Environment-friendly compound polyurethane catalyst for polyurethane

A polyurethane catalyst, an environmentally friendly technology, applied in the field of environmentally friendly compound polyurethane catalysts for polyurethane, can solve the problems of high biological toxicity, reduce the comprehensive performance of polyurethane, use and development restrictions, etc., and achieve high gelation efficiency and high safety , Excellent peel strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

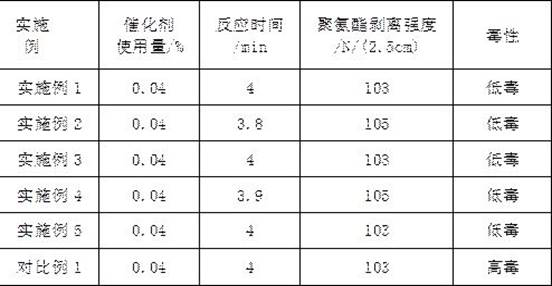

Examples

Embodiment 1

[0021] An environment-friendly composite polyurethane catalyst for polyurethane, comprising the following raw materials formulated by weight percentage: 40% bismuth octadecanoate, 25% zinc octadecanoate, 15% stannous octanoate, and 20% octadecanoate;

[0022] The preparation method of the environment-friendly composite polyurethane catalyst for the polyurethane is as follows: add octadecanoic acid, bismuth octadecanoate, and zinc octadecanoate successively in a stirred tank, stir for 10 minutes, then add stannous octanoate, and stir for 10 minutes to obtain a composite polyurethane catalyst. With catalyst.

Embodiment 2

[0024] An environment-friendly composite polyurethane catalyst for polyurethane, comprising the following raw materials prepared by weight percentage: 40% bismuth naphthenate, 25% zinc octadecanoate, 15% stannous octanoate, 20% octadecanoate;

[0025] The preparation method of the environment-friendly composite polyurethane catalyst for the polyurethane is as follows: add octadecanoic acid, bismuth naphthenate, and zinc octadecanoate successively in a stirred tank, stir for 10 minutes, then add stannous octanoate, and stir for 10 minutes to obtain a composite polyurethane catalyst. With catalyst.

Embodiment 3

[0027] An environment-friendly composite polyurethane catalyst for polyurethane, comprising the following raw materials prepared by weight percentage: 40% bismuth naphthenate, 25% zinc lactate, 15% stannous octoate, 20% octadecanoic acid;

[0028] The preparation method of the environment-friendly composite polyurethane catalyst for polyurethane is as follows: add naphthenic acid, bismuth naphthenate, and zinc lactate in turn in a stirred tank, stir for 10 minutes, then add stannous octoate, and stir for 10 minutes to obtain the composite catalyst .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com