Light steel framework sandwich heat-insulating concrete composite wall body formwork shell and preparation technique thereof

A technology for thermal insulation concrete and composite walls, which is applied in the direction of thermal insulation, walls, and building components. It can solve the problems of large water vapor evaporation, easy gaps, and poor cast-in-place quality, and achieve simple preparation effects, prevent water vapor transpiration, and use The effect of simple and convenient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

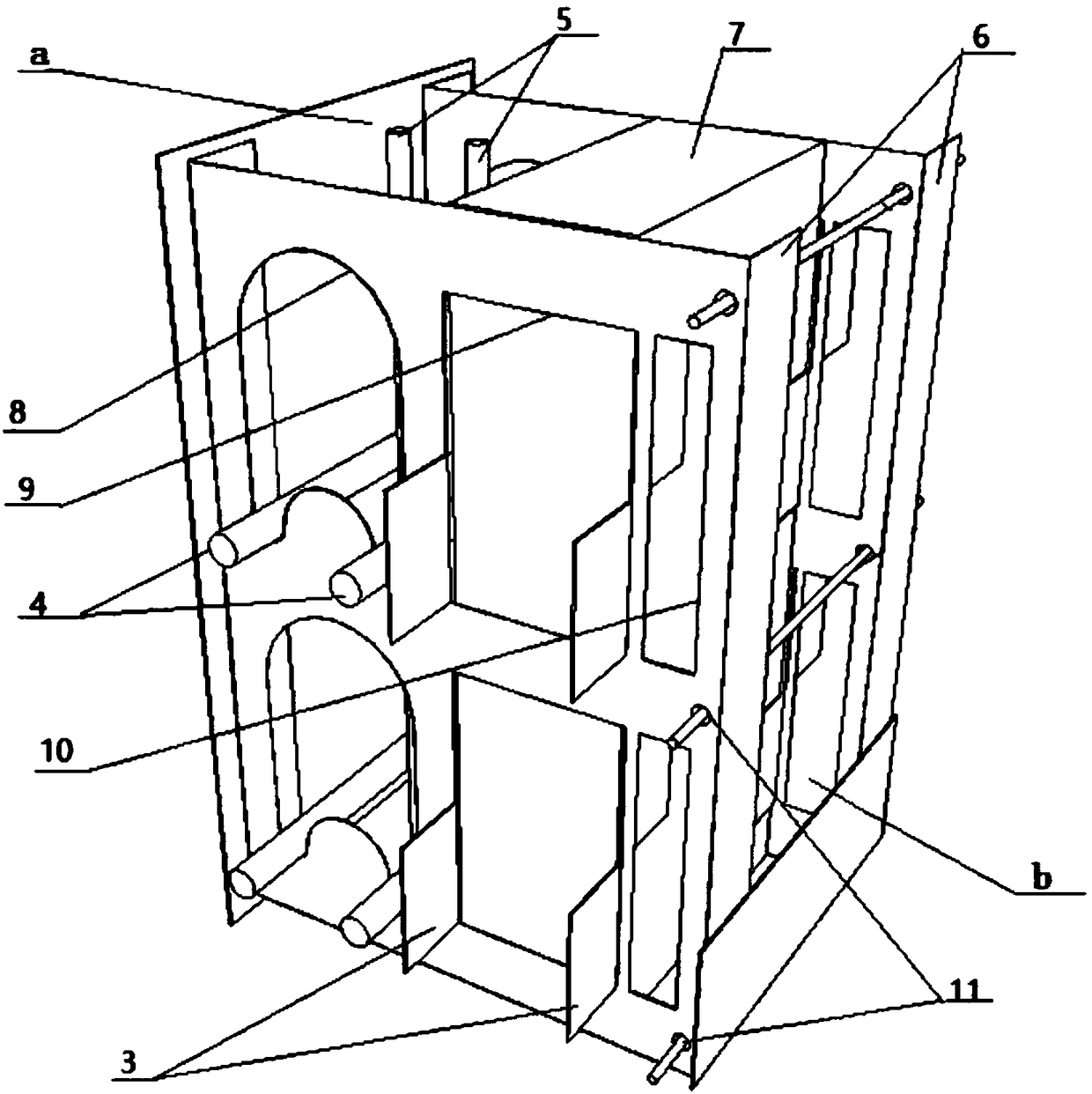

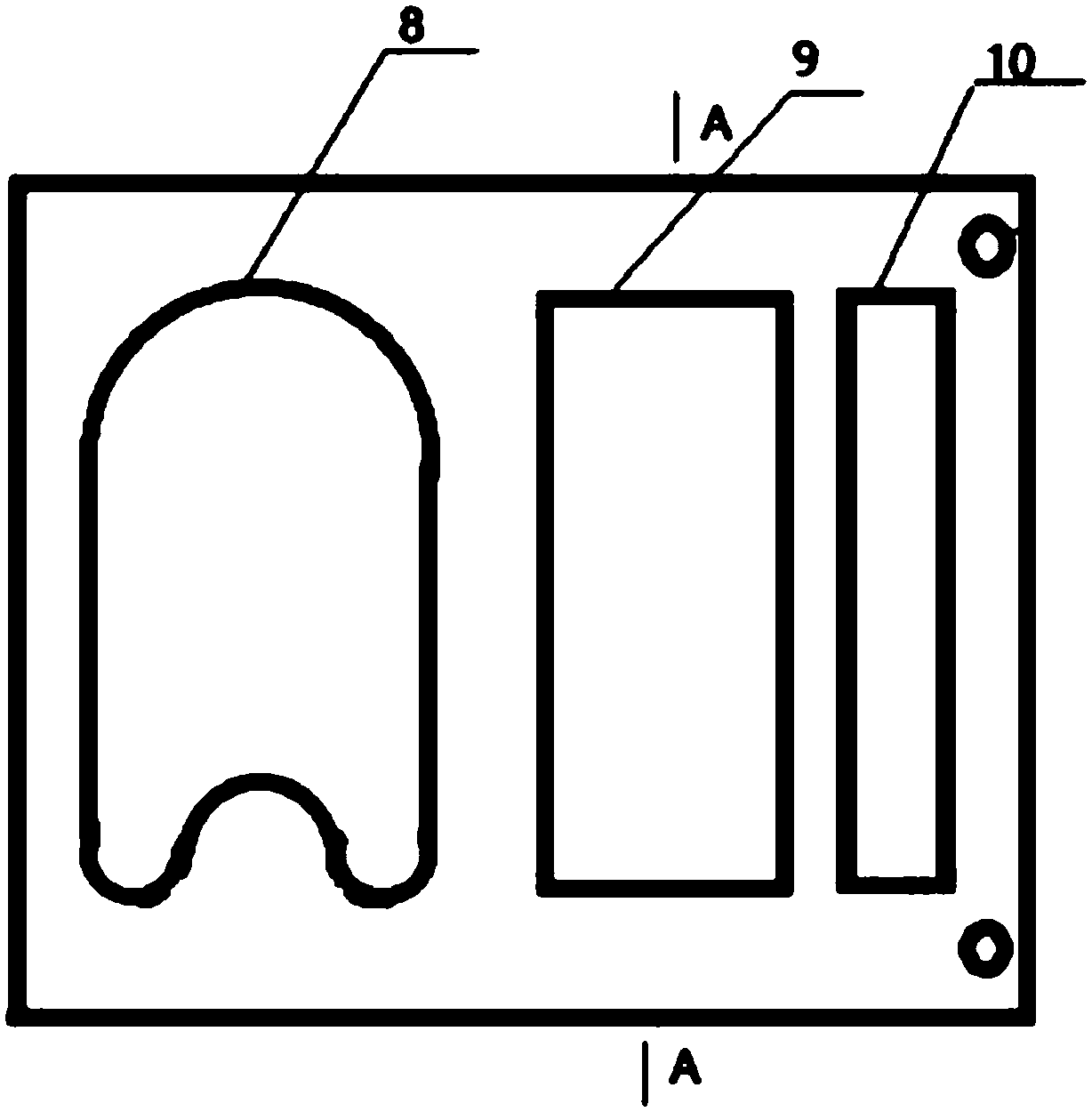

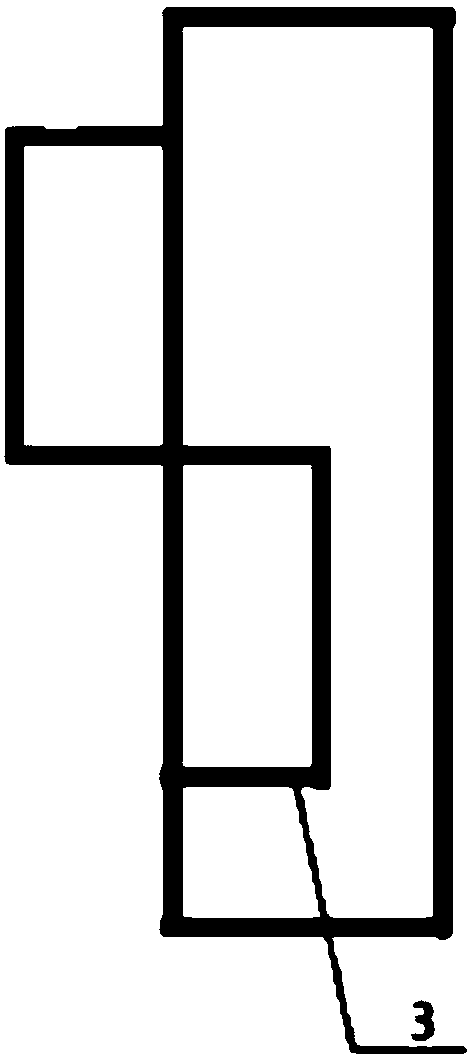

[0034] Embodiment 1, with reference to Figure 1-3 , a light steel skeleton sandwich thermal insulation concrete composite formwork, comprising a hollow formwork main body, an insulation laminate 7 is clamped in the inner cavity of the formwork main body, and the insulation laminate separates the inner cavity of the formwork main body from front to back into The load-bearing cavity a and the protective layer cavity b, the load-bearing cavity a and the protective layer cavity b are injected with concrete to form a load-bearing layer and a protective layer in