Nozzle for blowing filtering dust collector

A technology for filtering dust collectors and nozzles. It is applied in the fields of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation. It can solve problems such as unsatisfactory dust removal effect, uneven airflow distribution, and complex mold structure, and achieve the effect of spray dust removal. Excellent, improve the efficiency of spray dust removal, the effect of simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

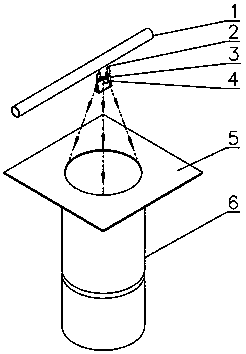

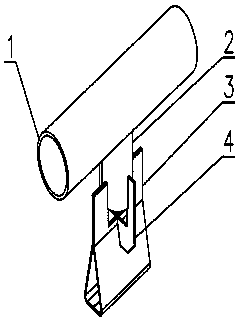

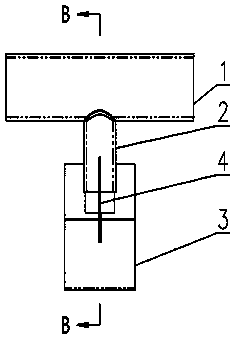

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, this technical solution adopts the aluminum blowing pipe 1 as the air source pipe, drills a φ28 air outlet on it, and welds the nozzle conduit 2, the nozzle support plate 3 and the nozzle splitter plate 4 of the cross structure, and is used for blowing and filtering the dust collector. The air outlet of the nozzle is to use the pulse system to control the pull-in of the solenoid valve. The pulse system program gives the signal to the solenoid valve and pulls the solenoid valve to make the air flow out through the nozzle. The air flow passes through the nozzle support plate 3 and the nozzle splitter plate 4 to evenly Divide into four equal parts, and spray them evenly on the filter bag 6 to remove the attached dust. The airflow angle of the four equal parts should be set within the required range of the orifice plate 5 of the filter bag to achieve dust removal. The effect of dust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com