Prefabricated corrugated steel concrete composite pipe gallery

A comprehensive pipe gallery and concrete technology, which is applied in construction, artificial islands, infrastructure engineering, etc., can solve the problems of long construction time and heavy workload, and achieve the effect of large effective use of space, light weight, and guaranteed production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

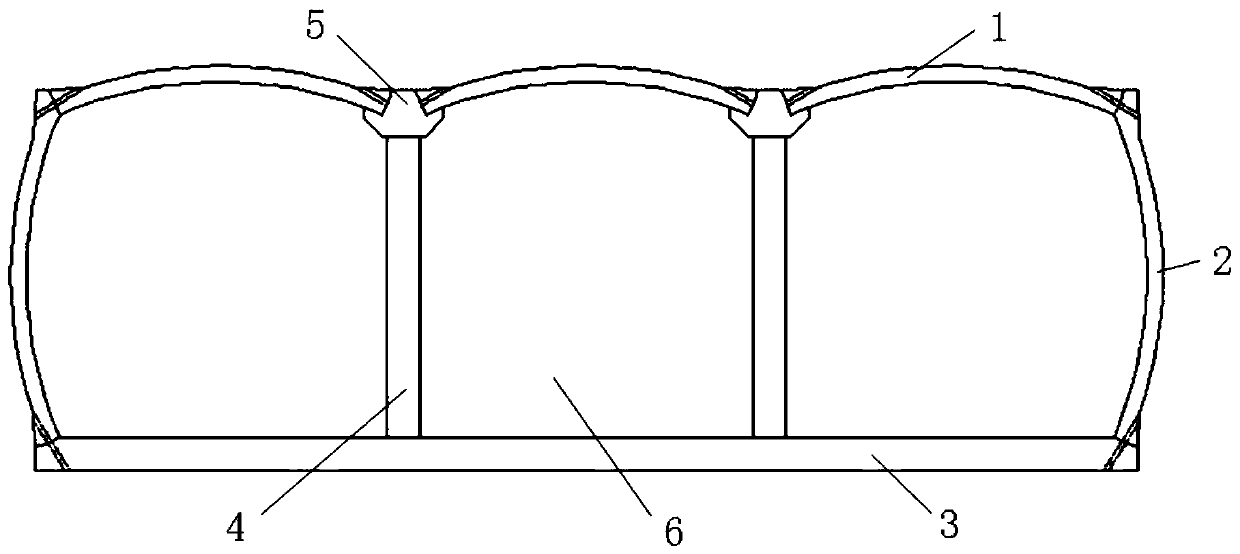

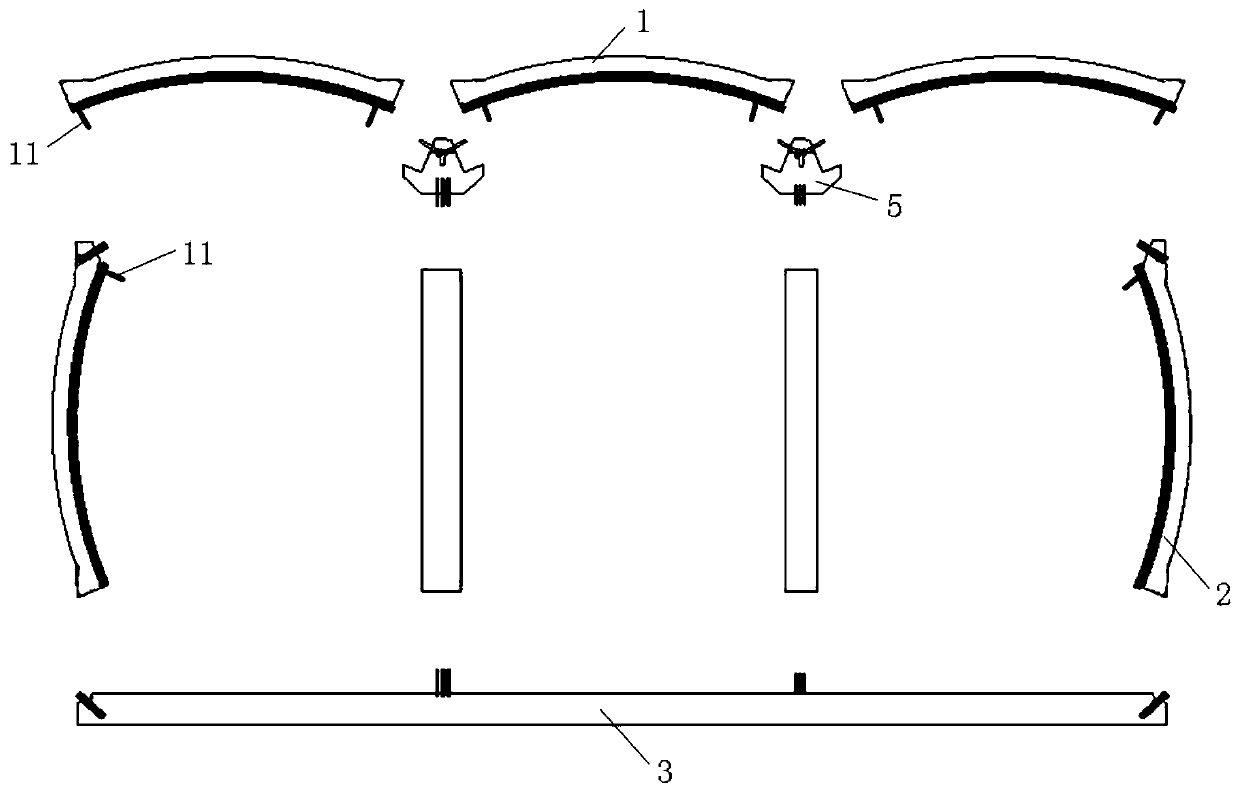

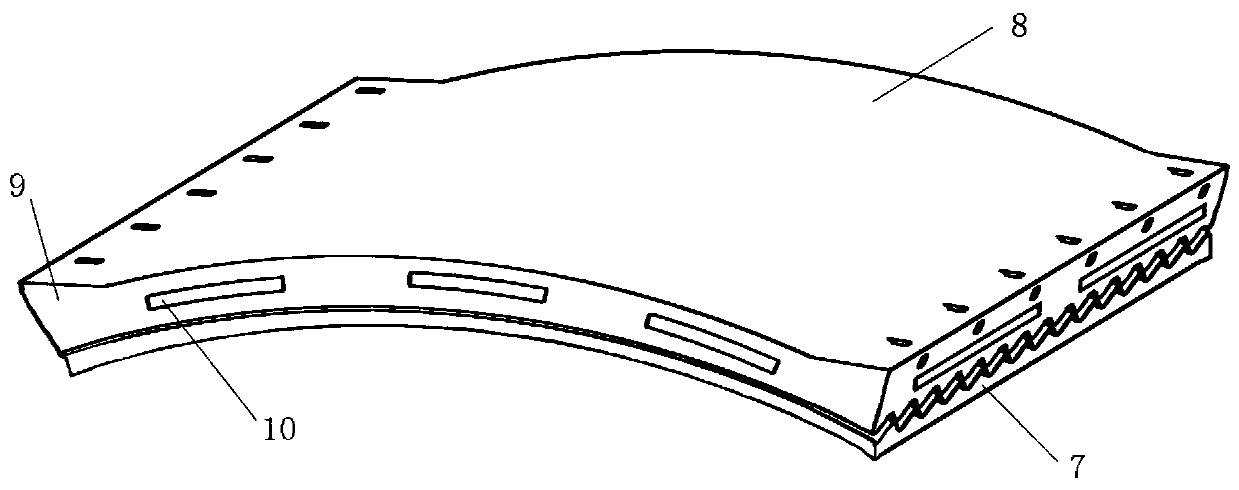

[0021] Specific implementation mode 1: The prefabricated corrugated steel concrete composite pipe gallery in this implementation mode includes 2 lateral shallow arches 2, multiple upper side shallow arches 1, prefabricated floor 3, prefabricated partitions 4 and prefabricated longitudinal beams 5, the The lateral shallow arch 2 and the upper shallow arch 1 are formed by pouring reinforced concrete 8 on the outer surface of the corrugated steel plate arch 7. There are multiple bolt holes on the left and right edges of the upper shallow arch 1, and the prefabricated bottom plate 3 There are lateral shallow arches 2 respectively arranged on the left and right sides of the side arch 2, a plurality of bolts are arranged on the upper edge of the lateral shallow arch 2, and a plurality of prefabricated partitions 4 are arranged on the upper surface of the prefabricated bottom plate 3 at intervals, and the prefabricated partitions 4 The top surface is provided with a prefabricated long...

specific Embodiment approach 2

[0025] Embodiment 2: This embodiment differs from Embodiment 1 in that the surface of the corrugated steel plate arch 7 is poured with reinforced concrete 8 with a thickness of 100-200 mm.

specific Embodiment approach 3

[0026] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the prefabricated spacer 4 is a partition (wall) or a column.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com