Glue frictioning device applied to printing and textile industries and AB glue coating method

A squeegee, an industry-leading technology, applied in the field of clothing printing, can solve the problems of not meeting the process requirements, uncontrollable film forming area, and substandard film thickness, etc., to achieve low production cost, controllable gluing area, and stress-resistant and uniform film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

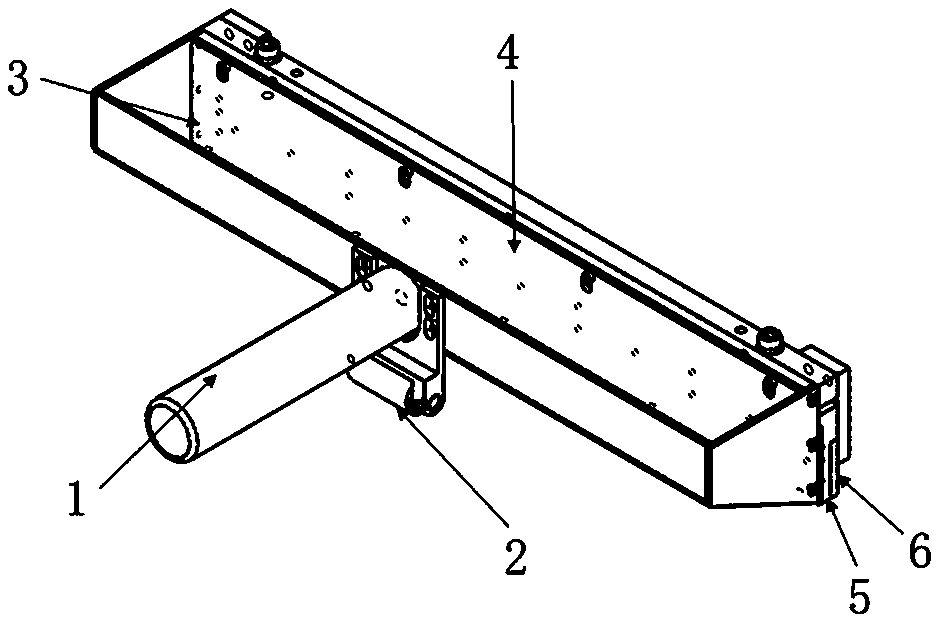

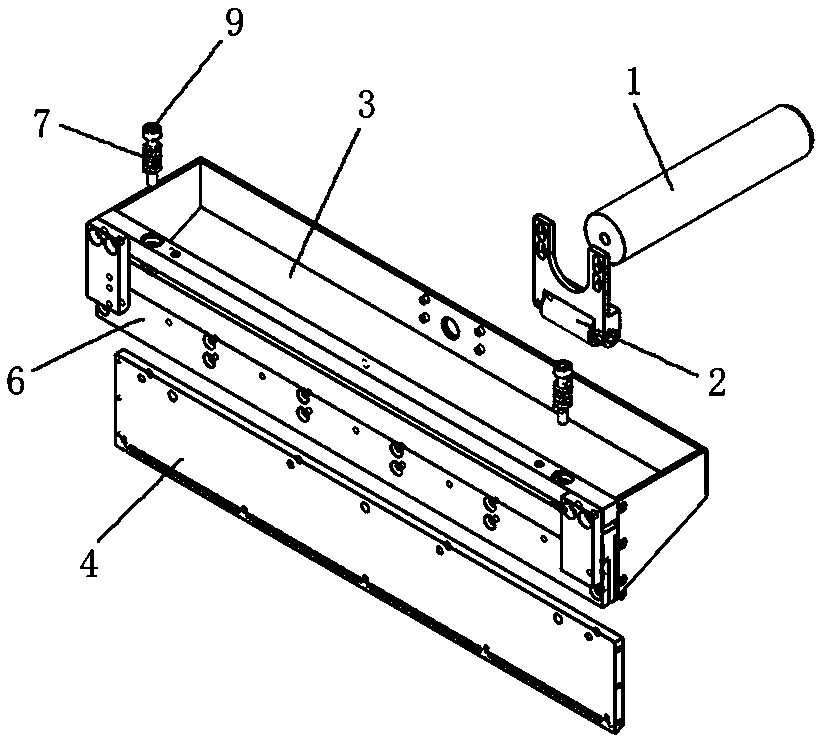

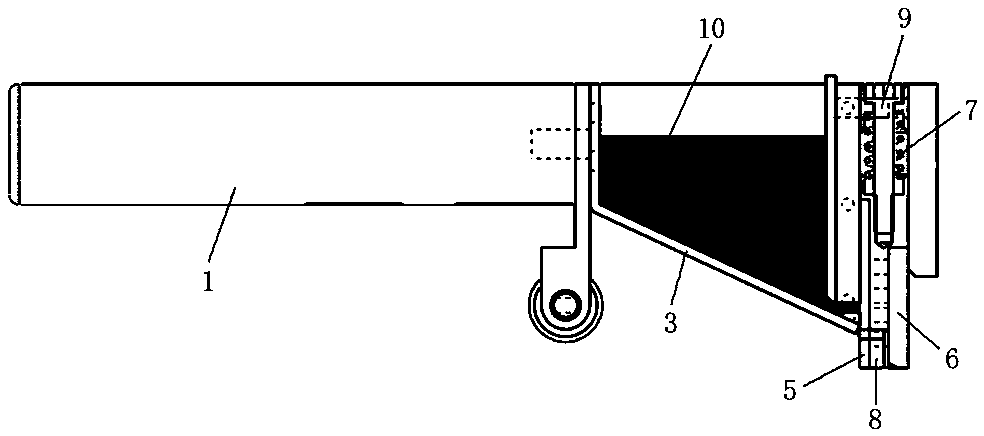

[0015] Such as Figure 1 to Figure 4 As shown, a squeegee used in the printing and textile industries is mainly composed of a handle 1, a guide roller 2, a glue tank 3, a flow regulating plate 4, a rubber baffle 5 and a scraper 6; the handle 1 is fixedly connected with the glue holding tank 3, the guide roller 2 is fixedly connected to the back of the glue holding tank 3 directly below the handle 1, the flow regulating plate 4 is fixedly connected to the front of the glue holding tank 3, and the front of the glue holding tank 3 A scraper 6 is fixedly connected to the bottom of the rubber tank 3, and a rubber baffle 5 is fixedly connected to the lower edge of the glue tank 3. The gap between the rubber baffle 5 and the scraper 6 forms a diversion groove for the rubber material 10 to flow out. 8. Two guide pillars 9 are arranged on the groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com