Reflective transparent screen and image projection apparatus provided with same

A transparent screen and reflective technology, which is applied in image communication, projection devices, diffuser elements, etc., can solve the problems of unsuitable transparent partitions and low screen transparency, and achieve clear images, large viewing angles, and hot spots weak effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

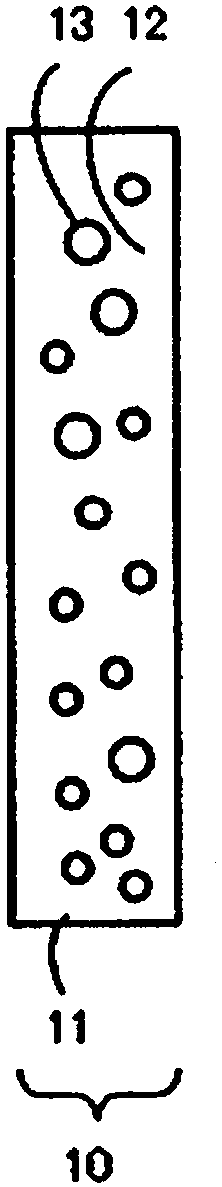

[0162] Polyethylene terephthalate (PET) particles (manufactured by Bell Polyester Co., Ltd., brand IFG8L) and 0.012% by mass of flaky aluminum particles A (light-reflecting particles, primary The particles had an average diameter of 1 μm, an aspect ratio of 300, and a specular reflectance of 62.8%) were mixed with a tumble mixer for 30 minutes to obtain PET particles uniformly adhered to the surface of flaky aluminum. The obtained pellets were supplied to a hopper of a twin-screw kneading extruder equipped with a wire drawing die, and a masterbatch mixed with flake-shaped aluminum was obtained at an extrusion temperature of 250°C. Mix the obtained masterbatch and PET granules (brand IFG8L) uniformly at a ratio of 1:2, put them into the hopper of a single-screw extruder equipped with a T-shaped die, and extrude at an extrusion temperature of 250 ° C to produce a thickness of 75 μm membrane. Since the concentration of flaky aluminum particles in the film is 0.004% by mass, when...

Embodiment 2

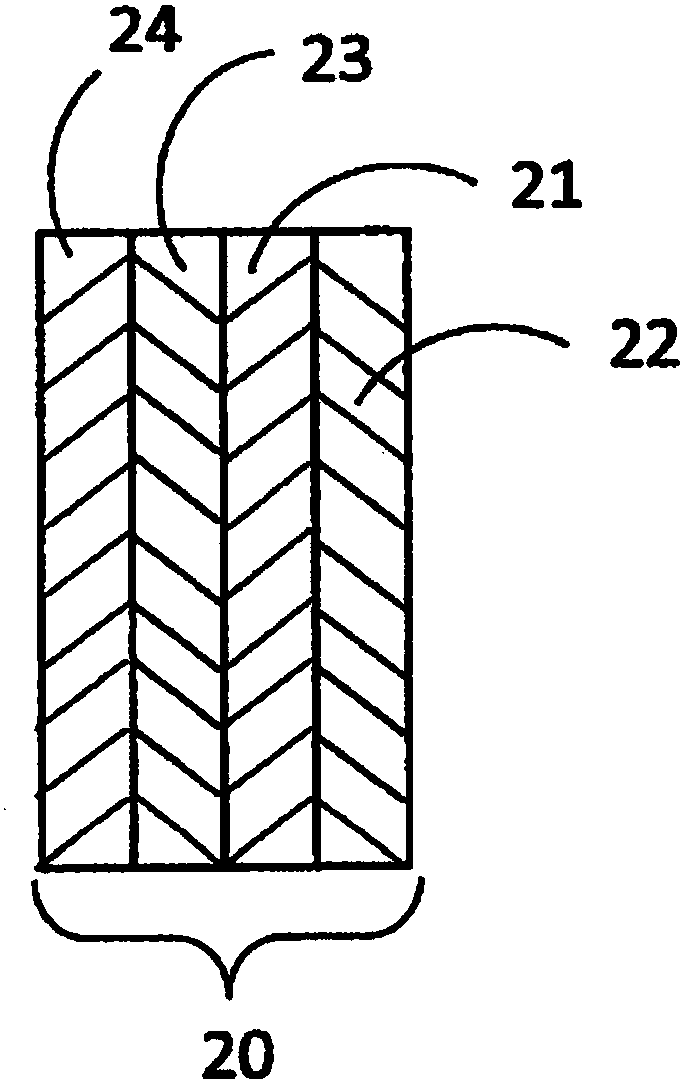

[0166] A commercially available low-reflection film (manufactured by NOF Corporation, ReaLook 2702UV / NP-50) was bonded to the film (light-diffusing layer) side of the transparent screen obtained in Example 1 to obtain a transparent screen.

[0167] The total light transmittance of the obtained transparent screen was 90.2%, the parallel light transmittance was 85.9%, the visual reflectance Y was 2.5%, and the sharpness of image was 96%.

[0168] In addition, the diffuse reflection luminance spectrum of the transparent screen was measured by using a variable angle spectrophotometer. The result: when the incident light is at an angle of 45 degrees relative to the parallel direction of the screen surface, the diffuse reflection light in the regular reflection direction (135 degrees) When the brightness is 100, the relative brightness of diffusely reflected light at 60 degrees is 0.005, the relative brightness of diffusely reflected light at 90 degrees is 0.014, and the relative brigh...

Embodiment 3

[0170] PET pellets (manufactured by Bell Polyester Co., Ltd., brand IFG8L) and 0.005% by mass of flaky aluminum particles A relative to the PET pellets were mixed with a tumbler mixer for 30 minutes to obtain a PET with flaky aluminum uniformly adhered to the surface. particles. The obtained pellets were supplied to a hopper of a twin-screw kneading extruder equipped with a wire drawing die, and extruded at an extrusion temperature of 250° C. to obtain a flake-shaped aluminum-mixed masterbatch. Mix the obtained masterbatch and PET pellets (brand IFG8L) uniformly at a ratio of 1:4, put them into the hopper of a single-screw extruder equipped with a T-shaped die, and extrude at an extrusion temperature of 250°C to produce a product with a thickness of 50 μm membrane. Since the concentration of flaky aluminum particles in the film is 0.001% by mass, when the thickness of the film (light diffusion layer) is t (μm) and the concentration of flaky aluminum particles relative to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com