Non-spark three-phase four-pole explosion-proof socket

A spark-type, three-phase electrode technology, applied to the base/housing, two-part connection device, electrical components, etc., can solve the problems of low automation, large amount of electrical connectors, and potential safety hazards of electrical equipment grounding failure, and achieve overall Reasonable structure setting, good sealing and insulation, good overall sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

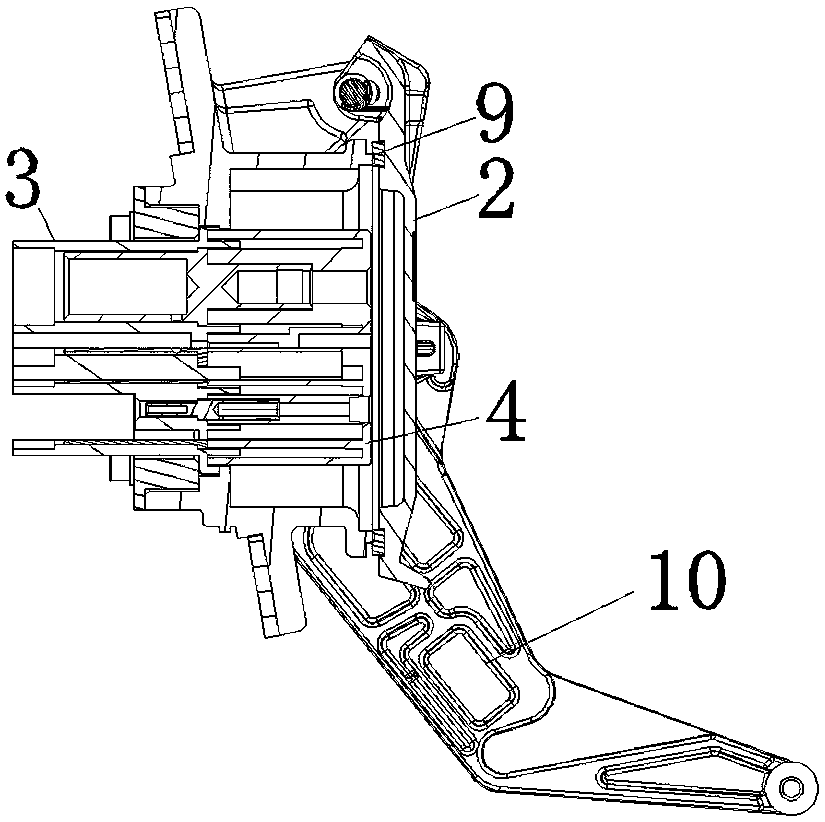

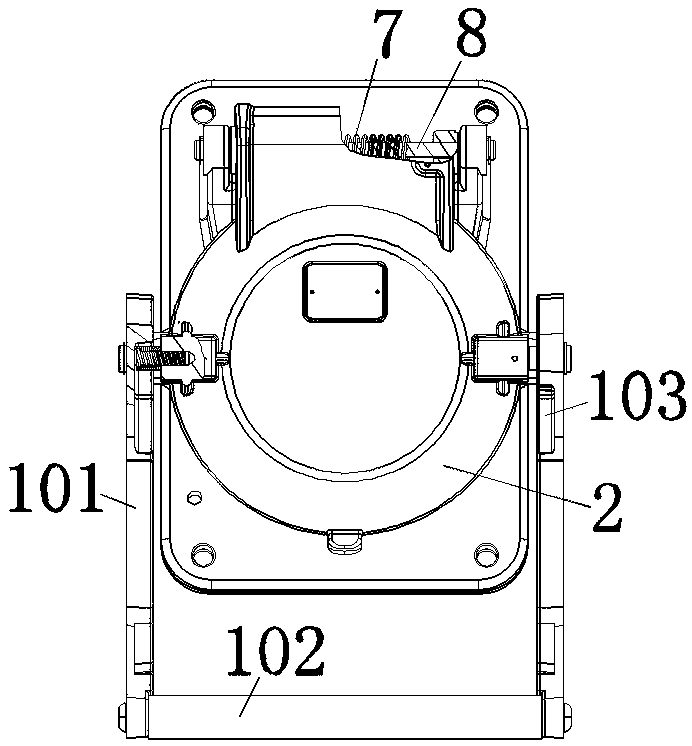

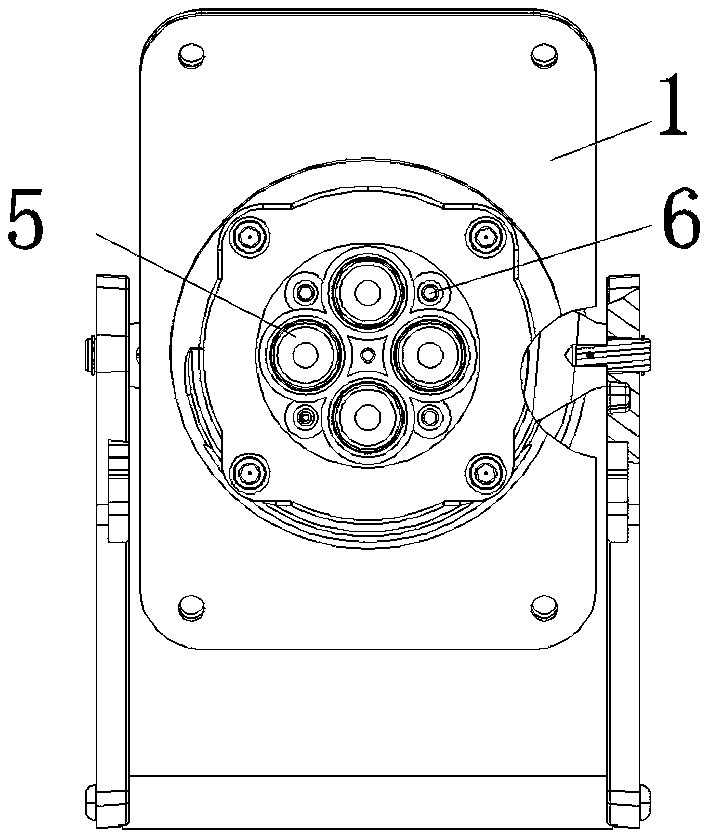

[0015] Embodiment: non-sparking type three-phase four-pole explosion-proof socket, including socket base, socket inner core, socket cover; Cover, the lower cover of the socket inner core is provided with a socket, and the upper cover of the socket inner core is provided with a three-phase electrode head socket and an auxiliary socket; the socket cover is connected with the socket seat through a torsion spring and a socket shaft, and at their connection The inner side of the socket cover is provided with a socket cover sealing ring; the outer side of the socket cover is provided with a push handle device.

[0016] The push handle device includes side push plates connected to both sides of the socket cover, a handle is provided between the side push plates; a connection notch is provided on the inner side of the upper part of the side push plate.

[0017] The socket seat and the socket cover are all made of cast aluminum alloy by die-casting, and the total content of magnesium a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com