High-power beam trap

A high-power, reflective surface technology, used in instruments, laser welding equipment, optics, etc., can solve the problem of expensive assembly and achieve high absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

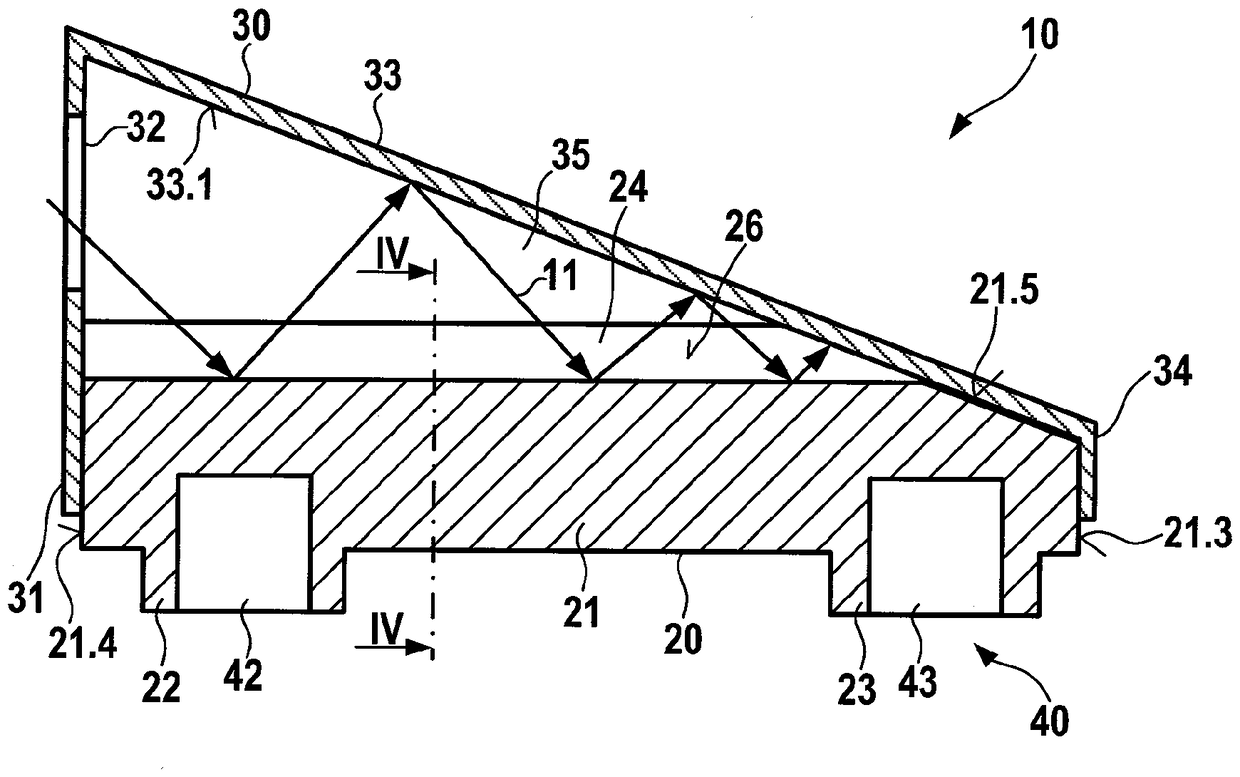

[0025] figure 1 The high power beam trap 10 according to the invention is shown in a side sectional view. It has an absorber 20 which is covered by a housing 30 .

