Method for raising carburant absorptivity in cast iron synthesis technology

A technology for synthesizing cast iron and recarburizer, applied in the field of cast iron production, can solve the problem of low absorption rate of recarburizer, and achieve the effects of shortening the absorption time, increasing the absorption rate, and improving the water yield of scrap steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

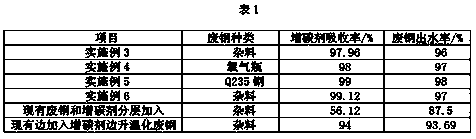

Examples

Embodiment 1

[0010] Embodiment 1: The method for improving the absorption rate of the recarburizer in the synthetic cast iron process is carried out as follows: the recarburizer is laid on the inner bottom of the equipment, and then the molten iron formed by scrap steel is washed into the bottom to lay the recarburizer Inside the equipment, the temperature of molten iron formed from steel scrap is 1450°C to 1550°C. After the molten iron formed from steel scrap is washed in, the molten iron formed from steel scrap absorbs the recarburizer to obtain carburized molten iron. The time for the molten iron formed from steel scrap to absorb the recarburizer is 1 minutes to 2 minutes.

[0011] The present invention adopts a carburant adding method different from the prior art, and adopts a bottom filling method (the carburant is placed on the bottom of the equipment, and then the molten iron formed from scrap steel is washed into the equipment at the bottom where the carburant is placed. ) to impro...

Embodiment 2

[0014] Example 2: As an optimization of the above example, the molten iron formed from scrap steel is obtained by the following method: melting scrap steel into molten iron, removing impurities on the surface of the molten iron, and heating the molten iron after removing impurities to 1450°C to 1550°C to obtain scrap steel into molten iron of molten iron.

Embodiment 3

[0015] Embodiment 3: The method for improving the absorption rate of recarburizer in the synthetic cast iron process is carried out as follows: the recarburizer is laid on the inner bottom of the equipment, and then the molten iron formed by scrap steel is washed into the bottom to lay the recarburizer Inside the equipment, the temperature of molten iron formed from steel scrap is 1450°C. After the molten iron formed from steel scrap is washed in, the molten iron formed from steel scrap absorbs the recarburizer to obtain carburized molten iron. The time for the molten iron formed from steel scrap to absorb the recarburizer is 2 minutes.

[0016] By adopting the method described in Example 3, the absorption rate of the carburant by molten iron can reach 97.96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com