Film-making machine

A film making machine and chassis technology, which is applied to flat products, other household appliances, household appliances, etc., can solve the problems of poor drying effect of film materials and large floor space, so as to prevent excessive temperature and reduce floor space. area, the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing.

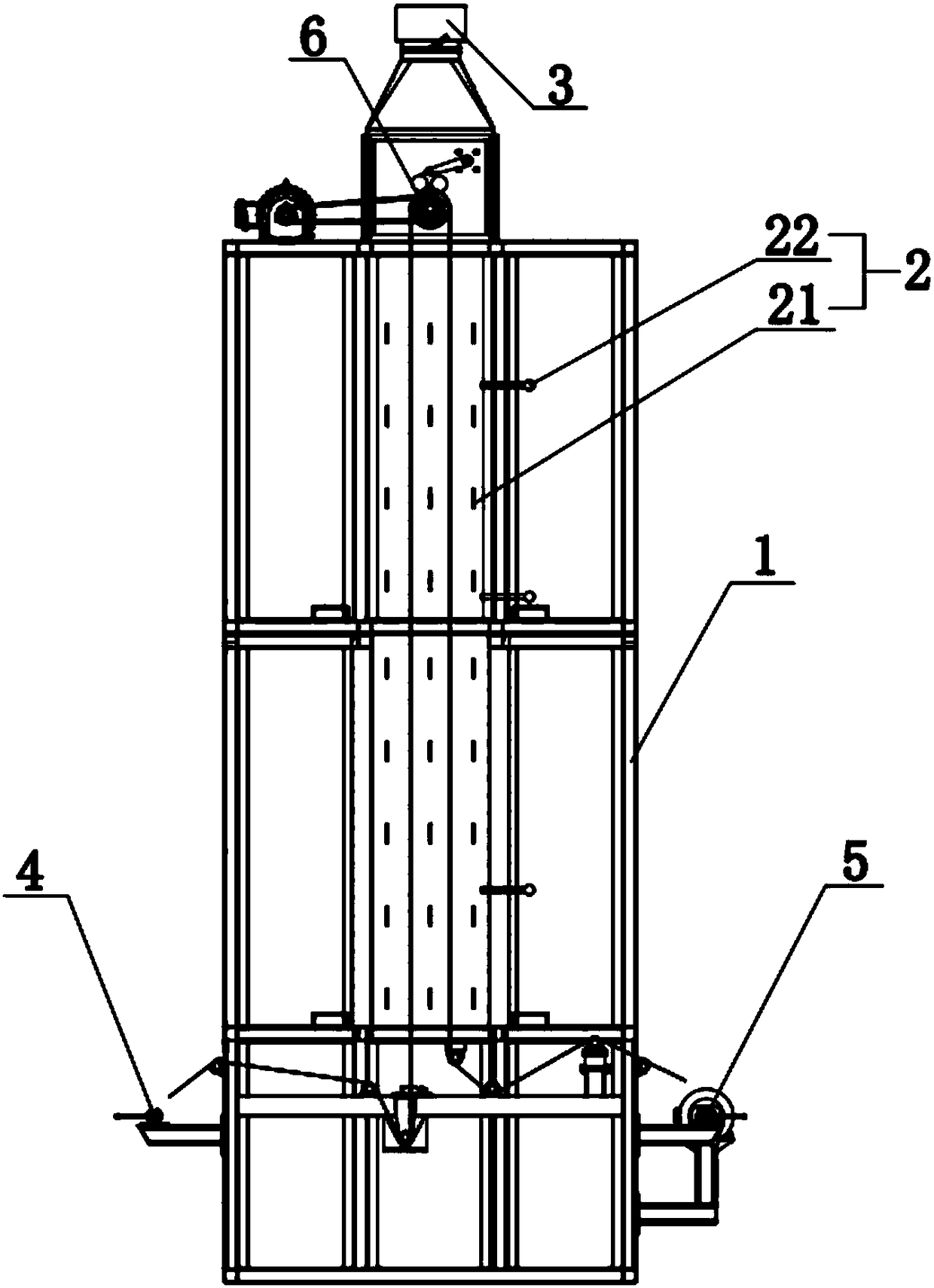

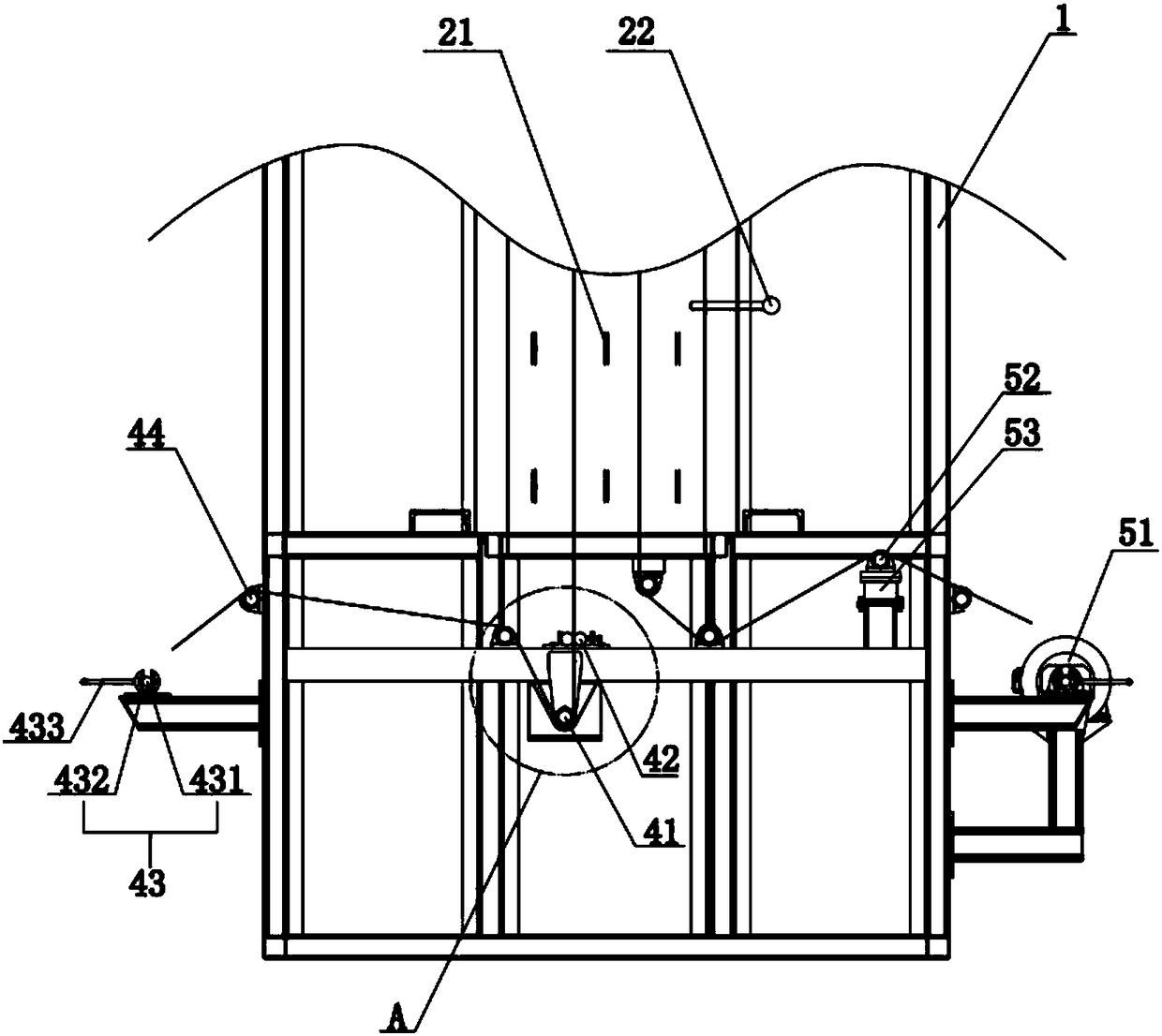

