Small aero-engine hydraulic assembling frame

An aero-engine and small-scale technology, which is applied in the field of aviation manufacturing engineering, can solve problems such as parts assembly and disassembly operations, and achieve the effects of ensuring safety, improving stability, and improving power efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below, referring to the accompanying drawings.

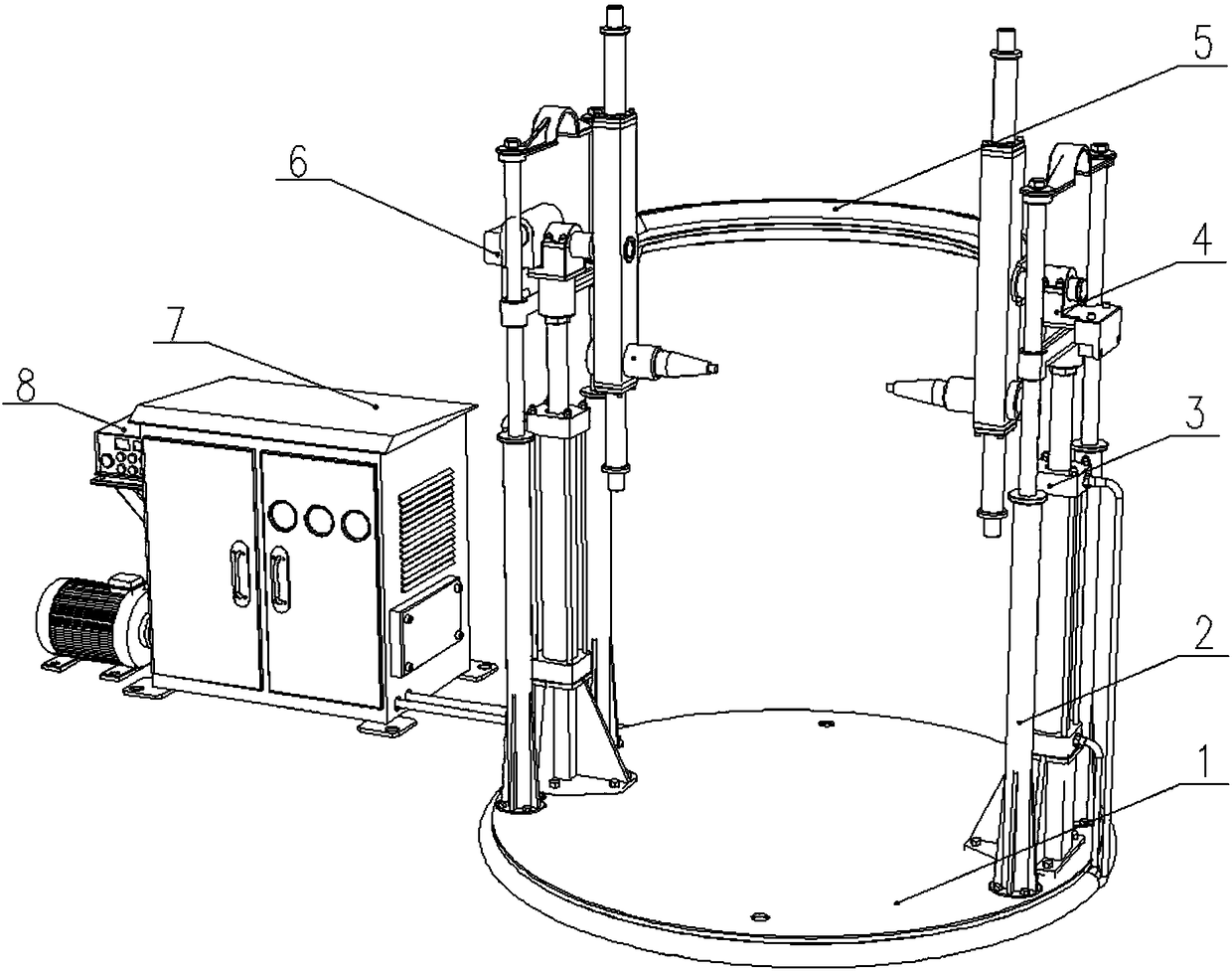

[0019] A hydraulic assembly frame for a small aero engine, including a bottom round platform (1), a limit sliding rod mechanism (2), a hydraulic cylinder mechanism (3), a lifting platform mechanism (4), a turning support mechanism (5), and a reducer motor (6), hydraulic system integration box (7), controller (8), etc.

