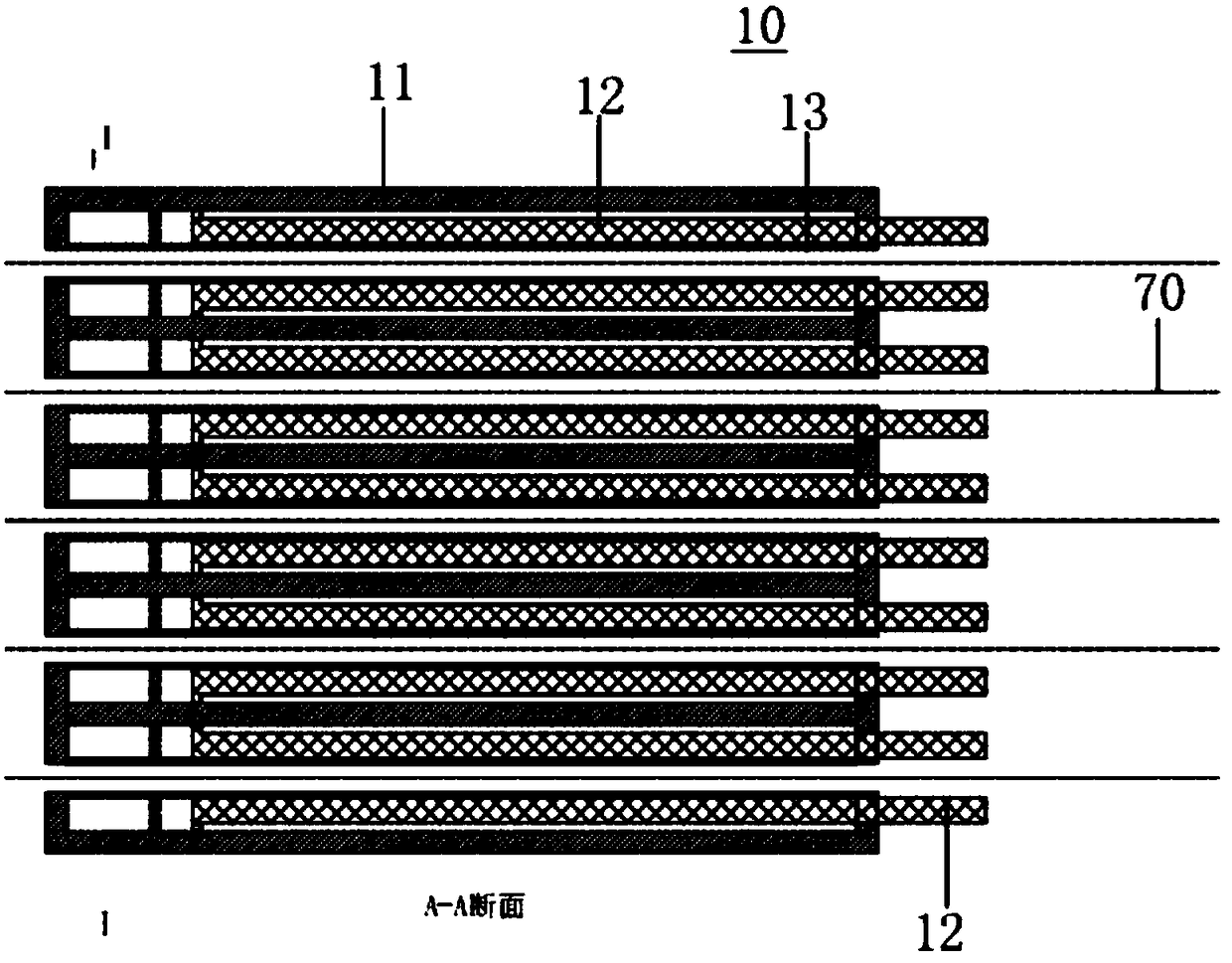

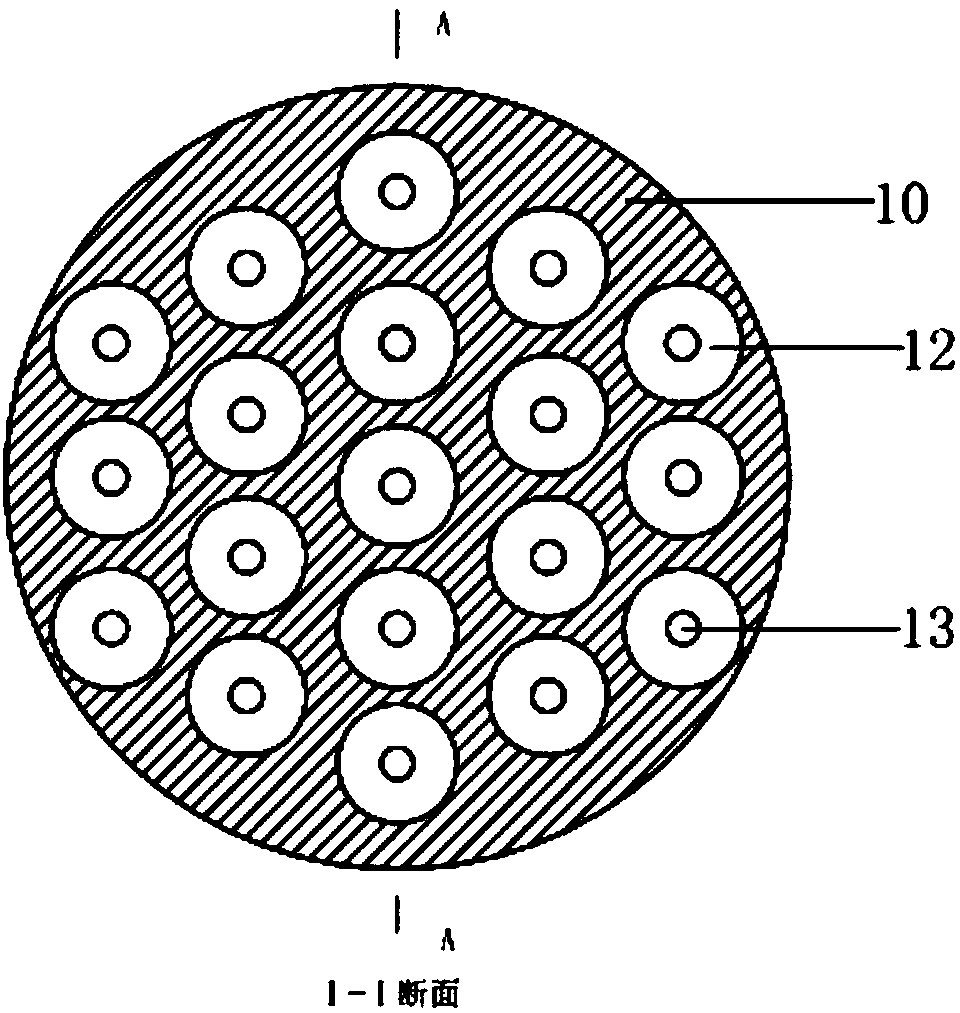

[0023] see figure 1 , and combined with figure 2 As shown, the present invention provides a porous tool anchor, which includes an anchor plate base 10, on which a plurality of interconnected cylinders 11 are arranged, and a tubular piston 12 is installed in the cylinders 11, and The middle part of the piston 12 is provided with a threading through hole 13 .

[0024] During use, a steel strand 70 is arranged in each threading through hole 13. Since the cylinder body 11 is interconnected, the pulling force received by each piston 12 is also the same, so that each steel strand 70 is also subjected to the same pulling force. Preferably, the cylinders 11 communicate with ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com