Sensor with dual-way backup signal

A sensor and sensor body technology, applied in the field of sensor technology, can solve the problems of the limitation of the resolver sensor, the poor accuracy of the magnetic sensor, and the inability to continue to operate, and achieve the effect of ingenious implementation, fast response time, and reducing the probability of failure to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

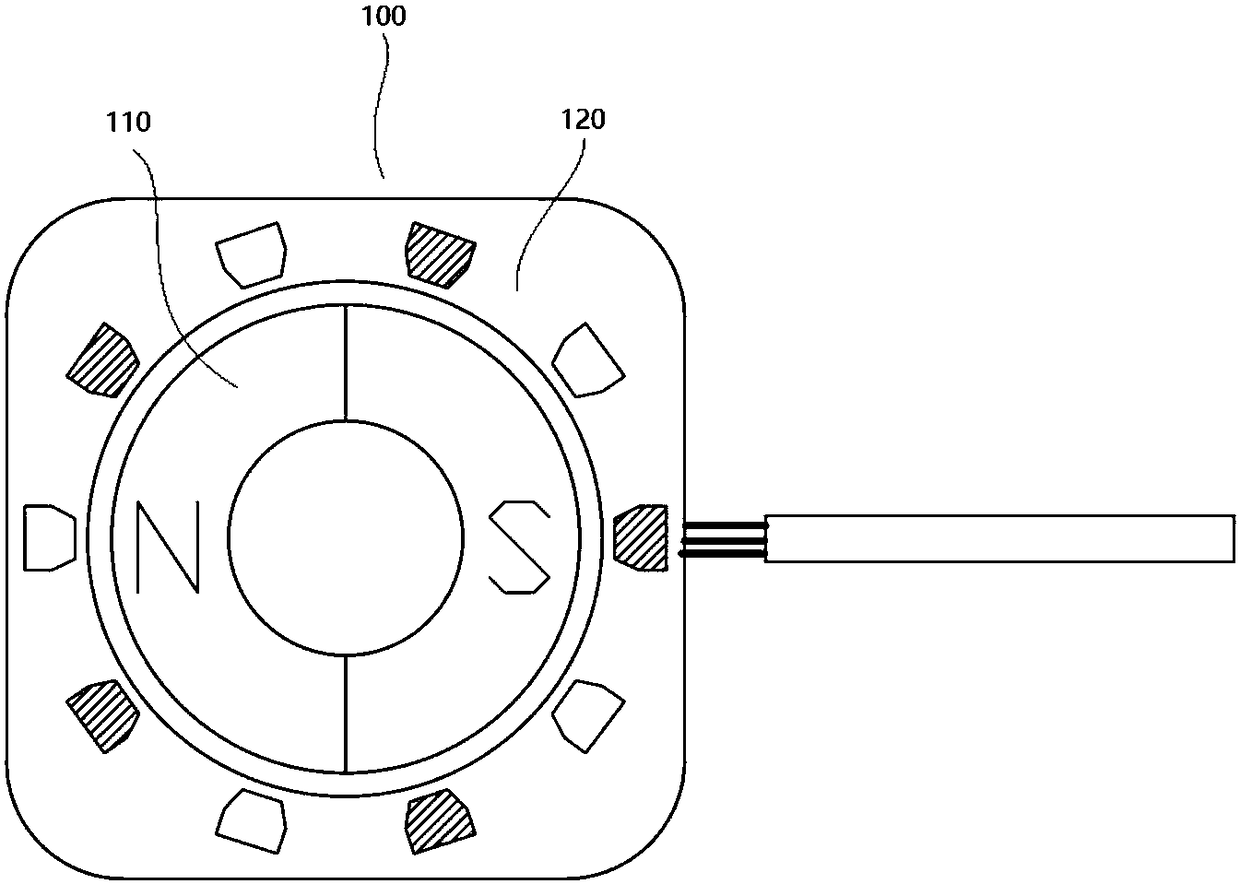

[0030] see figure 1 , which shows the basic structure of a sensor with dual backup signals for a permanent magnet synchronous motor in an example of the present invention.

