Combined knife blade type terrain-self-adaptation furrowing machine

A ditching machine, self-adaptive technology, applied in the direction of self-adaptive control, excavation/covering ditches, applications, etc., can solve the production cost and increase the time to replace the ditching machine, the ditching effect is not obvious, and affect drainage and irrigation To avoid uneven ditching depth, clear soil effect and improve ditching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

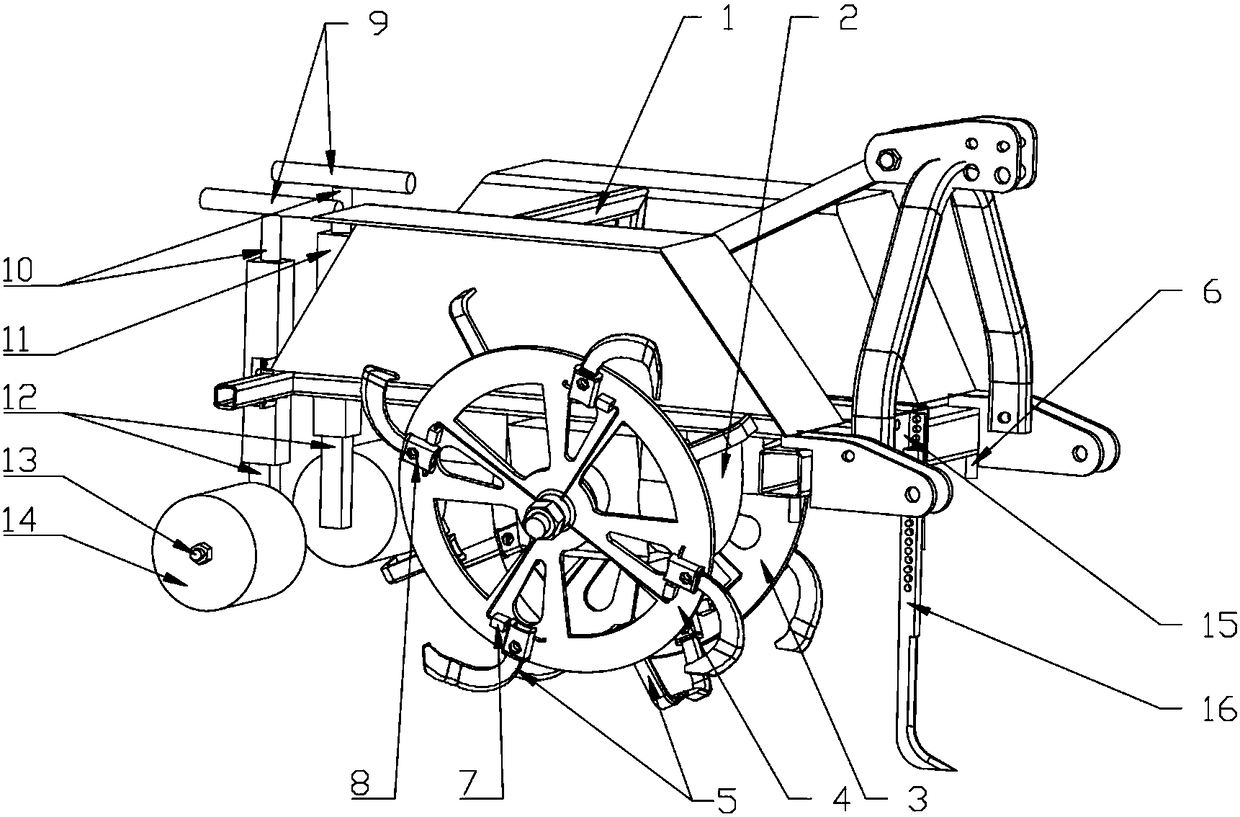

[0024] Such as figure 1 as shown, figure 1 This invention proposes a combined blade type terrain adaptive ditching machine.

[0025] refer to figure 1 , the combined blade type terrain self-adaptive ditching machine that the present invention proposes, comprises: frame 1, ditching mechanism, terrain detection device 6, depth limit adjustment device; Ditching mechanism, terrain detection device 6 and depth limit adjustment device are all installed on rack 1;

[0026] The ditching mechanism includes a subsoiling device, a split gear box 2, a first strip-shaped circular cutter head 3, a second strip-shaped circular cutter head 4, a combined ditching blade 5, a terrain detection device 6, and blade angle adjustment Device 7; the subsoiling device is installed on the frame 1, the split gearbox 2 is fixed on the frame 1 by bolts, and the first strip-shaped circular cutter head 3 and the second strip-shaped circular cutter head 4 are oppositely installed on the On the split gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com