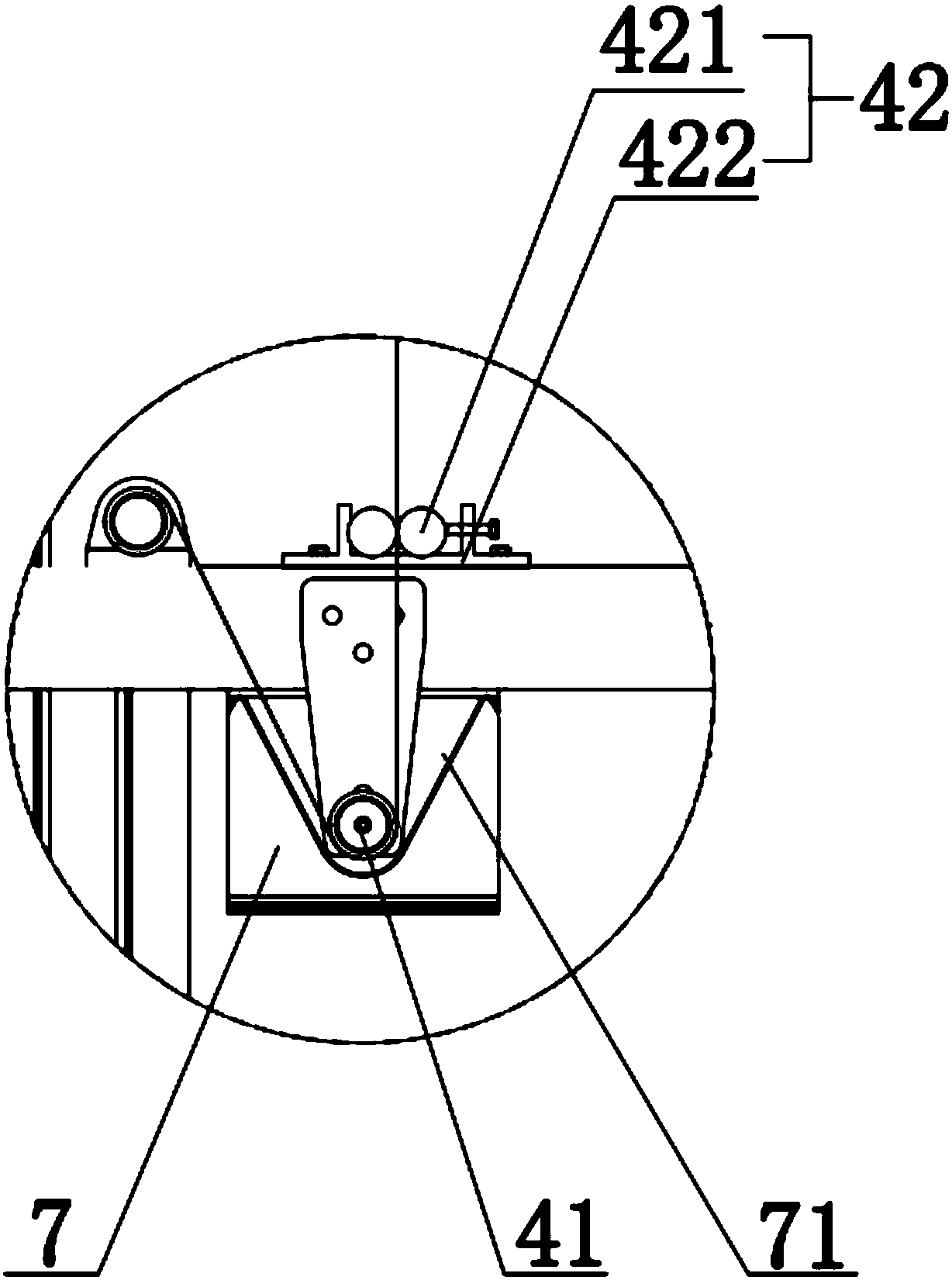

[0038] Such as figure 1 with 2 As shown, the present invention provides a film making machine, including a cabinet 1 , a drying device 2 and a blower 3 . Wherein, the left and right sides of the lower part of the cabinet 1 are respectively provided with a feeding device 4 and a discharging device 5, and the upper part of the cabinet 1 is provided with a traction device 6 for changing the direction of travel of the film material. The drying device 2 is arranged inside the cabinet 1, and the film material enters the drying device 2 from the feeding device 4 from bottom to top, changes the walking direction through the traction device 6, passes through the drying device 2 from top to bottom and exits from the outlet. Unloaded from the material device 5.

[0039] During the drying process of the membrane material, air is fed into the drying device 2 by the fan 3 arranged at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com