A flow control nozzle

A technology of flow control and nozzle, which is applied in the field of nozzle with high-precision adjustment of gas flow, can solve the problems of limiting the accuracy of flow adjustment, and achieve the effect of compact nozzle structure, easy repair and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

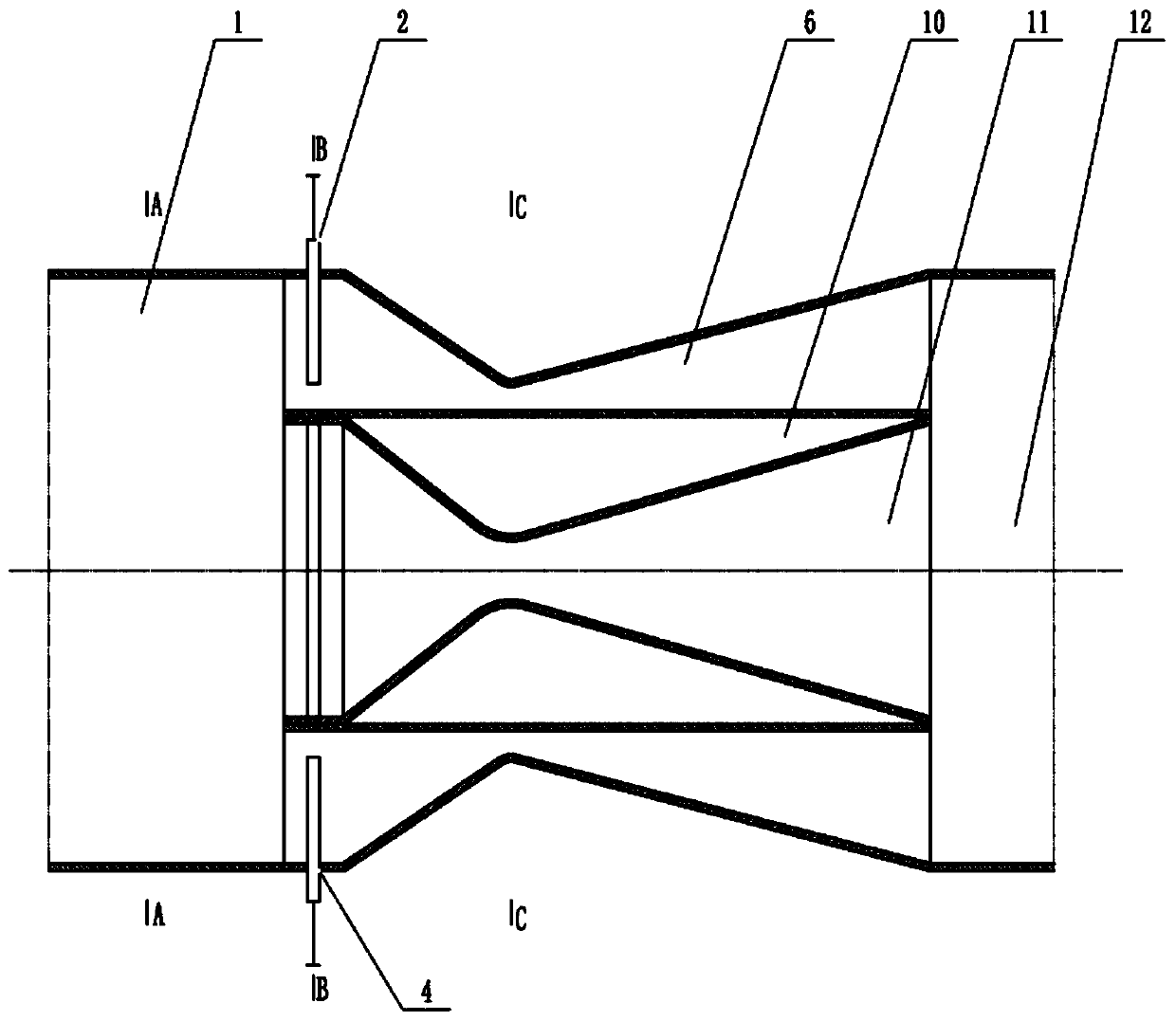

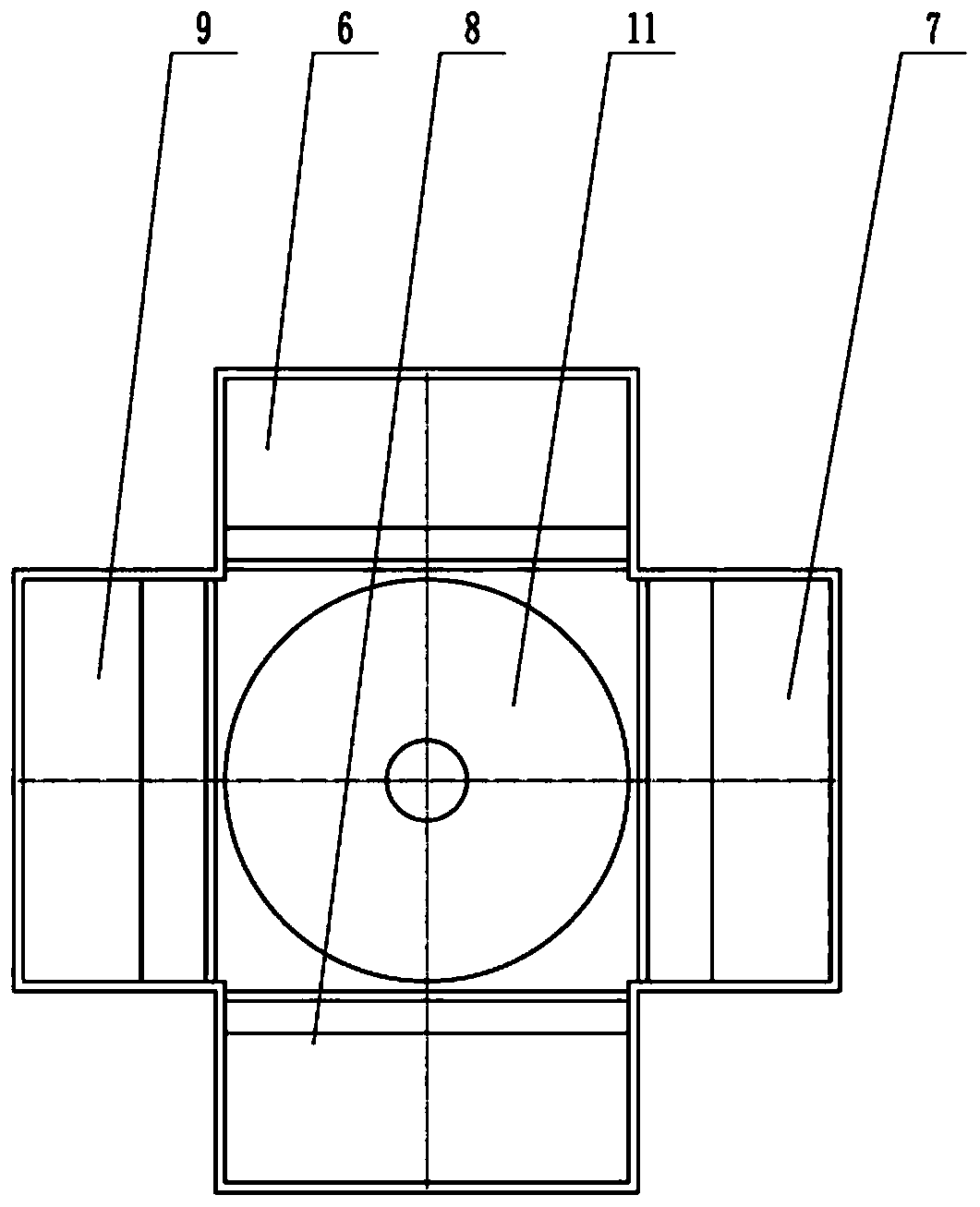

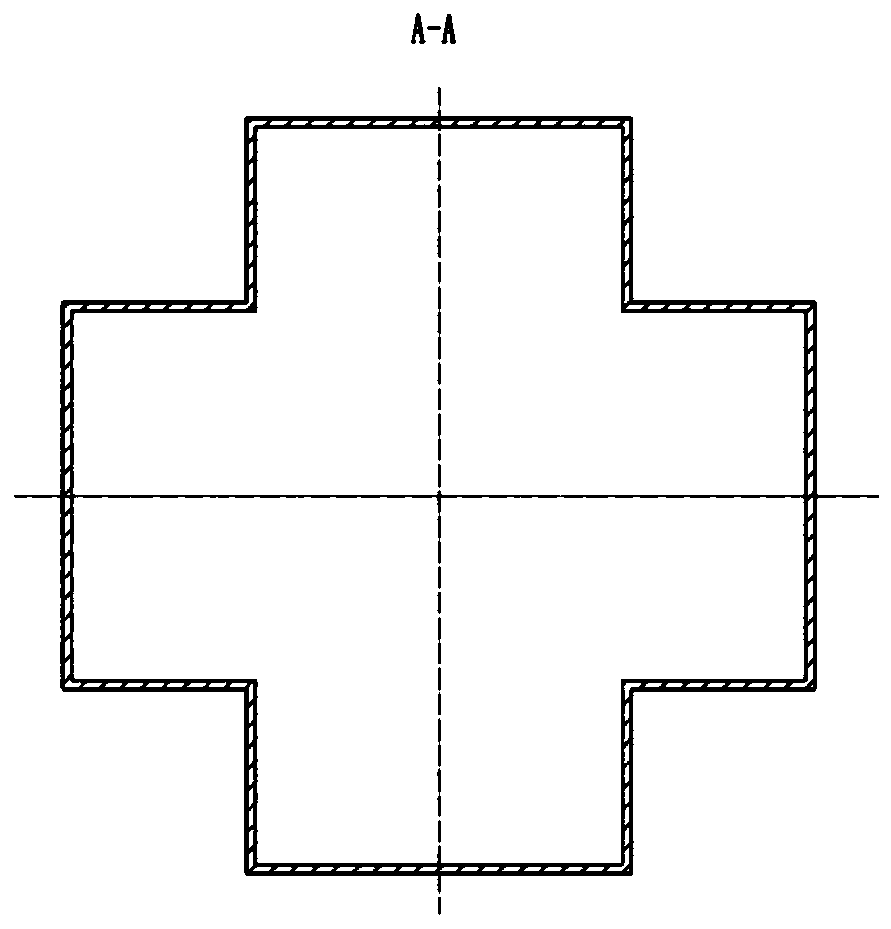

[0022] Such as figure 1 As shown, the structure diagram of the gas flow control nozzle, the nozzle includes a pressure stabilizing section 1, an upper flapper valve 2, a right flapper valve 3, a lower flapper valve 4, a left flapper valve 5, and an upper binary nozzle 6 , right binary nozzle 7, lower binary nozzle 8, left binary nozzle 9, nozzle structure block 10, center ternary nozzle 11, diffusion section 12; wherein the main function of voltage stabilizing section 1 is to reduce The flow velocity of the gas at the inlet of the nozzle improves the stability of the air flow and reduces the degree of turbulence. The front end connection of the gate valve 5 gradually transitions into a special-shaped structure, such as figure 2 shown. The upper flapper valve 2, the right flapper valve 3, the lower flapper valve 4, and the left fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com