Anti-freezing device for coal mine shaft

A technology for shafts and coal mines, applied in the field of antifreeze equipment for coal mine shafts, can solve the problems of low efficiency, substandard environmental protection, large energy consumption of coal-fired boilers, etc., and achieves the effects of improving thermal efficiency, significant thermal efficiency, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

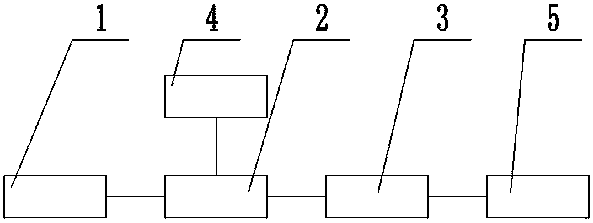

[0014] Such as figure 1 , figure 2 As shown, the coal mine shaft antifreeze equipment of the present invention includes a power module 1, an electric heating module 2, a hot air delivery module 3 and a power supply module 4, one end of the electric heating module 2 is connected to the power module 1, and the other end of the electric heating module 2 One end is connected with a hot air delivery module 3, and the power supply module 4 is connected to the electric heating module 2 for supplying power to the electric heating module 2, and the electric heating module 2 transmits the heat generated by the power module 1 through the hot air delivery module 3. Mine shaft shaft roadway 5;

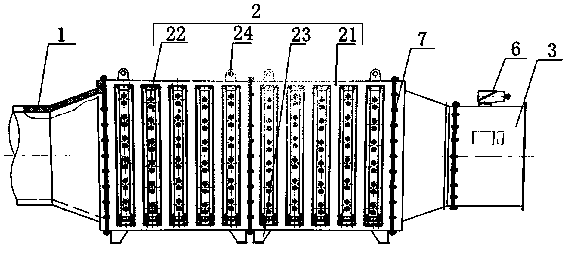

[0015] The structure of the electric heating module 2 is as follows: it includes a plurality of cylinders 21, which are connected together in turn, and a plurality of heating belts 22 are arranged on the outside of the cylinders 21, and the bottom of the cylinders 21 A plurality of supports 23 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com