Constant-resistance pneumatic box

A force pneumatic box and resistance technology, applied in the field of constant resistance pneumatic box, can solve problems affecting training effect, impact injury of joints and connective tissue, etc., and achieve the effect of high compensation precision and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that components in the various figures may be shown exaggerated for the purpose of illustration and are not necessarily true to scale. In the various figures, identical or functionally identical components are assigned the same reference symbols.

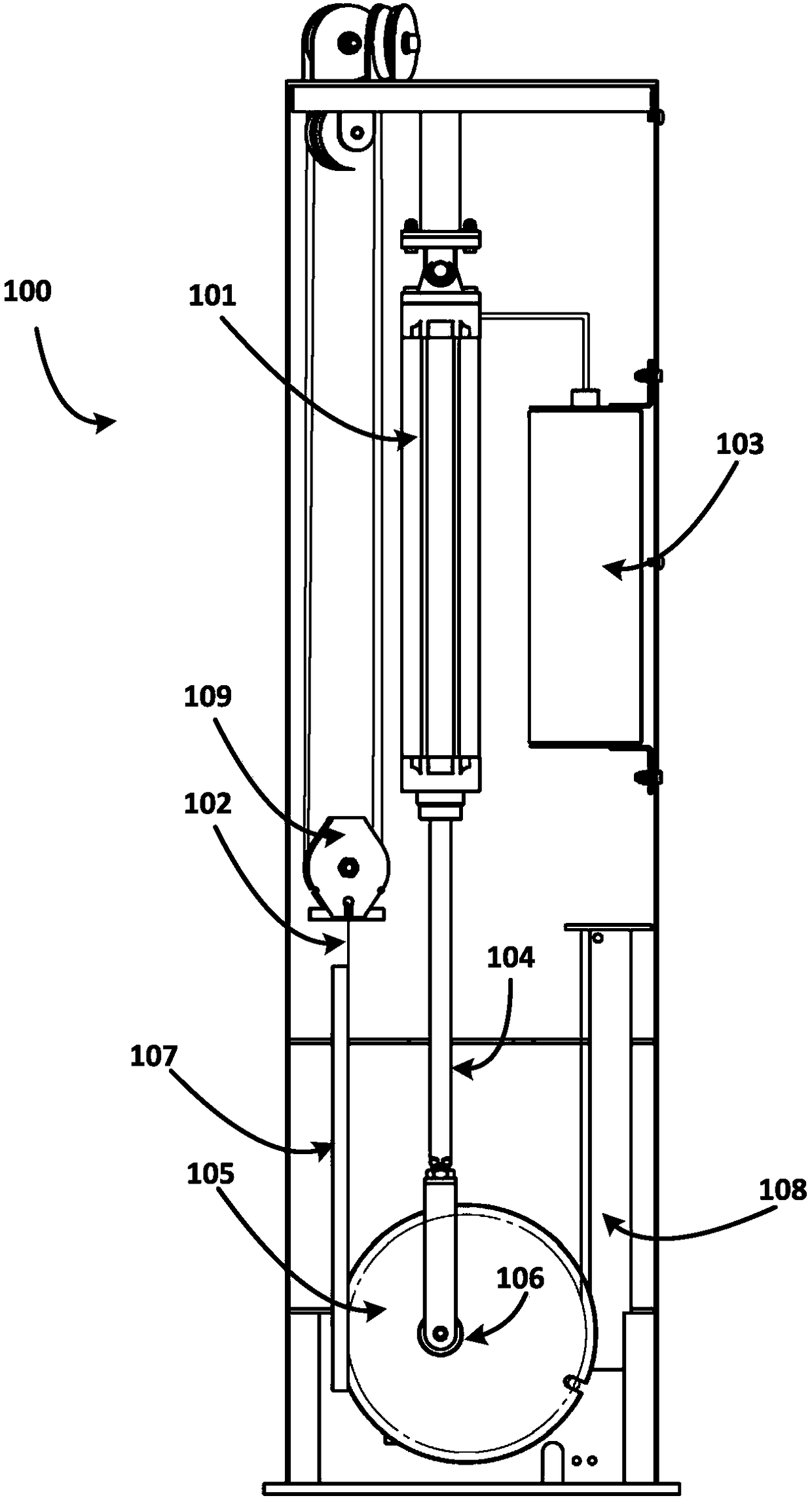

[0029] figure 1 A schematic diagram of a constant resistance aerodynamic box 100 according to the present invention is shown.

