Spray forming method for implementing combustion similarity of diesel engine

A diesel engine, similar technology, applied in the direction of fuel injection device, engine test, machine/structural component test, etc., can solve the problems of lack of theoretical demonstration process, no summary of spray design method, etc., to reduce cost and strong feasibility , high economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

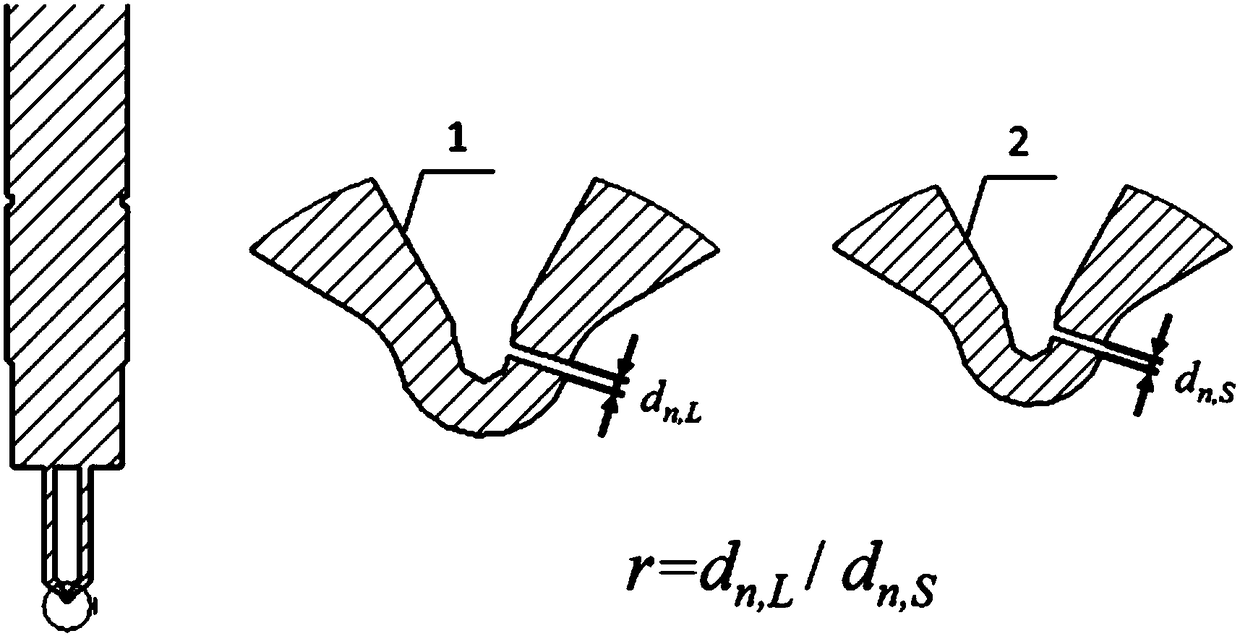

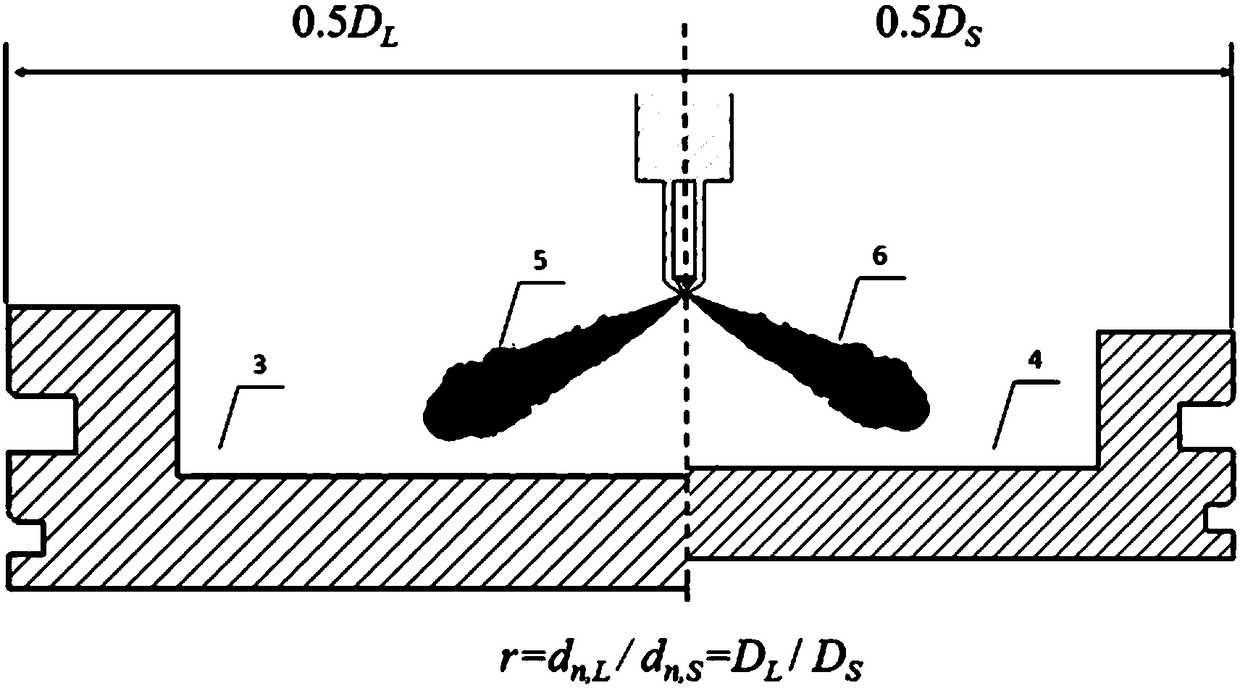

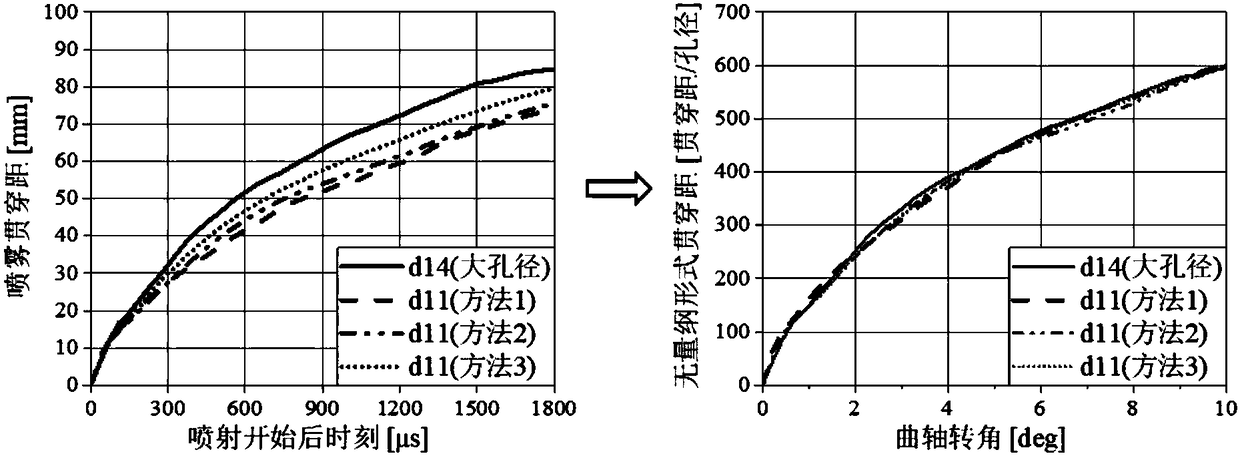

[0089] Embodiment: The spray forming method for realizing diesel engine combustion similarity provided by the present invention can be specifically realized by three special methods in the following table:

[0090]

[0091]

[0092] In the table: ρ a,L is the ambient gas density of the combustion chamber 3 corresponding to the large-aperture fuel injector;

[0093] ρ a,S is the ambient gas density of the small-aperture fuel injector corresponding to the combustion chamber 4 .

[0094] Among them, the proportion value in method 1 is special when the fuel injection duration of the large-aperture injector 1 and the small-aperture injector 2 are the same; The flame floating length of injector 2 is the same; the proportion value in method 3 is special because the injection pressure of the large-aperture injector 1 and the small-aperture injector 2 are the same.

[0095] Taking two single-hole Delphi injectors with 0.14mm and 0.1mm apertures as an example, the injection pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com