Low-VOC (volatile organic compound) water-based bi-component epoxy zinc-rich coating and preparation method thereof

An epoxy zinc-rich coating, water-based epoxy technology, applied in the field of coatings, can solve the problems affecting processing and use performance, difficult to meet construction requirements, water resistance not up to standard, etc., to reduce the amount of VOC, reduce viscosity, and not easy to precipitate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

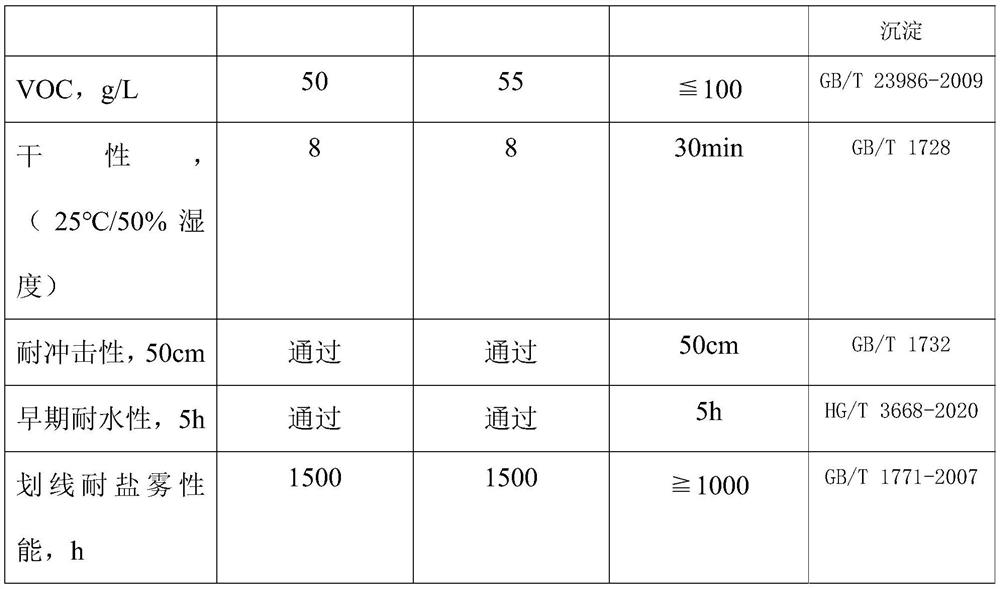

Embodiment 1

[0060] A preparation method of low-VOC waterborne two-component epoxy zinc-rich paint, comprising the following steps:

[0061] S00, material preparation

[0062] Component A: Weigh low-viscosity modified water-based epoxy resin 11, propylene glycol methyl ether 0.5, 800 mesh zinc powder 82, dispersant VXW6208 1.2, filler barite powder NB45 5, anti-settling agent CLAYTONE APA 0.3.

[0063] Component B: weigh 37.5 parts by weight of water-based epoxy curing agent, 62 parts of deionized water, and 0.5 part of anti-flash rust agent;

[0064] Low-viscosity modified water-based epoxy resin: Weigh 58 dimer acid modified epoxy resin, 128 epoxy resin 10, E-10P 5, polyether amine M600 12, propylene glycol methyl ether 15 in parts by weight.

[0065] Preparation of S01, A component:

[0066] S11. Stir the low-viscosity modified water-based epoxy resin, propylene glycol methyl ether, and dispersant at 400r / min for 20min, and mix evenly;

[0067] Wherein the low-viscosity modified wate...

Embodiment 2

[0079] A preparation method of low-VOC waterborne two-component epoxy zinc-rich paint, comprising the following steps:

[0080] S00, material preparation

[0081] Component A: Weigh low-viscosity modified water-based epoxy resin 11, propylene glycol methyl ether 1, 800-mesh zinc powder 81.5, dispersant VXW6208 1.2, filler 1250-mesh silicon micropowder 5, anti-settling agent CLAYTONE APA0.3;

[0082] Component B: weigh 37.5 parts by weight of water-based epoxy curing agent, 62 parts of deionized water, and 0.5 part of anti-flash rust agent;

[0083] Low-viscosity modified water-based epoxy resin: Weigh dimer acid modified epoxy 53, 128 epoxy resin 15, E-10P 5, polyetheramine M600 12, propylene glycol methyl ether 15 by weight.

