Synthetic method of low-solvent block silicone oil and hand feeling finishing agent containing low-solvent block silicone oil

A technology of block silicone oil and synthesis method, which is applied in the direction of improved hand feeling fiber, fiber treatment, textiles and papermaking, etc., can solve the problems of easy demulsification, high cost, yellowing, etc., and achieve the effect of improving flexibility and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

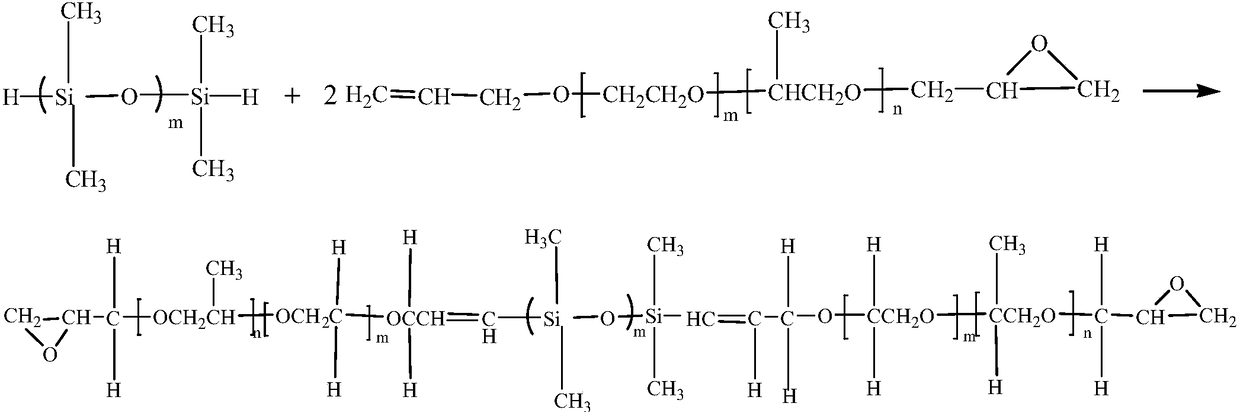

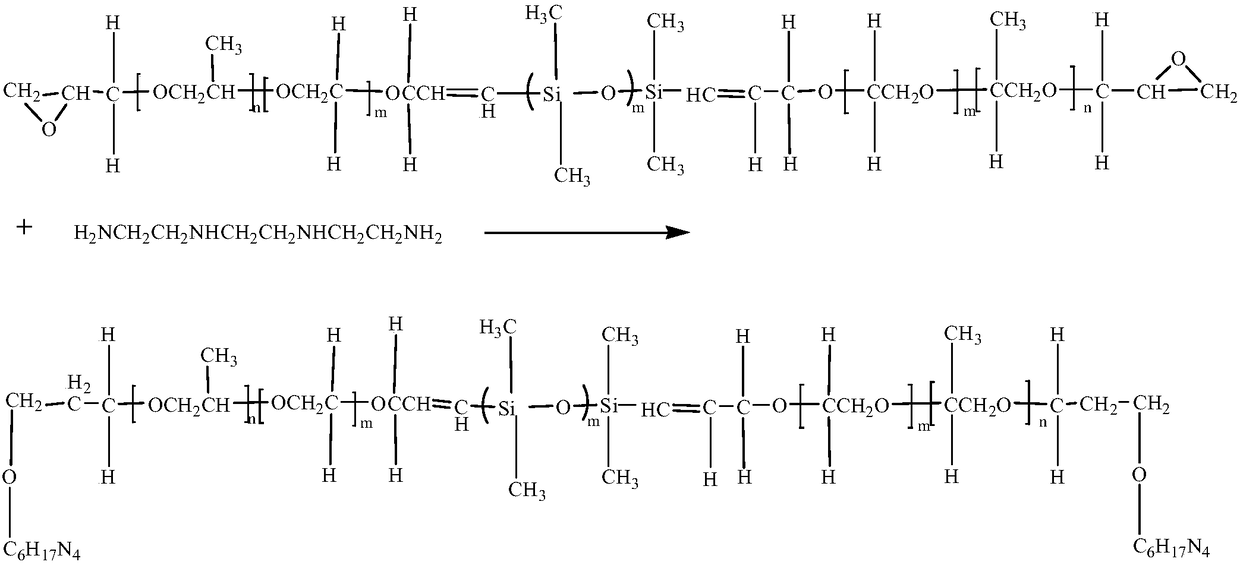

[0022] A method for synthesizing low-solvent block silicone oil, comprising the following steps: step 1, adding terminal low hydrogen-containing silicone oil and allyl epoxy polyether with a molar ratio of 1:2 to the reaction kettle, wherein the terminal low hydrogen-containing silicone oil The molecular weight of allyl epoxy polyether is 4000, and the molecular weight of allyl epoxy polyether is 500-2000. Then add a certain amount of isopropanol into the reaction kettle, heat the reaction kettle to 70°C, stir evenly, then add a certain amount of chloroplatinic acid, keep it warm for 4 hours, then cool down to below 40°C and discharge to obtain the intermediate ; Step 2, put the intermediate and diethylenetriamine with a molar ratio of 1:1 into the reactor, keep the reaction at 80°C for 12 hours, cool down to below 40°C and discharge to obtain low-solvent block silicone oil. The weight ratio of isopropanol to all the materials in the reactor in step 1 is 5:100, and the weight ...

Embodiment 2

[0024] A method for synthesizing low-solvent block silicone oil, comprising the following steps: step 1, adding terminal low hydrogen-containing silicone oil and allyl epoxy polyether with a molar ratio of 1:2 to the reaction kettle, wherein the terminal low hydrogen-containing silicone oil The molecular weight of allyl epoxy polyether is 4000, and the molecular weight of allyl epoxy polyether is 500-2000. Then add a certain amount of isopropanol into the reaction kettle, heat the reaction kettle to 70°C, stir evenly, then add a certain amount of chloroplatinic acid, keep it warm for 4 hours, then cool down to below 40°C and discharge to obtain the intermediate ; Step 2, put the intermediate and diethylenetriamine with a molar ratio of 1:2 into the reactor, keep the reaction at 80°C for 4 hours, cool down to below 40°C and discharge to obtain low-solvent block silicone oil. The weight ratio of isopropanol to all the materials in the reactor in step 1 is 5:100, and the weight r...

Embodiment 3

[0026] A fabric handle finishing agent. Add AEO-3 emulsifier to the low-solvent block silicone oil, emulsify according to the ratio of oil to milk ratio 3:1, add 1% glacial acetic acid to the emulsion, form a transparent or milky white uniformly dispersed emulsion, and obtain the fabric handle finishing agent .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com