Double-station intelligent light inspection system and method

A smart light, double-station technology, applied in sorting and other directions, can solve the problems of being easily affected by external light, poor image acquisition accuracy, unstable equipment operation, etc., to achieve compact structure, stable equipment operation, and reduced labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

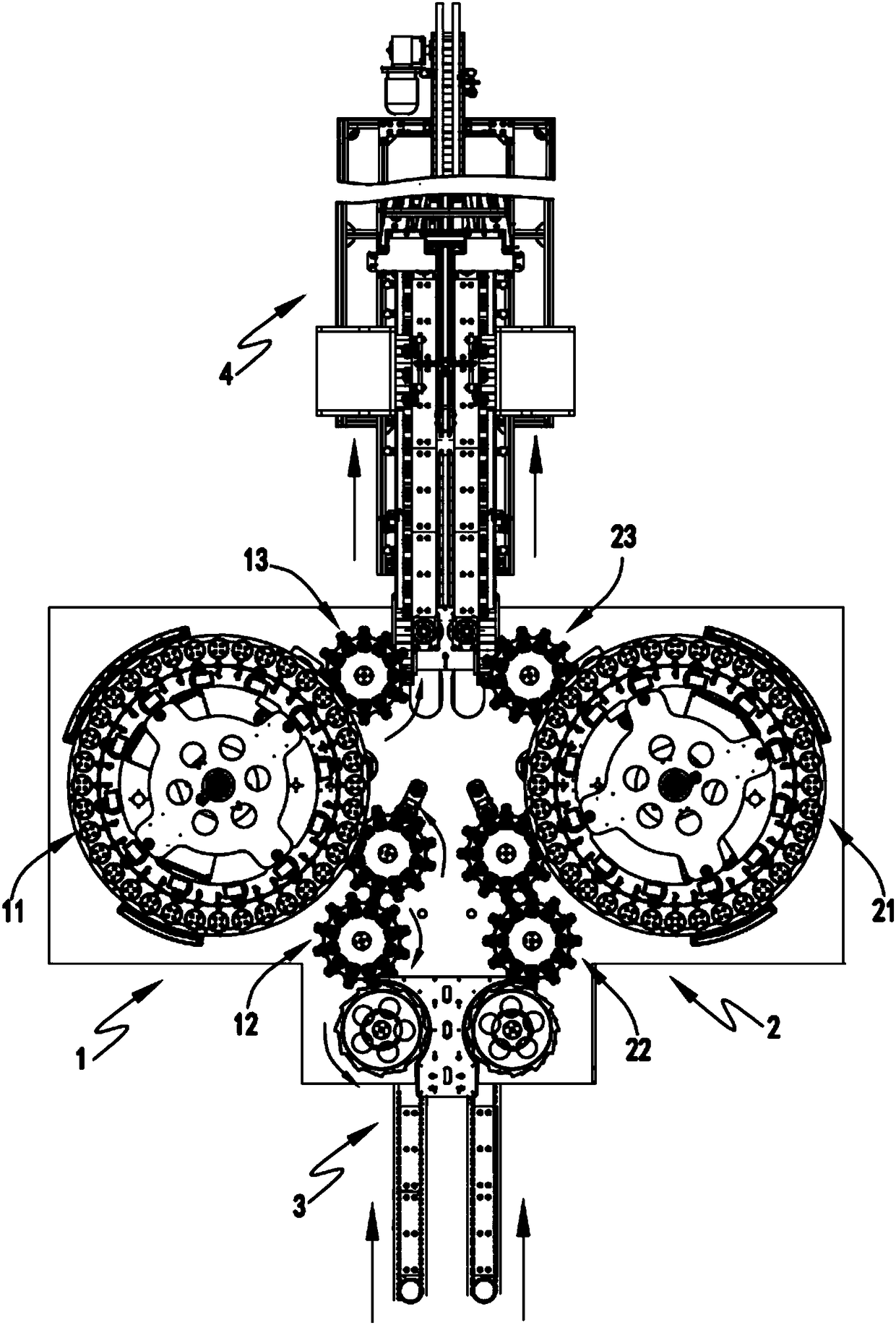

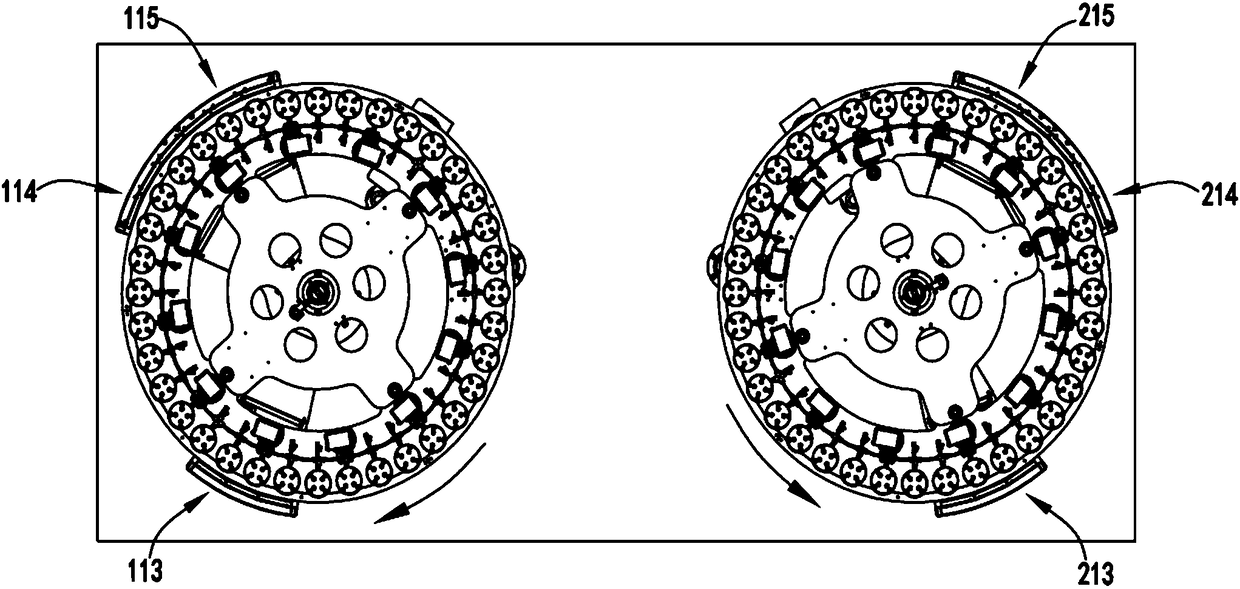

[0069] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 As shown, a double-station intelligent light inspection system includes a light inspection line a1 and a light inspection line b2. The light inspection line a1 includes a light inspection device a11, and is used to transfer bottles at the entrance of the light inspection device a11. The transfer-in device a12 to the light inspection device a11 and the transfer-out device a13 arranged at the exit of the light inspection device a11 for transferring the bottle out of the light inspection device a11, the lamp inspection device a11 includes a grasping mechanism a111 , the driving mechanism a112 fixedly connected with the grasping mechanism a111 and driving the grasping mechanism a111 to rotate together with the bottle body grasped by it, and the liquid detection mechanism a113 arranged in sequence along the circular motion track of the grasping mechanism a111 fr...

