Multifunctional plate bending machine for construction

A plate rolling machine and multifunctional technology, which is applied in the field of multifunctional plate rolling machines for construction, can solve the problems of waste, a lot of manpower and material resources, and short use cycle of construction sites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

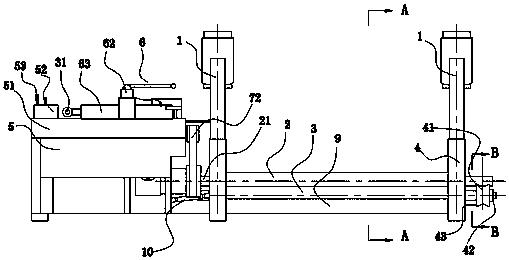

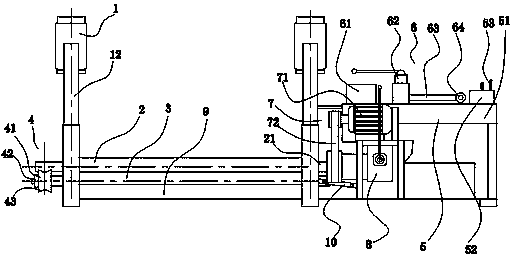

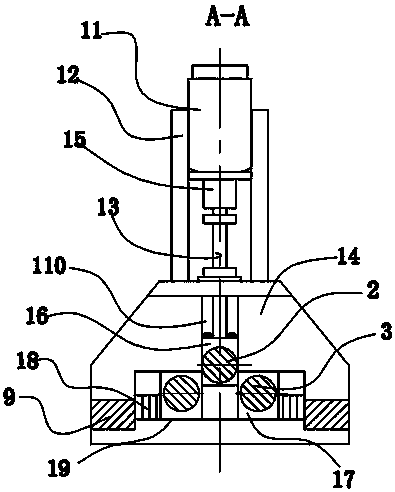

[0021] see Figure 1-Figure 5 As shown, the technical solution adopted in this specific embodiment is: it consists of two plate bending machine columns 1, an upper roller 2, two lower rollers 3, a side circular die set 4, a bending workbench 5, and a hydraulic workbench 6. The main driving device 7, the clutch 8, and the main beam 9 are composed. The two columns 1 of the plate bending machine are fixedly connected by the two main beams 9. The upper roller 2 and the two lower rollers 3 are arranged between the two columns 1 of the plate bending machine. , the two lower rollers 3 are arranged side by side, the upper roller 2 is arranged above the middle position of the two lower rollers 3; the side circular die module 4 is arranged on the right side of the right column of the plate rolling machine column 1 and is coaxial with the two lower rollers 3 The main driving device 7 is provided with the left side of the left column of the coiling machine column 1, the main driving devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com