Battery Formation Equipment

A technology for battery formation and equipment, applied in secondary batteries, secondary battery manufacturing, electrochemical generators, etc., can solve problems such as reducing the working efficiency of transfer batteries, affecting the normal service life of batteries, and inconsistent battery charging time, and achieving convenient Recycle the battery box, avoid falling directly into the conveyor belt, and avoid the effect of inconsistent charging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Further detailed explanation through specific implementation mode below:

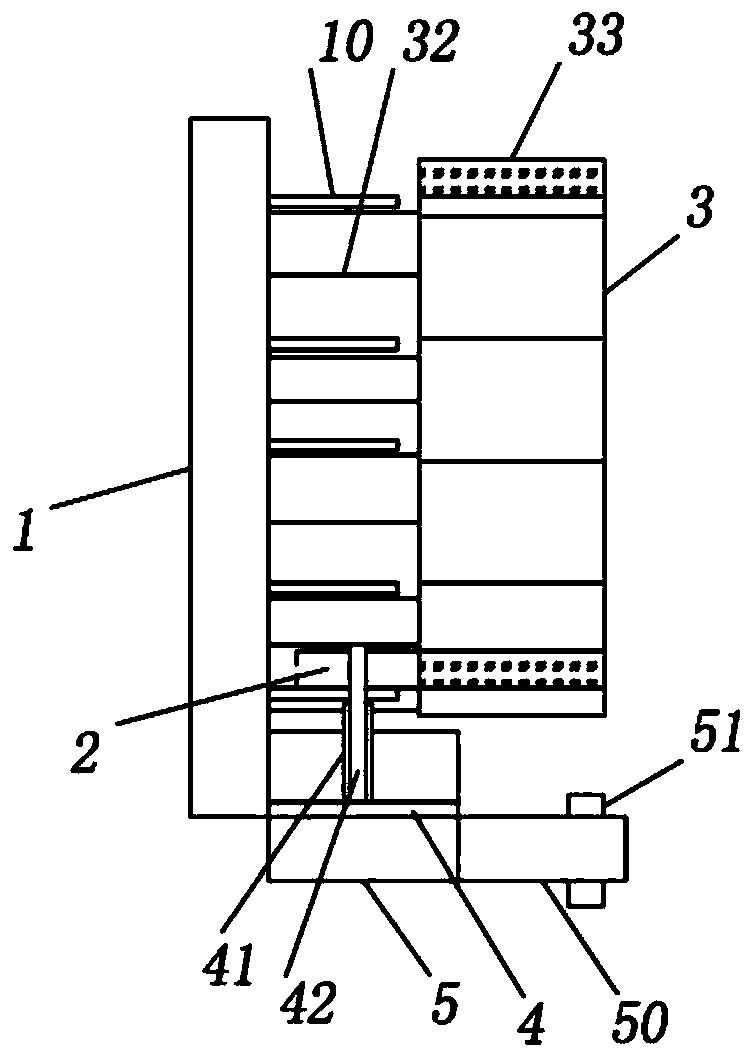

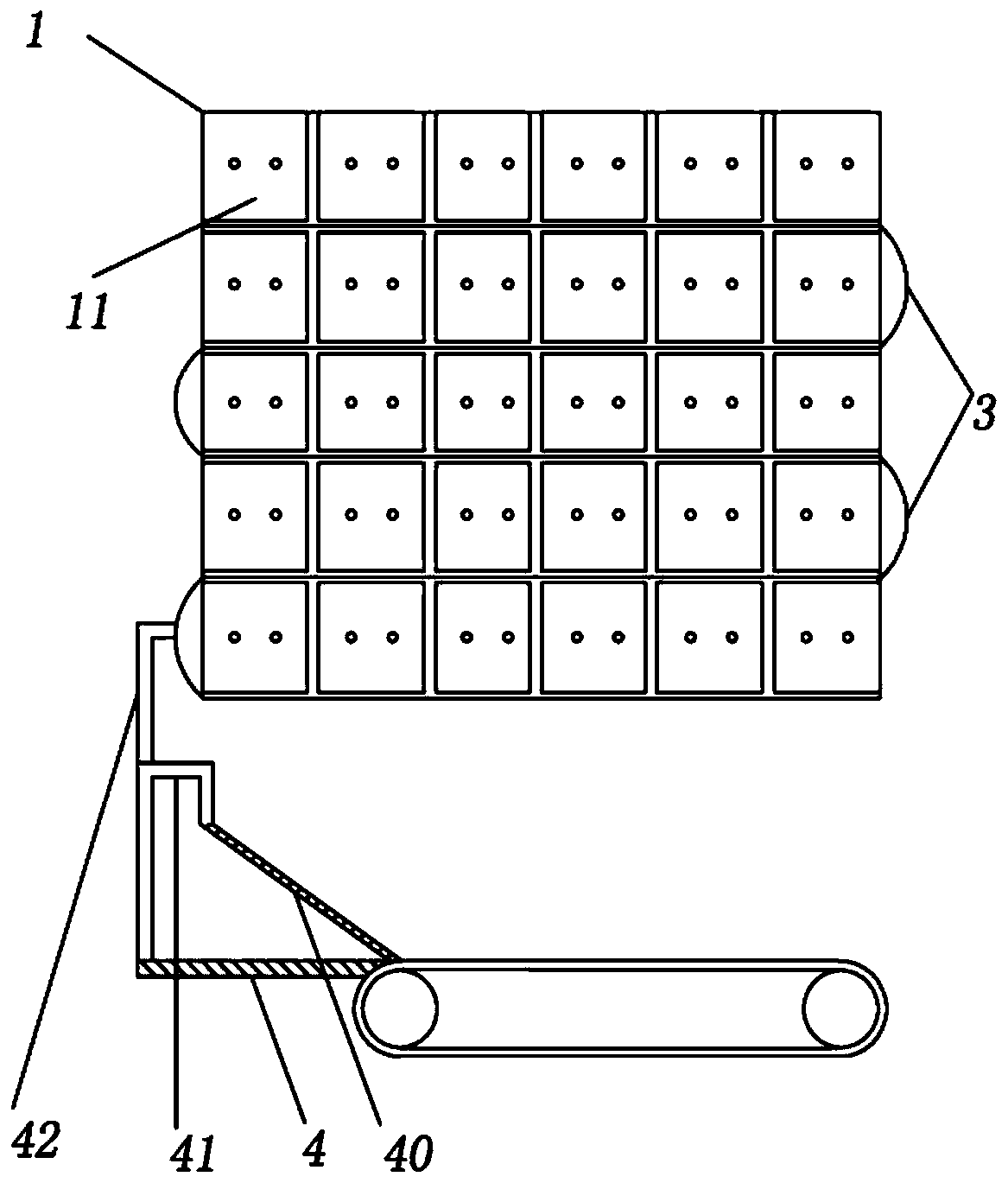

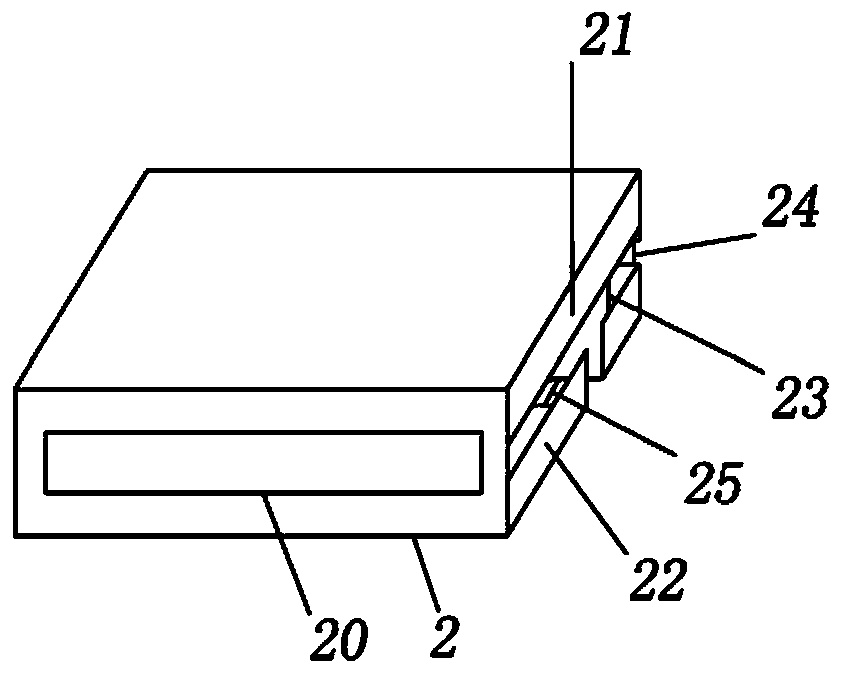

[0025] The reference signs in the drawings of the description include: body 1, skateboard 10, charging chamber 11, battery box 2, magnet 20, upper block 21, lower block 22, movable seam 23, U-shaped opening 24, strip seam 25. Circulation sleeve 3, horizontal transmission roller 30, steering transmission roller 31, rotating shaft 32, electromagnet 33, base plate 4, guide plate 40, ejector rod 41, support rod 410, horizontal shaft rod 411, ejector rod 412, blocking Bar 42, battery conveyor belt 5, battery box conveyor belt 50, electromagnet two 51.

[0026] The embodiment is basically as figure 1 Shown: battery formation equipment, including a body 1, a conveyor belt, a conveying mechanism, a transfer mechanism and several battery boxes 2. Such as figure 2 As shown, the fuselage 1 is provided with several charging chambers 11 distributed in rows and columns, and one charging chamber 11 correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com