Low-VOC (volatile organic compound) polypropylene composite material and preparation method thereof

A composite material and polypropylene technology, applied in the field of low VOC polypropylene composite material and its preparation, can solve the problems of low devolatilization efficiency, reduced VOC removal effect, and reduced effective time, so as to suppress aldehyde and ketone pollution, improve VOC removal efficiency and VOC reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

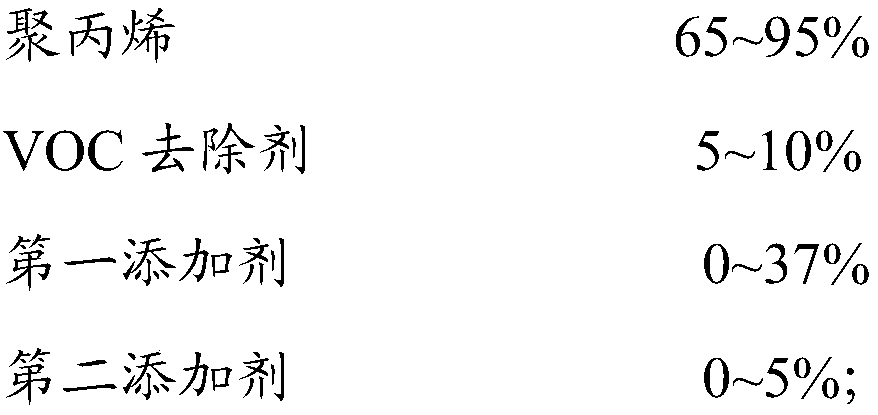

Method used

Image

Examples

Embodiment 1

[0044] A VOC remover is a mixture, the mixture includes a stripping agent, fumed silica and a styrenic block copolymer, the stripping agent is isopropanol, and the styrenic block copolymer is At least one of styrene-butadiene-styrene block copolymer, styrene-isoprene-styrene block copolymer or styrene-ethylene-butylene-styrene block copolymer, so In the VOC remover, the mass percentages of each component are as follows:

[0045] Stripping agent 8%

[0046] Fumed silica 12%

[0047] Styrenic block copolymer 80%.

[0048] According to the above formula, each component was weighed and put into a mixer, the temperature was controlled at 30° C., the stirring speed was 200 r / min, and stirred at a constant speed for 25 minutes to obtain the VOC remover.

