Magnetic suspension plate-shaped rigid damping sound insulation cushion

A technology of shock absorption, sound insulation and magnetic levitation, applied in the direction of springs/shock absorbers, shock absorbers, magnetic springs, etc., can solve the problems of insufficient isolation effect and low sound source conductivity, and achieve a wide range of use environments, Low sound source conductivity and good electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

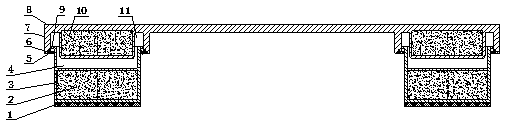

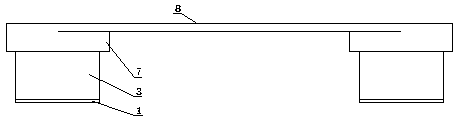

[0018] Example 1, such as Figure 1-5 As shown, the present embodiment provides a specific structure of a magnetic levitation plate-shaped rigid shock-absorbing and sound-insulating pad, including a shock-absorbing and sound-insulating pad body, and the shock-absorbing and sound-insulating pad body mainly includes the following parts: magnet, support sheath 3, non-metallic plate Shaped rigid pad8. Wherein the magnet comprises a lower high magnetic magnet 2 and an upper high magnetic magnet 10, the lower high magnetic magnet 2 and the upper high magnetic magnet 10 are facing up and down, and the opposite ends of the lower high magnetic magnet 2 and the upper high magnetic magnet 10 have the same polarity , to generate the same-sex repulsion magnetic levitation force. There are four supporting sheaths 3 for supporting the upper high magnetic magnet 10 and the lower high magnetic magnet 2, which are respectively arranged at the four corners of the lower high magnetic magnet 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com