one-to-one correspondence, and the load-bearing layer, the insulation layer plate 7, and the protective layer are formed side by side in sequence Composite walls. A reinforcement grid is provided in the load-bearing layer, and a plurality of transverse reinforcement bars 11 are arranged side by side in the protective layer, and both the reinforcement grid and the lateral reinforcement bars 11 are fixedly connected to the ma...

Embodiment 2

[0038] Embodiment 2, a preparation process for a formwork-free concrete wall, comprising the above-mentioned light steel skeleton sandwich insulation concrete composite wall formwork, which includes the following steps,

[0039] ① Configure concrete, configure the concrete raw materials to obtain high fluidity concrete;

[0040] ② Set up the sandwich, select multiple wall formwork shells and insert the insulation laminate 7 into each wall formwork shell, insert a tensile steel bar 4 into each arched groove, and pass through the load-bearing cavity. Insert the anti-seismic steel bar 5, the tensile steel bar 4 and the anti-seismic steel bar 5 are wound to form a steel bar grid, and penetrate the fixed transverse steel bar in the protective layer cavity;

[0041] ③Fix the mould, arrange multiple wall formworks in the horizontal direction, and the front and back adjacent wall formworks are nested and docked by folding to form a continuous wall skeleton, so that the load-bearing ca...

Embodiment 3

[0043] Embodiment 3, a preparation process of a formwork-free concrete wall, comprising the above-mentioned light steel skeleton sandwich insulation concrete composite wall formwork, which includes the following steps,

[0044] ① Configure concrete, configure the concrete raw materials to obtain high fluidity concrete;

[0045] ② Set up the sandwich, select multiple wall formwork shells and insert the insulation laminate 7 into each wall formwork shell, insert a tensile steel bar 4 into each arched groove, and pass through the load-bearing cavity. Insert the anti-seismic steel bar 5, the tensile steel bar 4 and the anti-seismic steel bar 5 are wound to form a steel bar grid, and penetrate the fixed transverse steel bar in the protective layer cavity;

[0046] ③Fix the mould, arrange multiple wall formworks in the horizontal direction, and the front and back adjacent wall formworks are nested and docked by folding to form a continuous wall skeleton, so that the load-bearing cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com