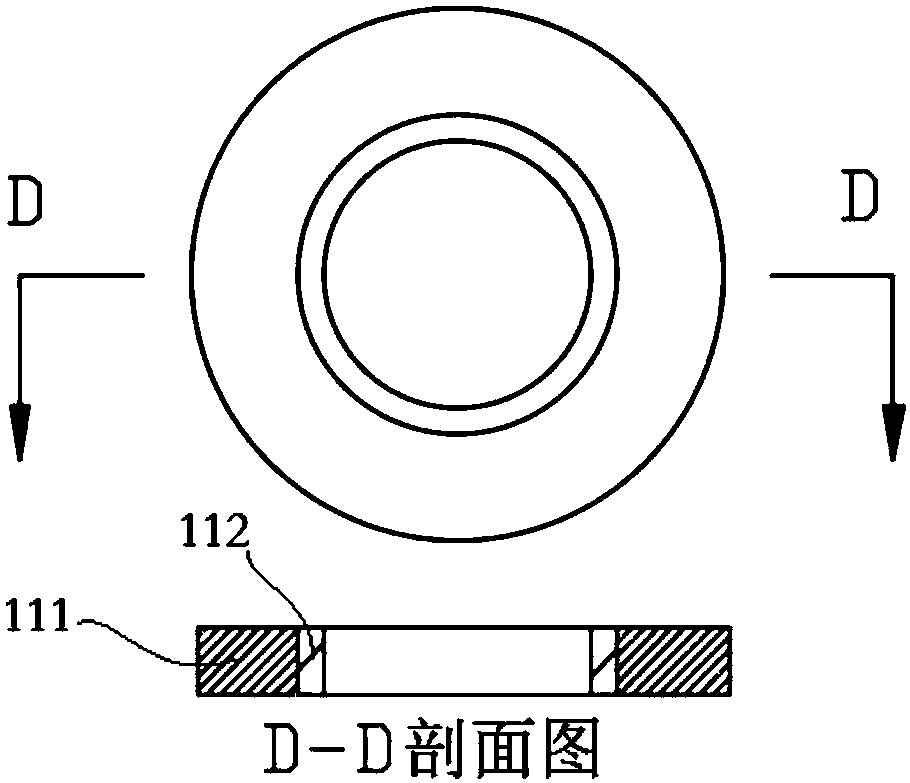

[0031] It can be seen from the figure that the sensor 100 for permanent magnet synchronous motor with automatic pole alignment function in this example mainly includes a ring magnetic encoder 110 and a sensor body assembly 120 .

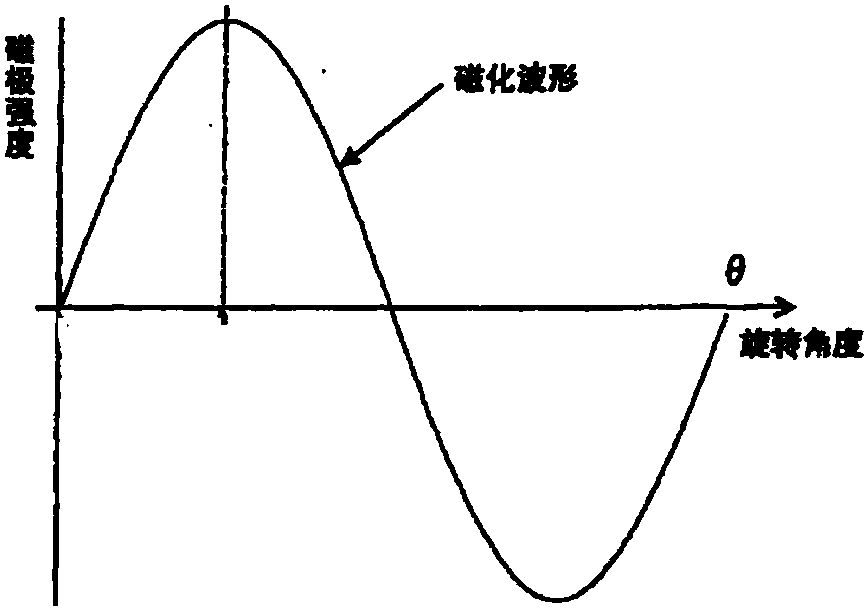

[0032] Among them, the magnetic field of the annular magnetic encoder 110 is sinusoidally distributed within a period (multiple periods can be set within 360 degrees of a week), and it is non-contact embedded in the sensor body assembly 120, and can be placed on the sensor body assembly with the target object. Rotates in 120 degrees.

[0033] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com