Long-stroke low-damage corn niblet threshing device and method

A threshing device and low-damage technology, which is applied in threshing equipment, applications, agricultural machinery and machinery, etc., can solve the problems that hinder the development of mechanized harvesting technology of corn kernels, limit the length of threshing drums, and high corn kernel crushing rate, etc., so as to increase the impact The number of times and kneading time, the effect of improving production efficiency and cleaning rate, and reducing the rate of grain breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

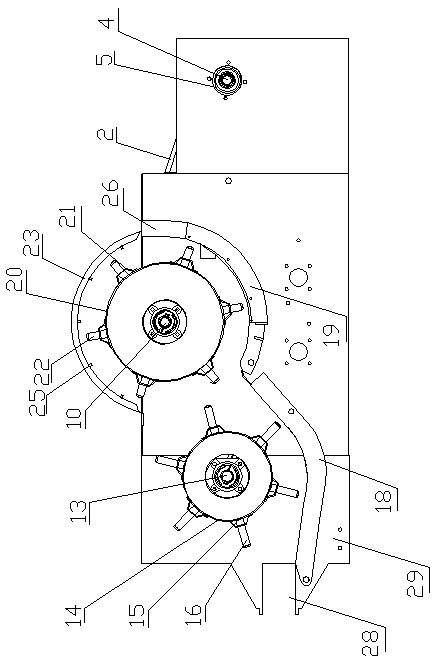

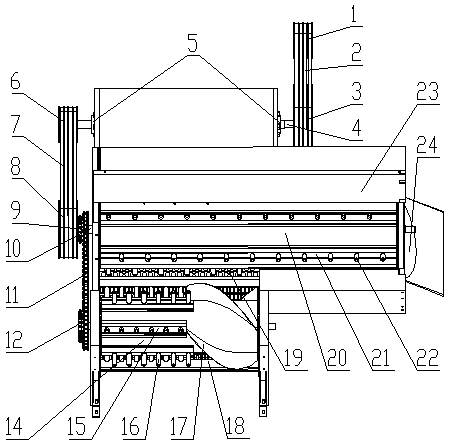

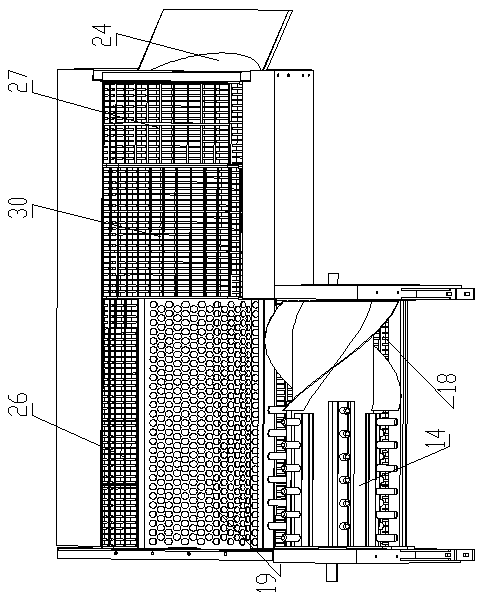

[0038] A long-stroke low-damage corn kernel threshing device, such as Figure 1~4 Shown, comprise body 29, establish transmission part, feeding part and threshing separation part on body 29.

[0039] In this embodiment, the definition of front, back, left and right is as follows: figure 2 The orientation in is defined: figure 2 The left and right in the figure are the left and right in this embodiment. figure 2 The upper and lower in the figure are respectively the rear and the front in this embodiment.

[0040] Among them, the transmission part provides kinetic energy for the work of the body 29, ensuring the normal operation of the feeding part and the threshing and separating part in the body 29; Separation of cobs.

[0041] A feeding port 28 is provided on the left end of the body 29, and a feeding drum 14 located in the body 29 is arranged adjacent to the feeding port 28, wherein the transmission part drives the feeding drum 14 to rotate.

[0042] Feeding spikes 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com