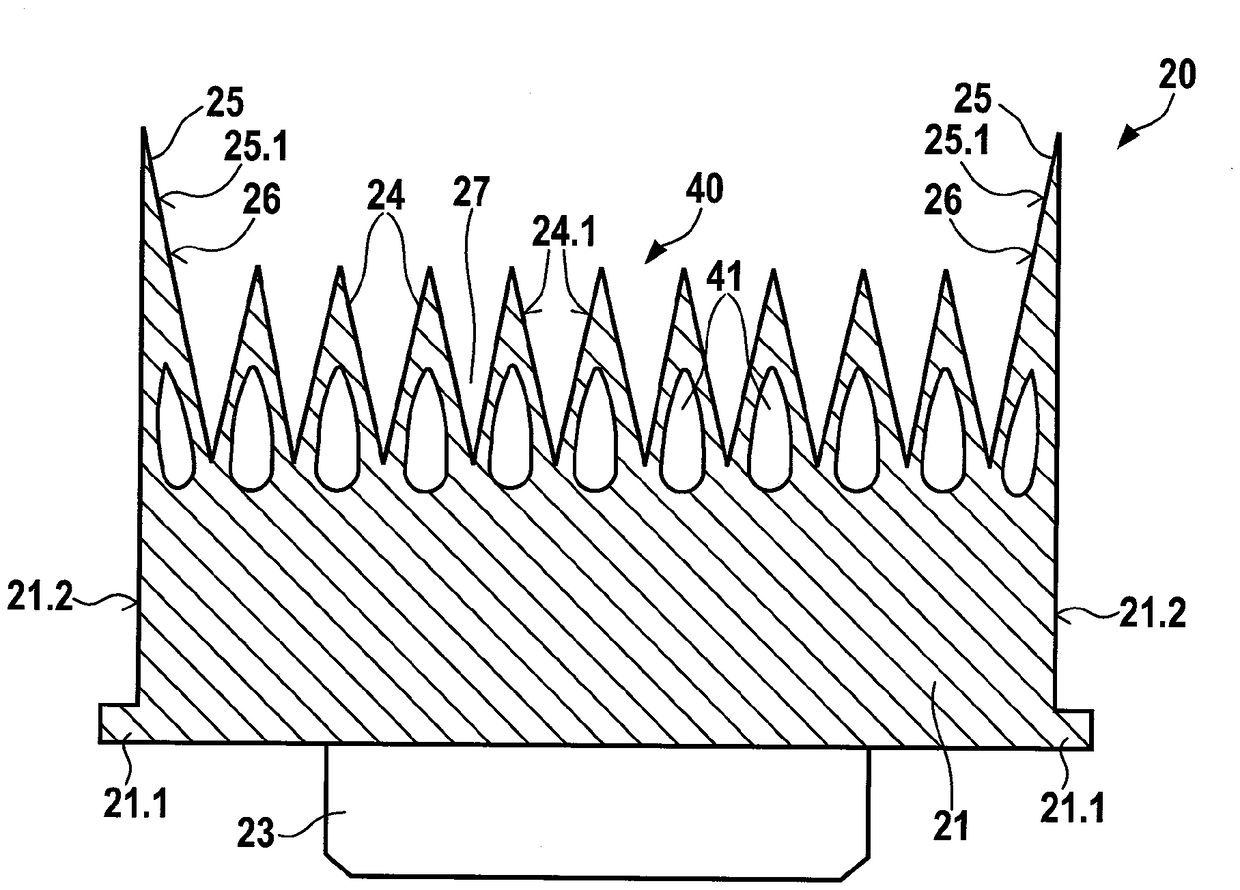

[0026] The absorbent body 20 has a base body 21 on which wedge-shaped ribs 24 are molded, as from figure 2 can be found in more detail. The surface of the wedge-shaped ribs 24 forms the absorption surface 26 . Opposite the wedge-shaped ribs 24 , an inlet connection 22 and an outlet connection 23 are formed on the base body 21 . The inlet connecting pipe 22 forms the coolant inlet 42 and the outlet connecting pipe 23 forms the coolant outlet 43 of the cooling circuit 40 .

[0027] The housing 30 covers the absorber 20 on the sides of the wedge-shaped ribs 24 . Housing cover 33 of housing 30 is oriented obliquely to absorption surface 26 . Facing the wedge-shaped rib 24, it forms the reflective surface 33.1. The front side 31 , the housing closure 34 and the two opposite side walls 35 extend from the housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com