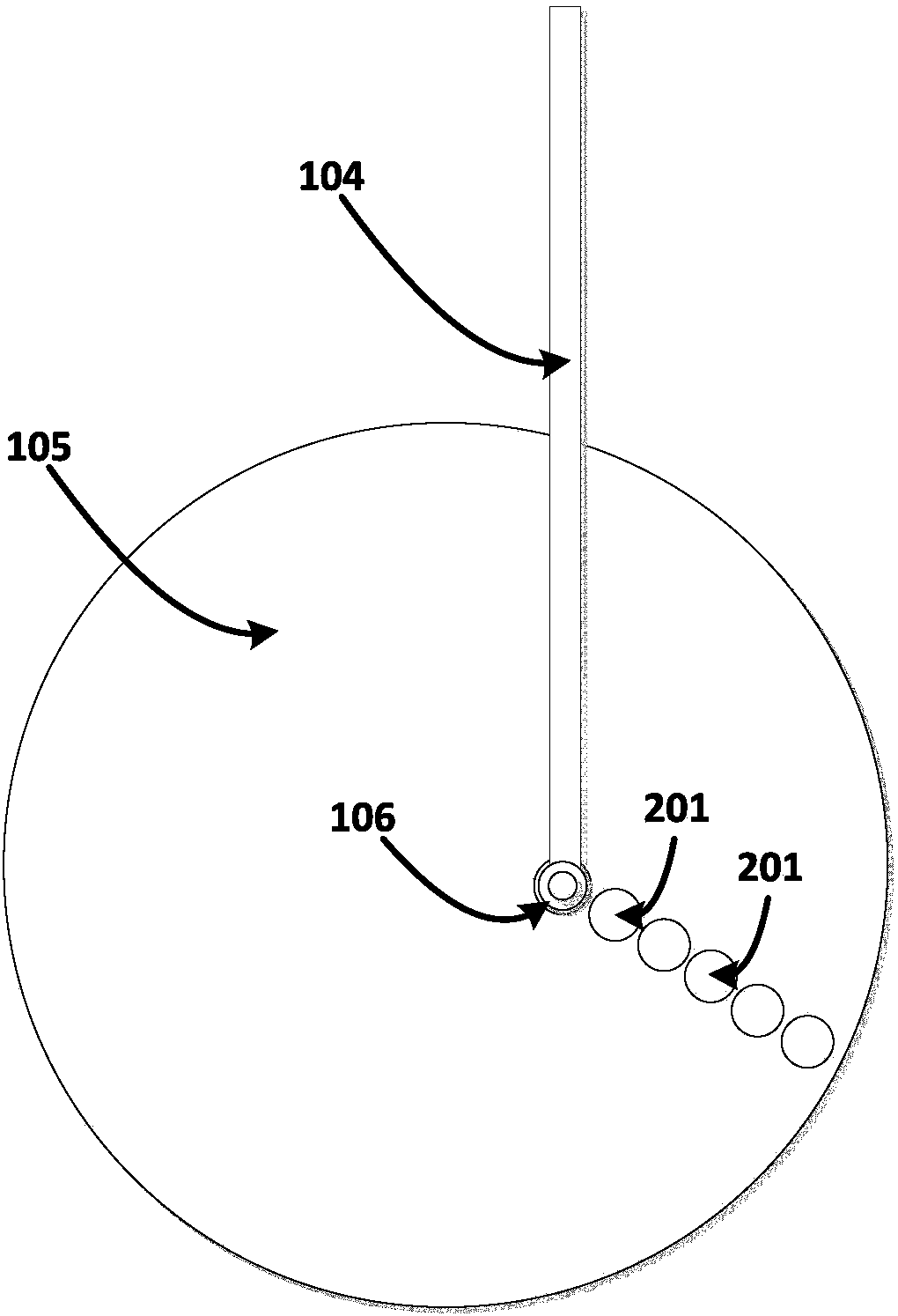

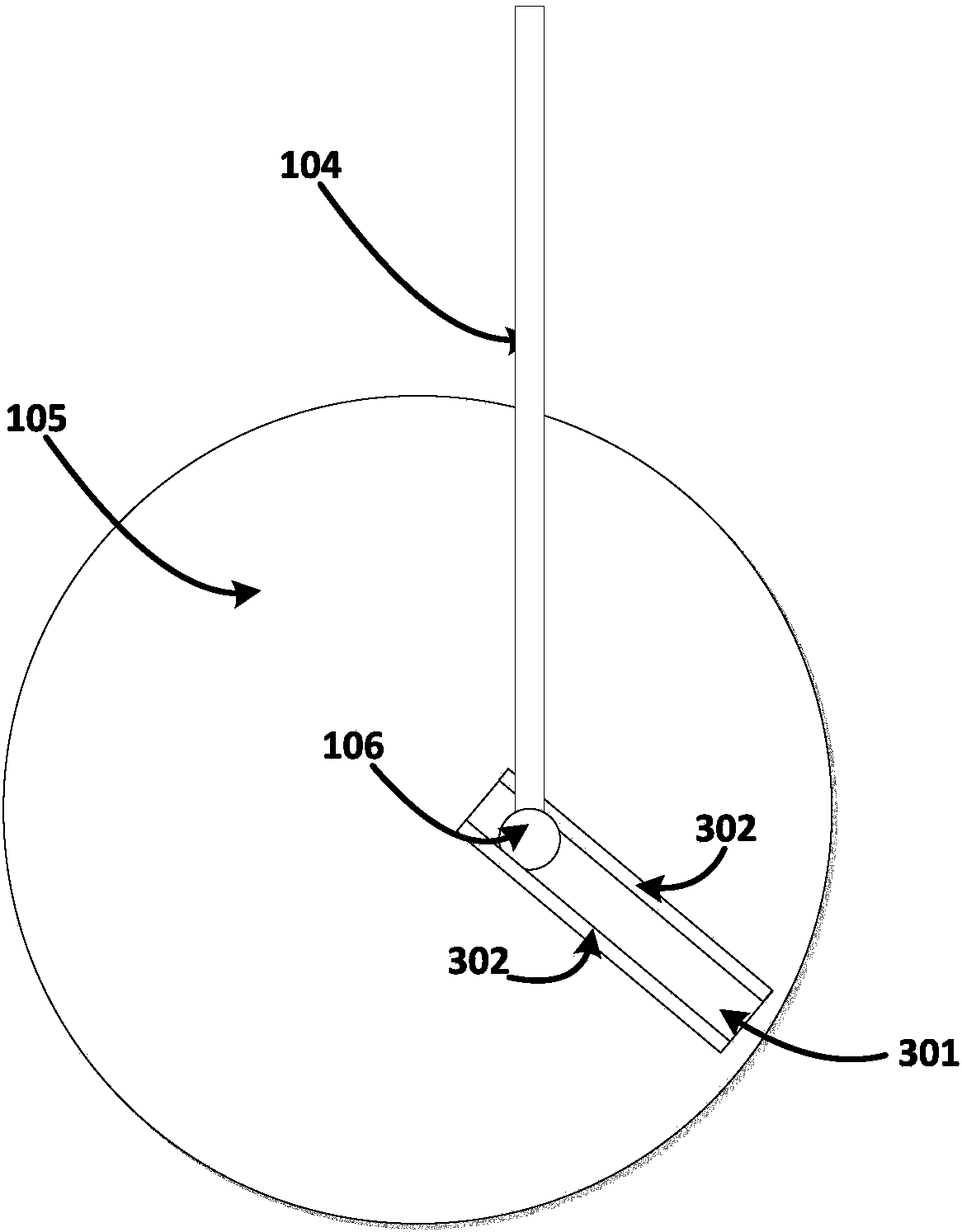

[0030] Such as figure 1 As shown, the constant resistance pneumatic box 100 includes an air cylinder 101 . The cylinder 101 includes a piston (not shown) and a piston rod 104, wherein the cylinder 100 is fixed so that it can rotate at a certain angle (such as 30°, 45° or 90°). exist figure 1 In , the cylinder 101 is shown with one end fixed to the housing by a rotating shaft so that it can rotate. However, other rotational attachments are also conceivable, for example the cylinder is attached rotatably in its middle to the housing. One end of the piston rod 104 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com