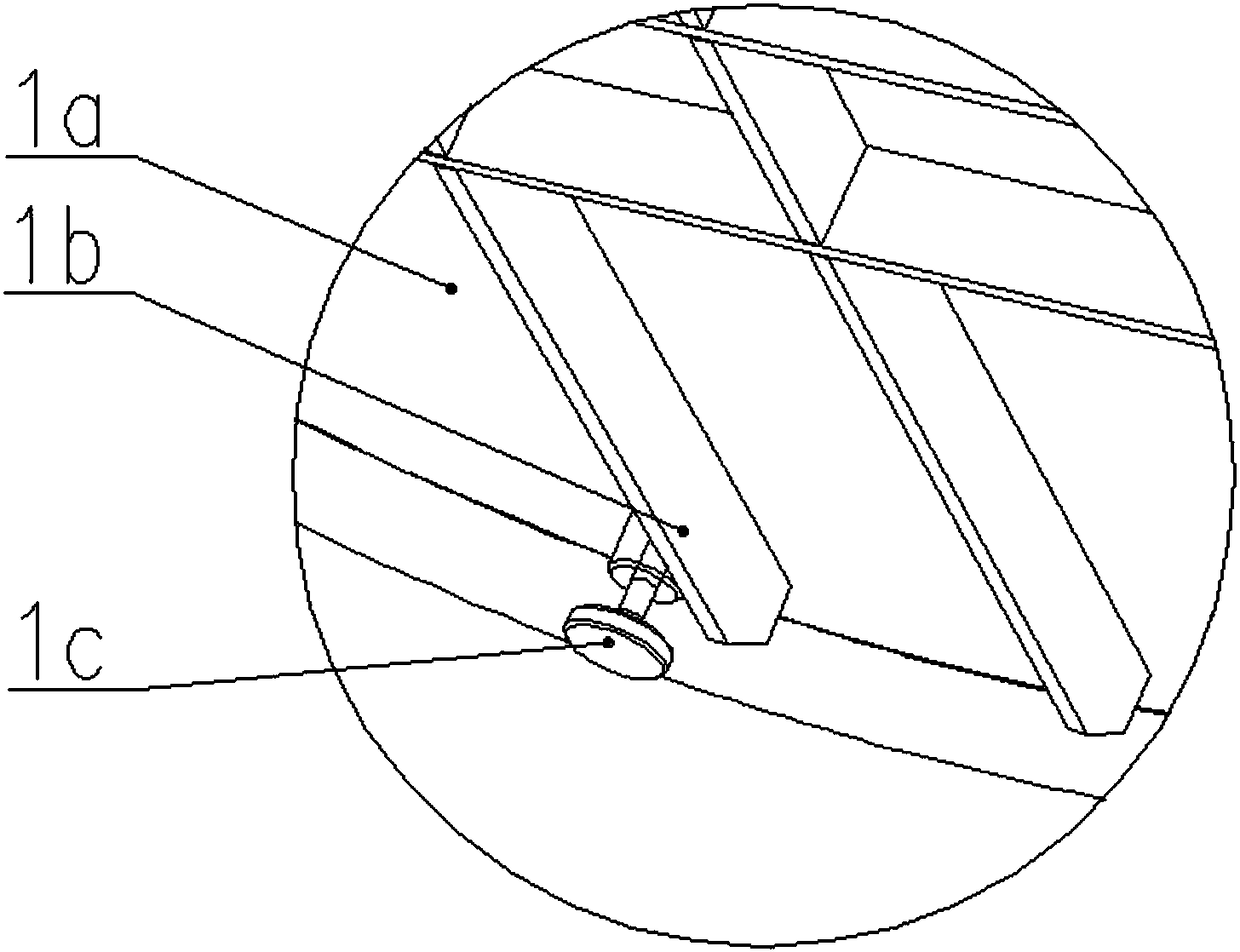

[0020] The main body of the bottom round platform (1) is a circular platform (1a), under the circular platform (1a) there are welded warp and weft interlaced reinforcing ribs (1b), and 4 are installed symmetrically on the bottom edge of the circular platform (1a). ~ 8 sets of rollers and screw support blocks (1c).

