Plastic film printing character defect detection device and method

A plastic film and defect detection technology, which is applied in the direction of measuring devices, optical testing of defects/defects, and analysis of materials, can solve problems such as broken strokes, white spots, and difficulty in detecting narrow character information, achieving intelligent and efficient detection , avoid the effect of high cost of manual participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in combination with specific embodiments.

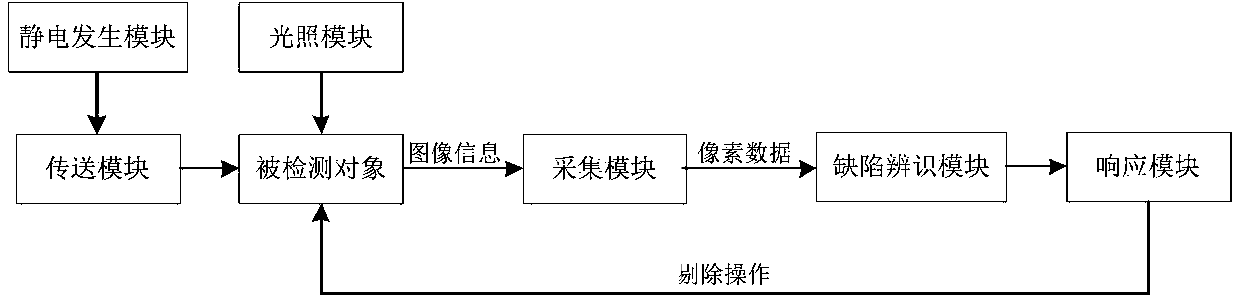

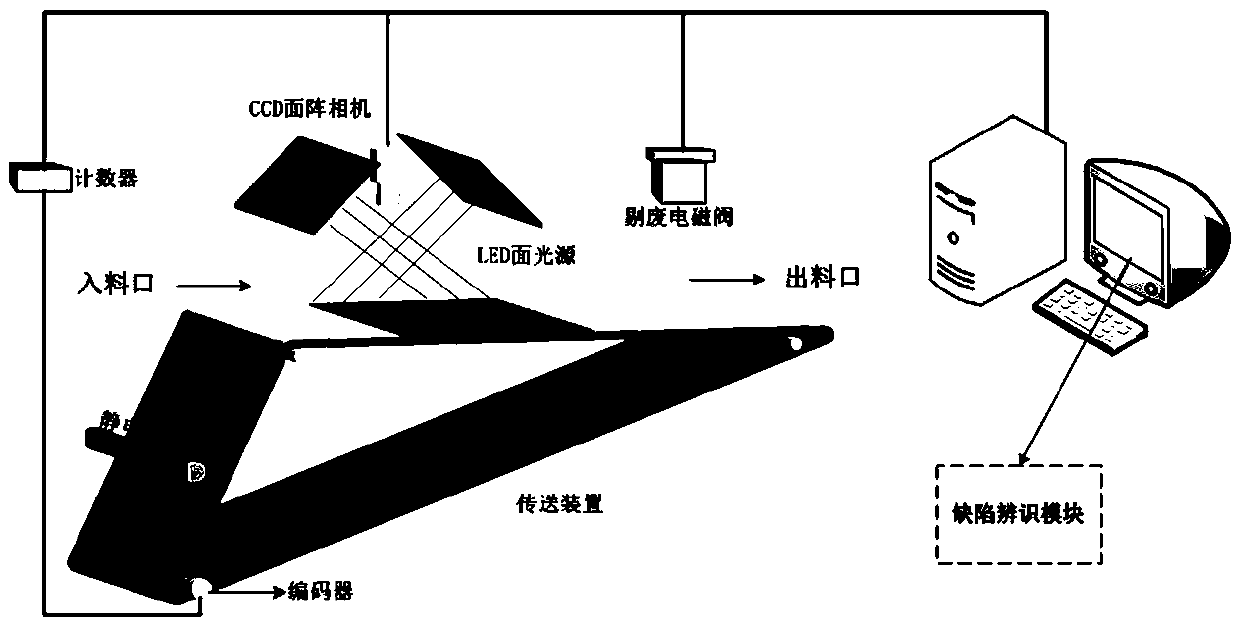

[0038] The invention relates to a device and method for detecting defects of characters printed on a plastic film. The device includes a static electricity generation module, a transmission module, a lighting module and a collection module.

[0039] The static electricity generation module acts on the transmission module, which is used to make the surface of the transmission device in the transmission module continue to have electrostatic adsorption force, and complete the smooth transmission of the film product to be tested; the transmission module completes the fixing and transmission of the product; the light module acts on the object to be detected On the surface, it is used to make the product surface in the detection area have uniform illumination; the acquisition module completes the complete acquisition and transmission of image data.

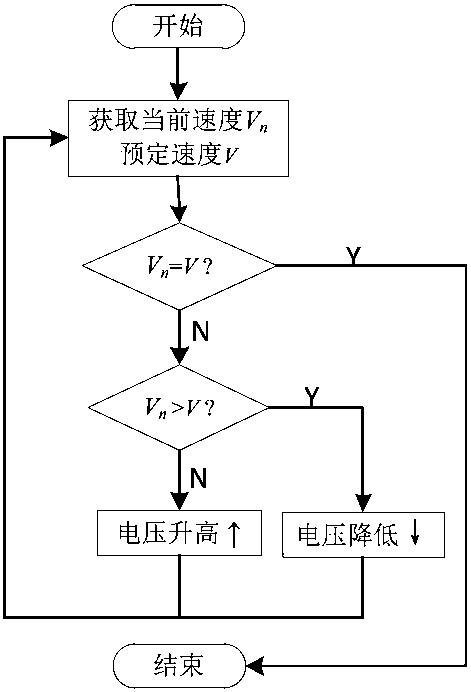

[0040] The electrostatic ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com