Embodiment 2

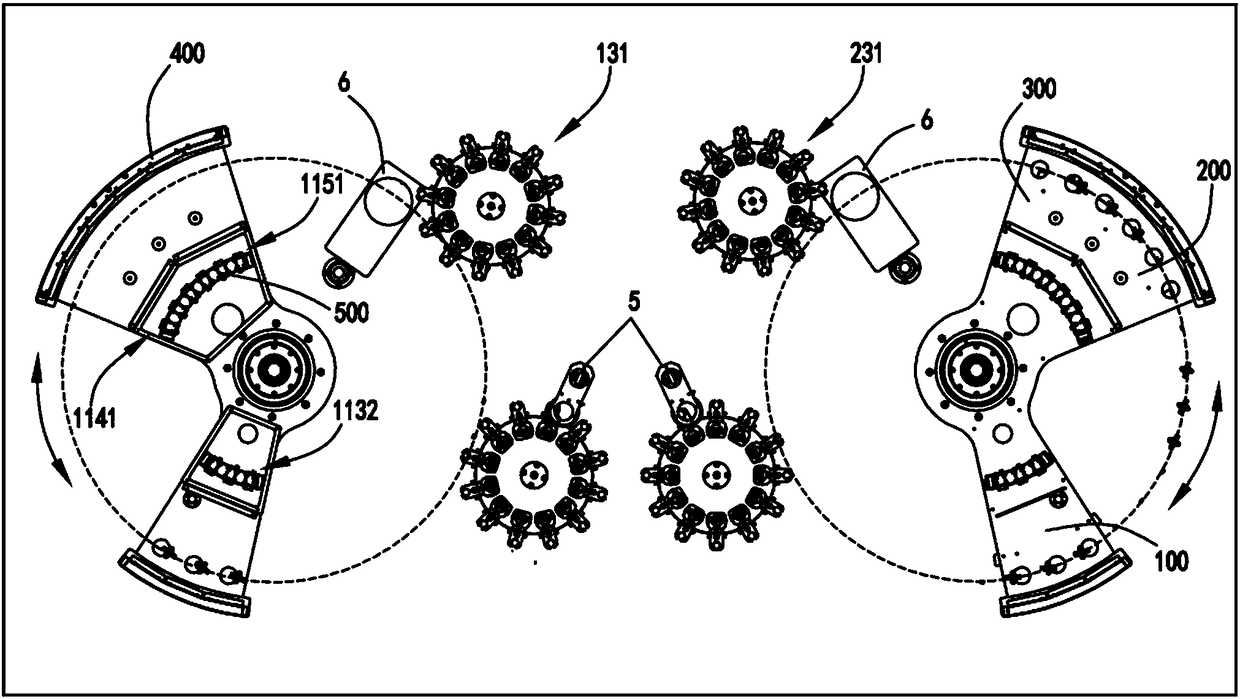

[0095] like figure 2 and Figure 8 , wherein the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between the second embodiment and the first embodiment is: further, the rotary assembly 1131 includes a rotating part b1133, a driven part b1134 matched with the rotating part b1133, and a support part 1135 fixed on the driven part b1134, The rotating part b1133 drives the driven part b1134 together with the supporting part 1135 to rotate forward and backward around the main shaft 1121. The supporting part 1135 includes the first installation part 100 for installing the liquid image acquisition assembly a1132, which is used for installing the liquid image acquisition assembly The second installation part 200 of b1141 and the third installation part 300 for installing the bottle body image acquisition asse...

Embodiment 3

[0099] like Figure 14As shown, a double-station intelligent light inspection method includes the following production steps:

[0100] a. In the feeding process, the bottles to be detected are transported through the feeding belt 31 and the bottles are transported backwards at equal intervals through the bottle pulling mechanism;

[0101] b. Transfer-in process, the transfer-in device located at the transfer-in station fixes the bottle conveyed in step a by clamping the neck of the bottle and uses circular motion to drive it to transfer backward;

[0102] c. bottle cap detection process, during the transfer of the bottle at the transfer station, the bottle cap image acquisition component 5 located above the transfer station carries out graphics acquisition for the bottle cap of the bottle;

[0103] d. Liquid detection process, the bottle that has completed the bottle cap detection in step c is transferred to the light inspection device and continues to make a circular motion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com