Annular laser resonant cavity diaphragm adjustment system and adjustment method thereof

A technology of laser resonator and ring resonator, which is applied to lasers, laser components, phonon exciters, etc., can solve problems such as difficult assembly results, reduce the influence of human subjective factors, and achieve accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the drawings and specific embodiments.

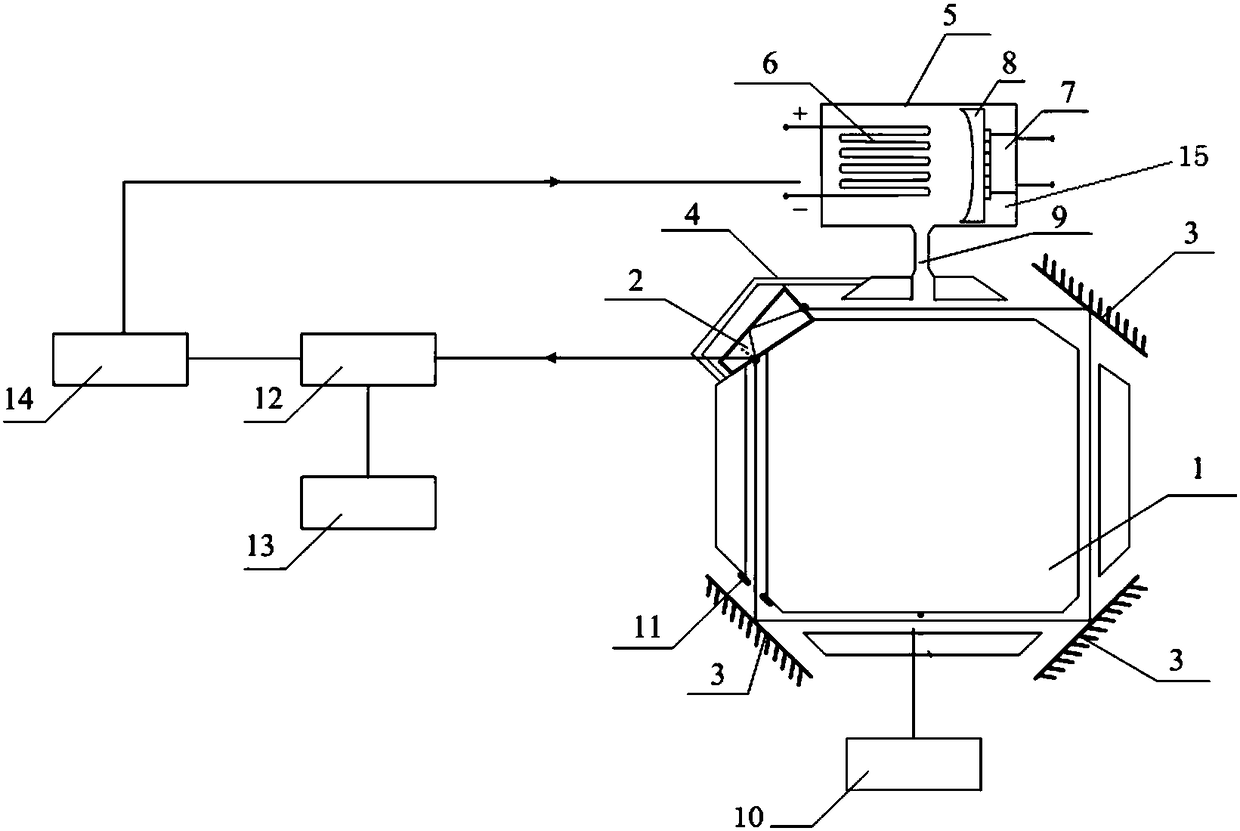

[0022] The present invention is a ring laser resonator diaphragm installation and adjustment system, such as figure 1 As shown, it includes a ring resonator cavity 1 to be assembled fixed on a base. A laser pump source 10 is arranged outside the side of the ring resonator cavity 1 filled with He-Ne gain gas. A prism 2 is arranged on one corner of the cavity 1, and a mirror 3 is arranged on the other three corners of the ring resonator cavity 1, and a patch outer diaphragm 11 is installed on the inner side of any mirror 3, along the prism 2 A photodetector 12 is provided in the horizontal direction of the emitted laser beam. The photodetector 12 is supported by a three-dimensional adjusting bracket 13. The photodetector 12 is connected with a laser frequency control box 14 through a wire, and the laser frequency control box 14 is connected with a frequency serv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com