[0084] Preparation of S01, A component:

[0085] S11. Stir the low-viscosity modified water-based epoxy resin, co-solvent, and dispersant at 400r / min for 20min, and mix well;

[0086] Wherein the low-viscosity modified waterborne epoxy resin is obtai...

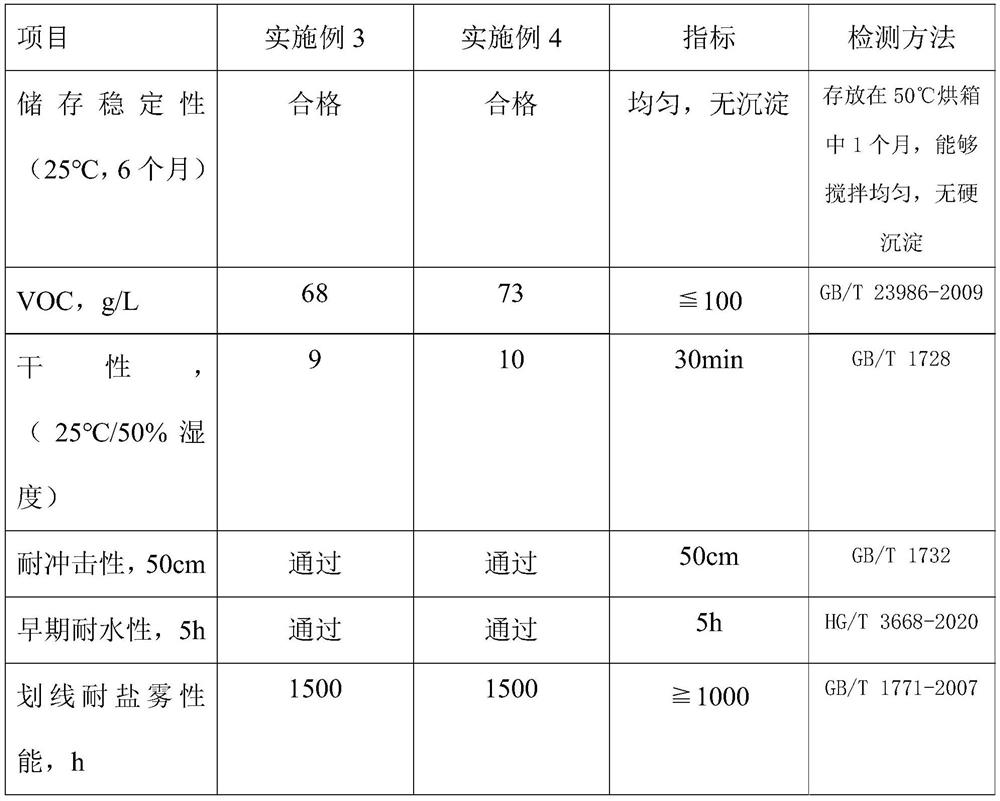

Embodiment 3

[0102] A preparation method of low-VOC waterborne two-component epoxy zinc-rich paint, comprising the following steps:

[0103] S00, material preparation

[0104] Component A: Weigh 12.5 parts by weight of low-viscosity modified water-based epoxy resin, 65 domestically produced Shenlong 500-mesh zinc powder, 20 filler barite powder, 1 propylene glycol ether as a cosolvent, 1 dispersant, and anti-sedimentation agent (Haiming Bentonite SD-2) 0.5;

[0105] Component B: weigh 37.5 parts by weight of water-based epoxy curing agent, 62 parts of deionized water, and 0.5 part of anti-flash rust agent;

[0106] Low-viscosity modified water-based epoxy resin: Weigh 55 modified epoxy resin, 128 epoxy resin 14, epoxy reactive diluent DER736 4, polyether amine M100012, propylene glycol methyl ether 15 by weight.

[0107] Preparation of S01, A component:

[0108] S11. Stir the low-viscosity modified water-based epoxy resin, co-solvent, and dispersant at 400r / min for 20min, and mix well; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com