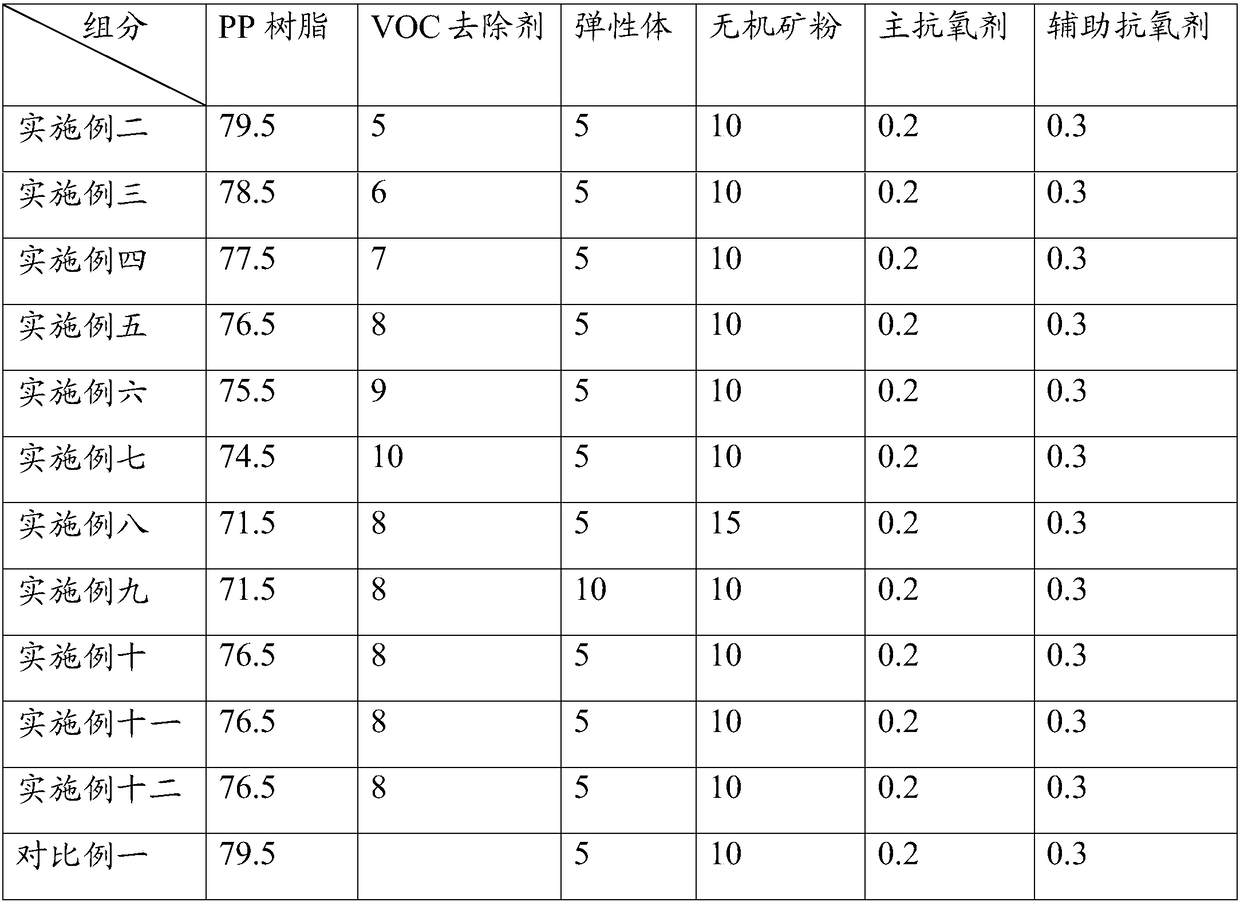

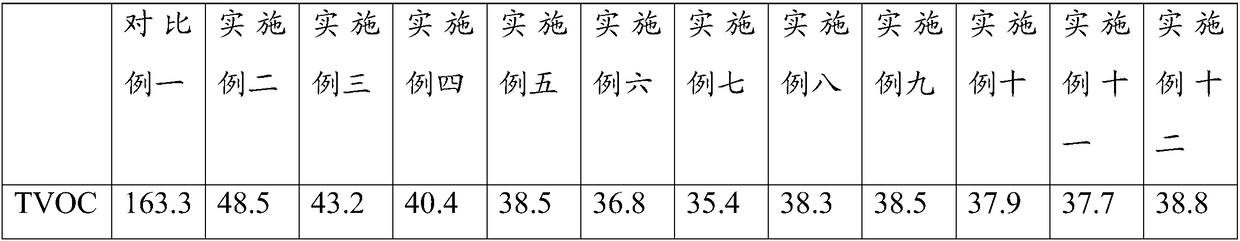

Embodiment 2 9

[0050] A low-VOC polypropylene composite material, comprising polypropylene resin, the VOC remover described in Example 1, a first additive and a second additive, the first additive comprising elastomer, inorganic mineral powder and antioxidant, the Elastomer is the ethylene-octene copolymer POE8999 that DOW company manufactures, and described inorganic mineral powder is the talc powder of commercially available average particle diameter 5 μ m, and described antioxidant comprises main antioxidant and secondary antioxidant, and described main The antioxidant is commercially available primary antioxidant 1010, and the secondary antioxidant is commercially available secondary antioxidant 168. In this embodiment, the addition amount of the second additive is 0. The raw material formula of each component of the low-VOC polypropylene composite material is shown in Table 1, and its preparation method comprises the following steps:

[0051] Weigh polypropylene resin, elastomer, inorga...

Embodiment 10

[0053]The difference between embodiment ten and embodiment five is that polypropylene resin, elastomer, inorganic mineral powder and antioxidant are weighed according to the formula, mixed on a high-speed mixer for 8 minutes, and then added from the main feeding port of the twin-screw extruder . The raw material formula of each component of the low-VOC polypropylene composite material is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com