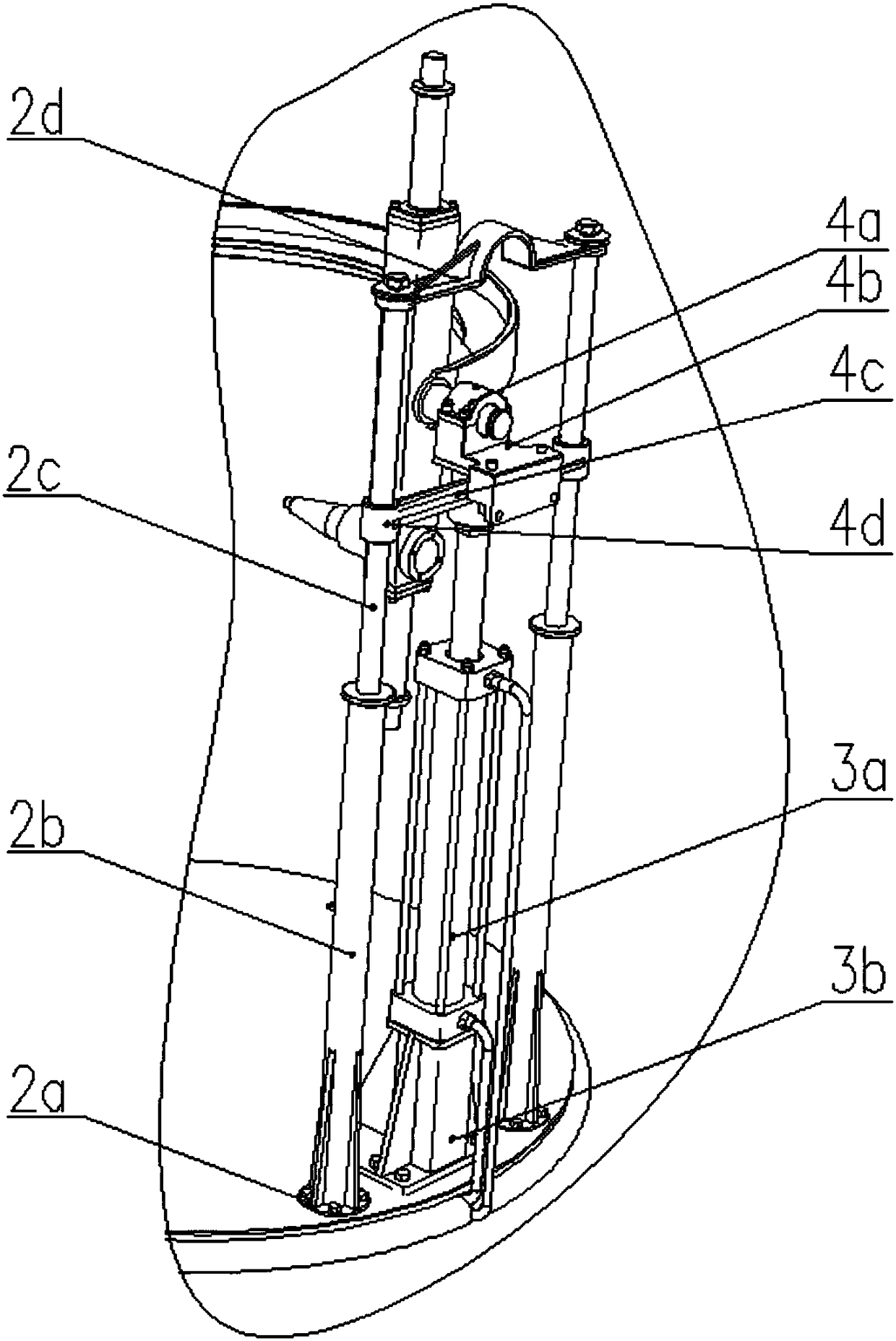

[0021] The limit sliding rod mechanism (2) is divided into two groups, left and right, each group consists of 2 flanges (2a), 2 support rods (2b), 2 polished rods (2c), and 1 seal. The cover (2d) is composed of connecting bolts; among them, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com